Concentration system and method for isoleucine extraction process

An extraction process, isoleucine technology, applied in the field of concentration system in the isoleucine extraction process, to achieve low consumption, stable heat exchange effect, and improve concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

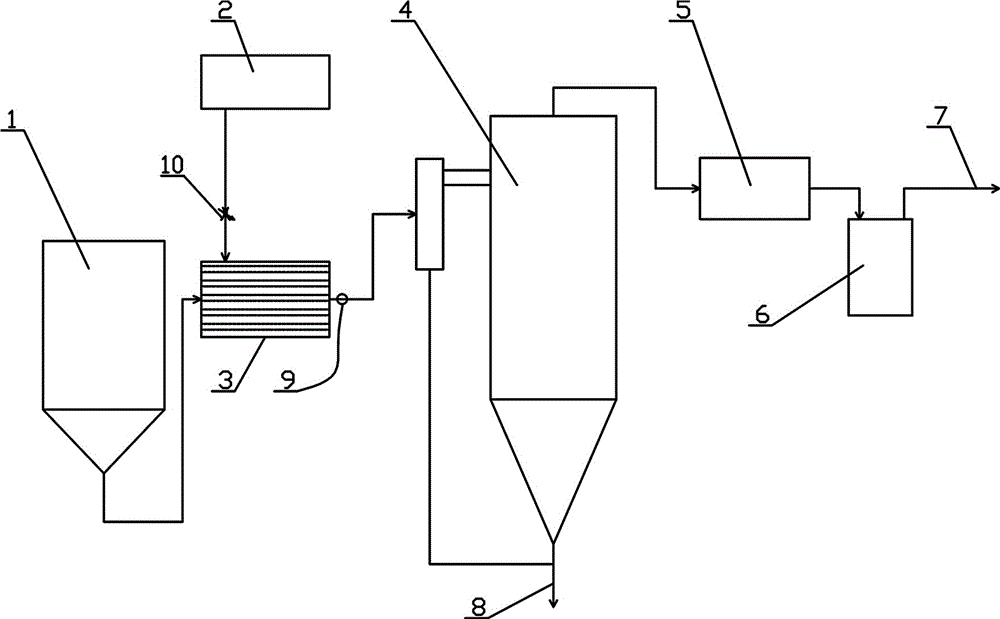

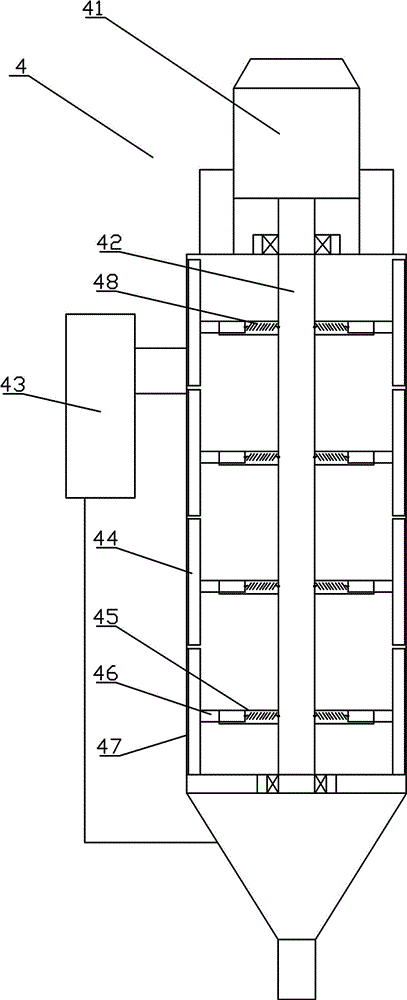

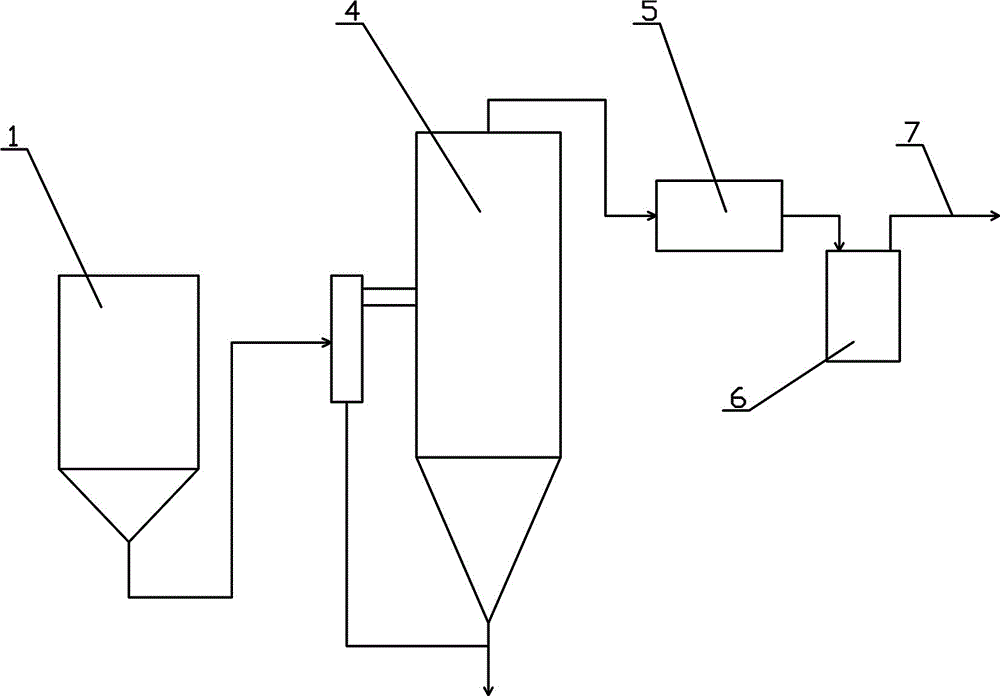

[0028] Such as figure 1 Among them, a concentration system used in the isoleucine extraction process, the liquid outlet of the desorption liquid storage tank 1 is connected to the tube side of the heat exchanger 3 through a pipeline, and the tube side of the heat exchanger 3 is connected to the tube side of the concentrator 4 The liquid inlet is connected, and the shell side of the heat exchanger 3 is connected with the steam tail gas pipeline. With this structure, the isoleucine desorption solution is heated and then enters the concentrator 4 for concentration, which improves the concentration efficiency.

[0029] preferred as figure 1 Among them, the shell side of the heat exchanger 3 is connected with the steam tail gas pipeline of the sterilization device 2 .

[0030] Preferably, the heat exchanger 3 is a shell and tube heat exchanger. The shell and tube heat exchanger used in this example has a heat exchange area of 18 cubic meters.

[0031] preferred as figure 1 A...

Embodiment 2

[0038] On the basis of Example 1, a method for concentrating using the above-mentioned concentrating system used in the isoleucine extraction process, the temperature of the inlet material of the heat exchanger 3 tube side, that is, the temperature of the desorption liquid is lower than the temperature of the outlet material by 8- 12°C. Preferably, the temperature of the inlet material in the tube side of the heat exchanger 3 is lower than the temperature of the outlet material by 10°C.

[0039] Preferably, the temperature of the material at the outlet of the tube side of the heat exchanger 3 is less than 37°C.

[0040] Specifically, the desorption liquid from the desorption liquid storage tank 1 enters the tube side of the heat exchanger 3, is heated by the remaining steam from the sterilization device 2 for fermentation and sterilization at 10±10°C, and enters the scraper in the concentrator 4 through the pipeline Film formation, hot air enters from the bottom of the tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com