Control system and method for automatically adjusting moving speed of cutting arm of cantilever type heading machine

A cantilever roadheader and self-adjusting technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as damage to electrical components and mechanical structures, overloading of cutting motors and driving cylinders, and increased load on cutting parts. , to achieve the effect of reducing energy consumption ratio, reducing wiring, and simplifying control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

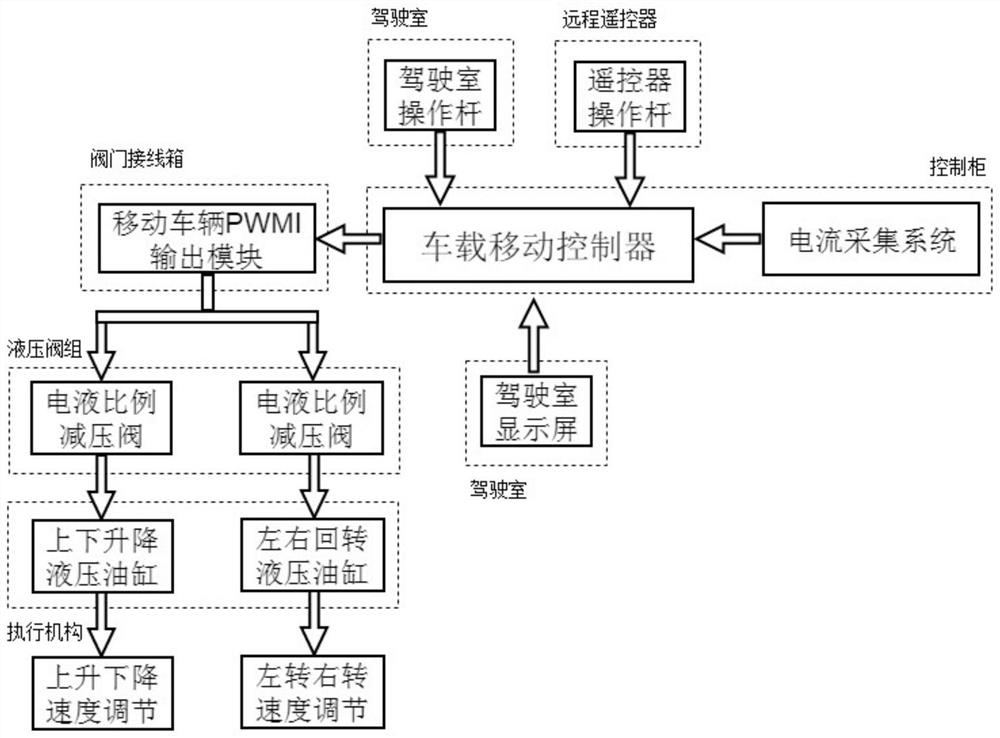

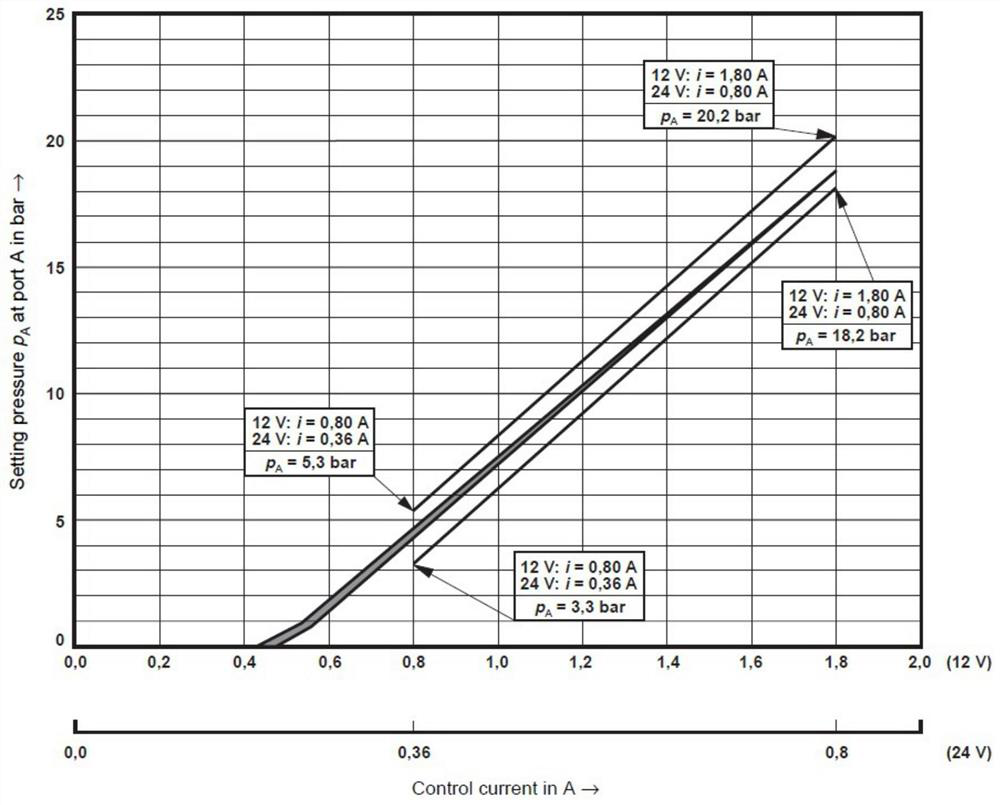

