Directly-series-connected one-step pressure variation adsoption process

A pressure swing adsorption, tandem technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as large venting, incomplete separation, and large system footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

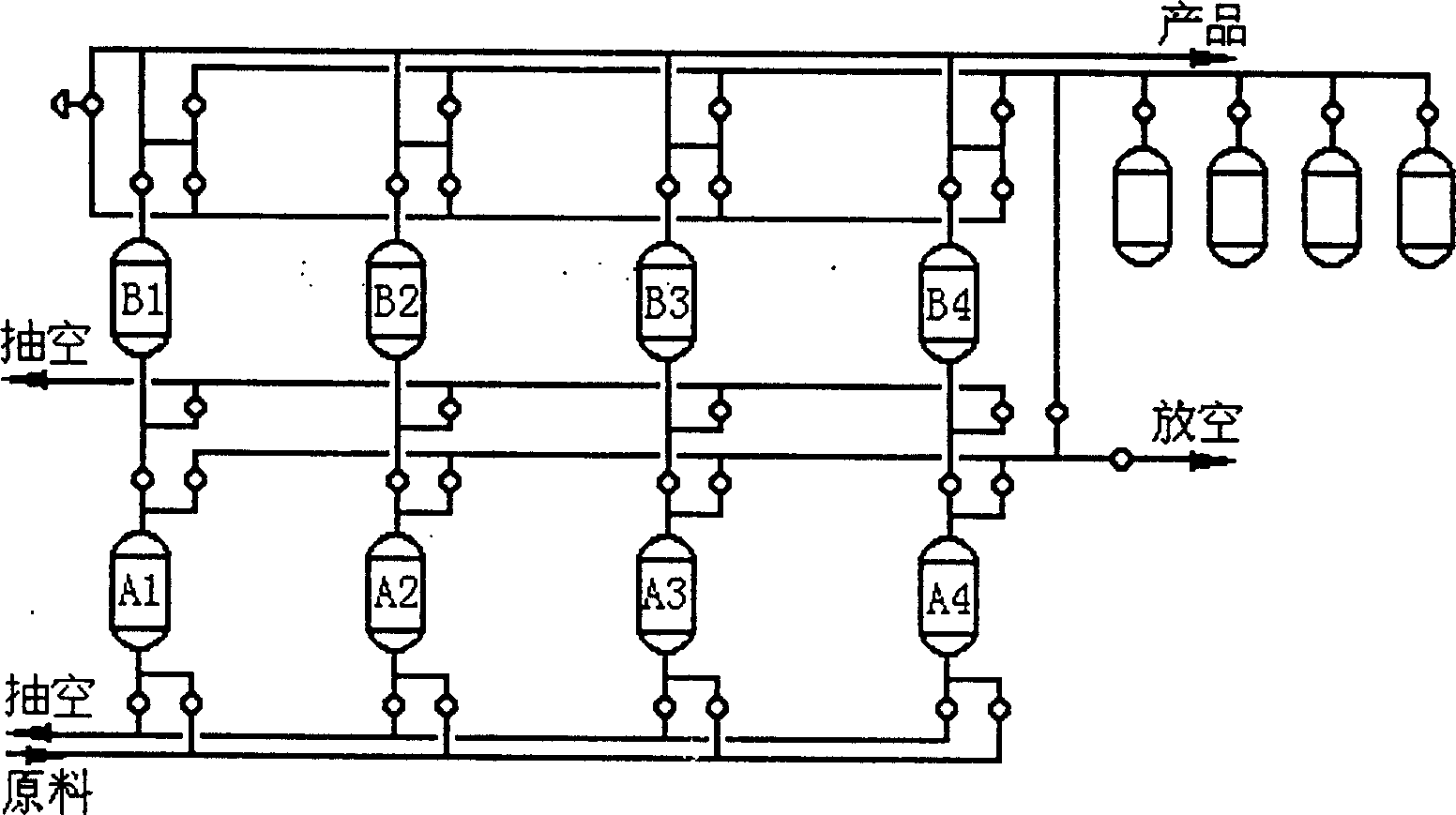

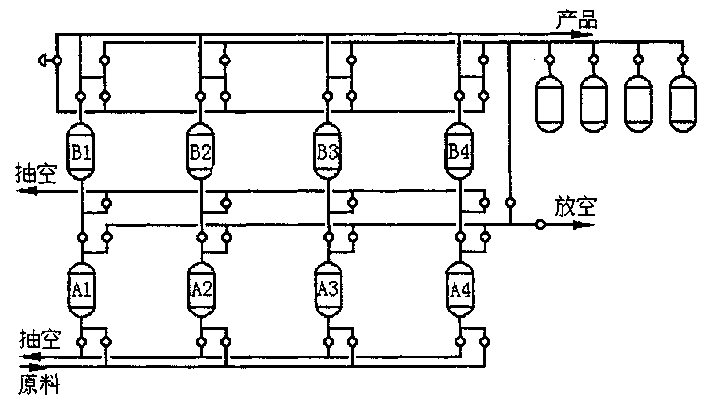

Embodiment 1

[0017] This embodiment is a direct series pressure swing adsorption process for the extraction of hydrogen from semi-water gas. The raw material pressure is 0.7MPa gauge pressure. This embodiment adopts the 4-082224 process, that is, the system has four groups of eight tower processes, the two towers are directly connected in series, two stages are independently evacuated, two direct pressure equalization, four indirect pressure equalization. Table 1 is a quarter process timing table of this embodiment, and the rest can be deduced by referring to the table sequence.

