Method and device for automatically repairing breakage of inflection point of chute

An automatic repairing and chute technology, applied in the field of chute, can solve the problems of extending the trouble-free service time of the chute and the breakage of the inflection point of the chute, and achieve the effect of extending the trouble-free running time, improving the construction efficiency and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

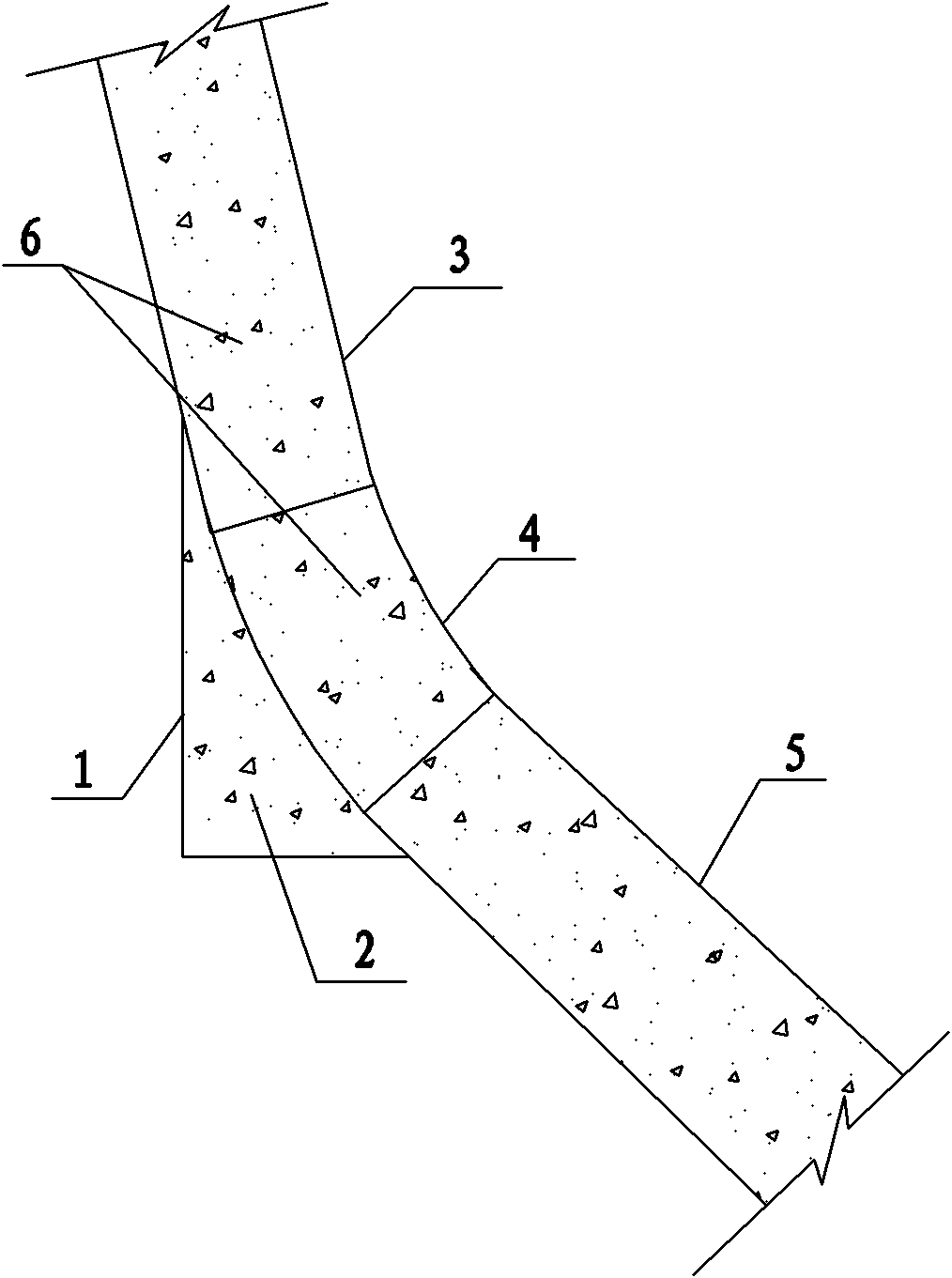

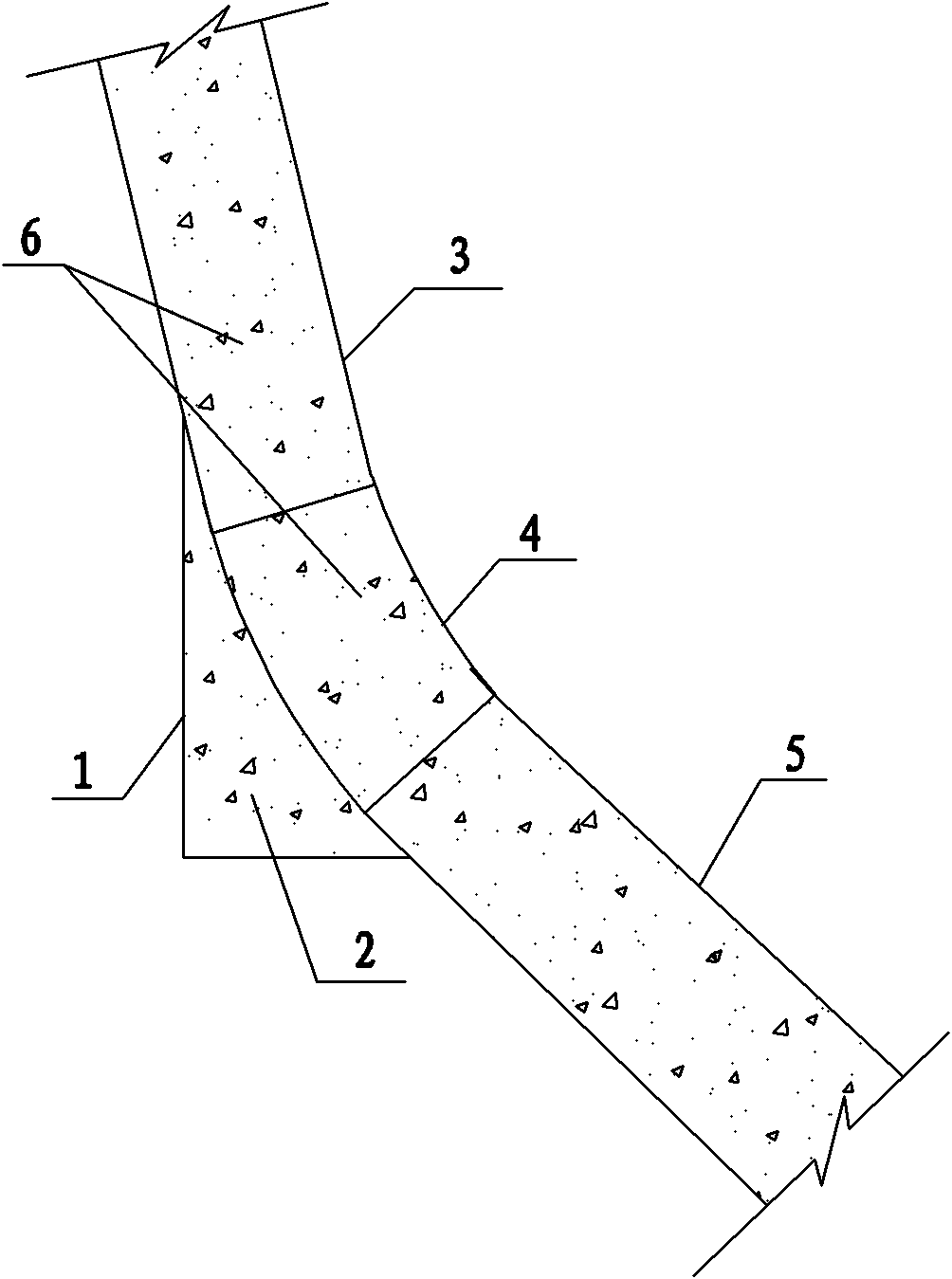

[0011] A method for automatically repairing the damage of the inflection point of a chute, comprising the following steps: installing a steel plate box 1 on the outer side of the curved section 4 of the chute, so that the steel plate box 1 completely covers the stressed curved surface on the outside of the curved section 4 of the chute, so that the chute has automatic damage to the inflection point Repaired functionality. The outer side of the curved section 4 of the chute refers to the side that bears the impact of the material during the material transport process of the chute.

[0012] A device for automatically repairing the damage of the inflection point of a chute, which comprises a chute, and a steel plate box 1 is installed on the outside of the curved section 4 of the chute.

[0013] The upper edge of the steel plate box 1 is connected with the straight section 3 of the upper chute, and the lower edge is connected with the straight section 5 of the lower chute. That ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com