[0018] A1

Primary adsorption

A2

One to five pressure drops

Liu Junjiang

Put in order

Smooth draw

Reverse draw

A3

Reverse pumping

Liu Junsheng

Five to one pressure rise

A4

Equal pressure rise

Final charge

B1

Secondary adsorption

B2

One to five times pressure drop

Liu Junjiang

Reverse draw

B3

Reverse draw ...

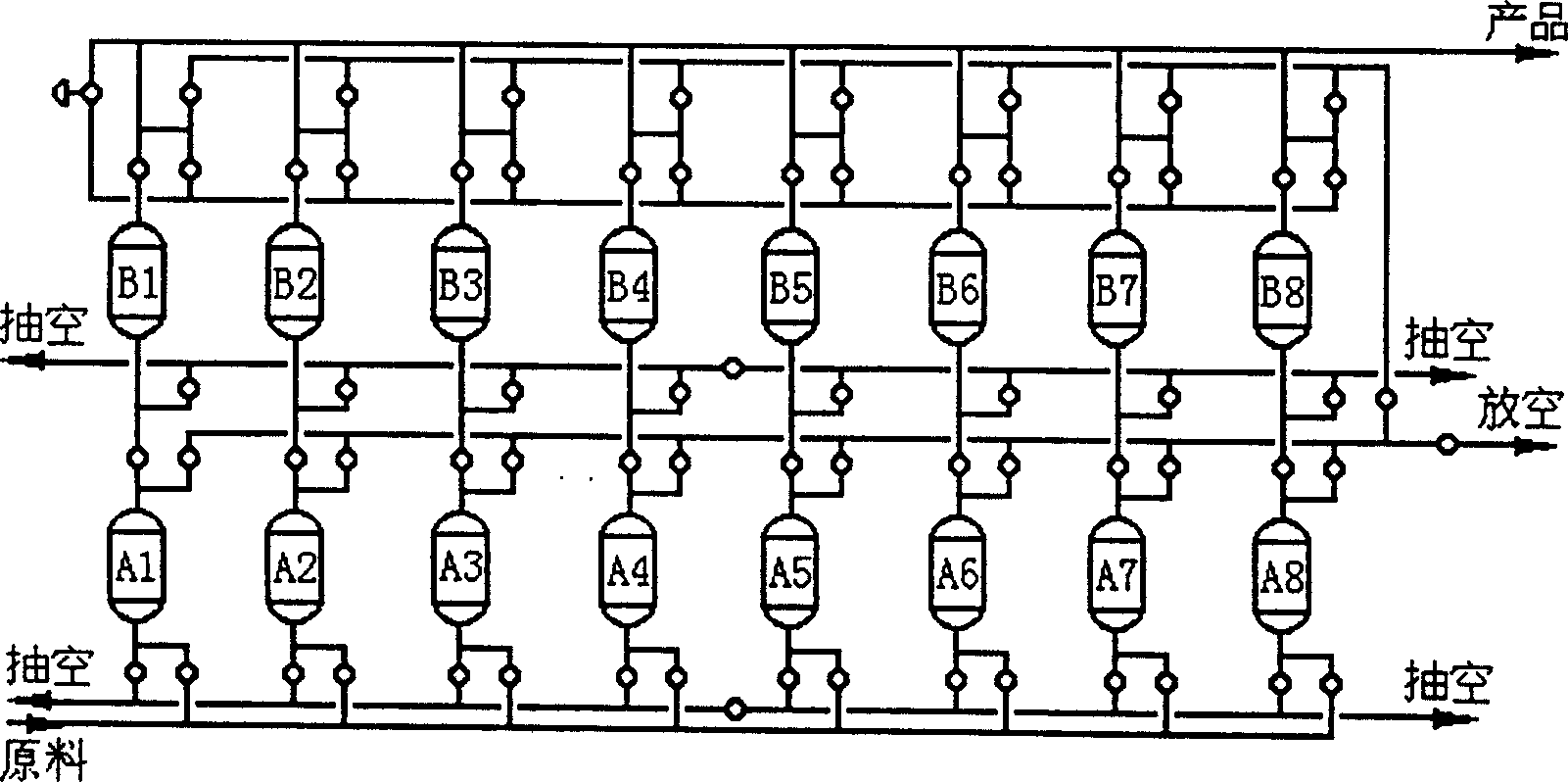

Embodiment 2

[0029] This embodiment is a direct series pressure swing adsorption process for separating carbon dioxide from shift gas in urea production. The raw material pressure is 1.6MPa gauge pressure. This embodiment adopts the 8-164440 process, that is, the system has eight groups of sixteen tower processes, four towers are connected in series with two sets of air intake, four towers are evacuated at the same time, four direct pressure equalization is performed, and there is no indirect pressure equalization process. Table 2 is the one-eighth process timing table of this embodiment, and the rest can be deduced according to the order of the table.

[0030] A1

Primary adsorption

A2

All drop

Isolate

Both drop

A3

Isolate

All three

A4

Isolate

All four

Put in order

Reverse pumping

A5

Reverse draw

A6

Reverse pumping

All four

Isolate

Sanjunsheng

Erjunsheng

A7

All up

Final ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com