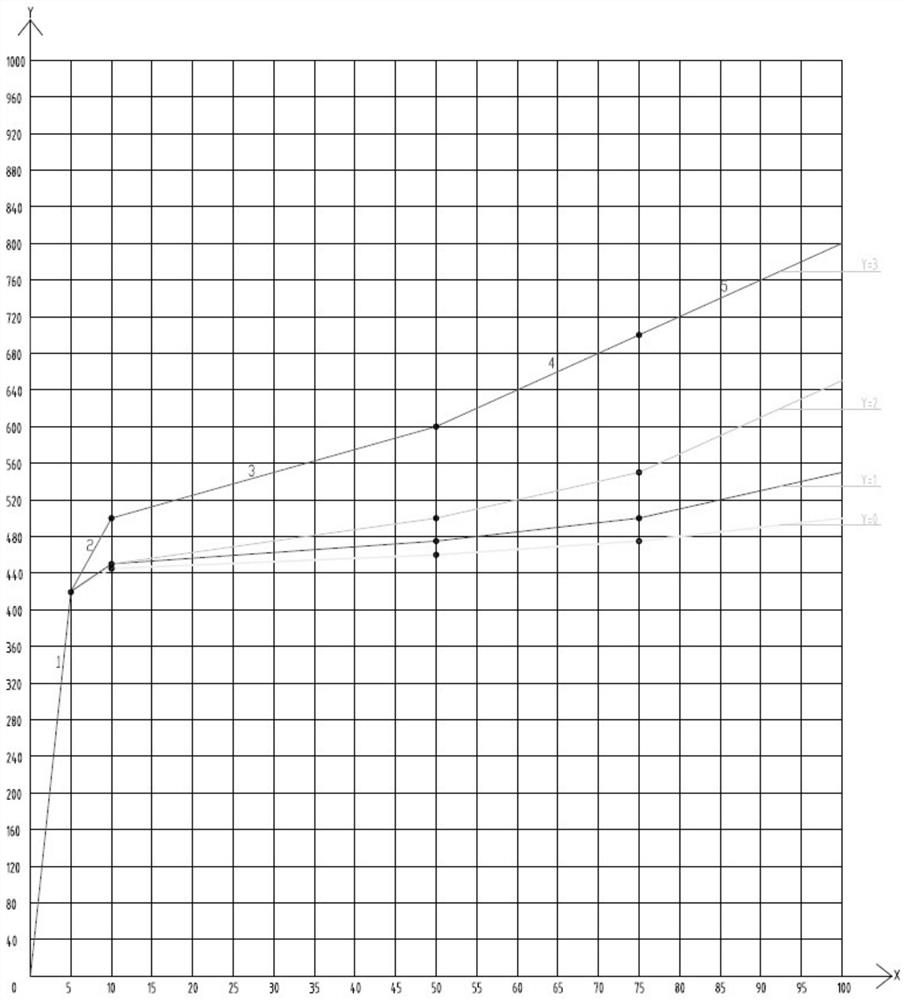

[0026] Such as figure 1 As shown, a control system for automatically adjusting the moving speed of the cutting arm of the cantilever roadheader includes: a display screen in the cab showing parameters such as current and hydraulic pressure; The double-axis operating lever with buttons; the dual-axis operating lever on the remote controller to adjust the moving speed of the cutting arm and the speed gear selection knob of the cutting arm; the processing current acquisition system with high performance and high protection level set in the control cabinet The signal vehicle-mounted mobile controller is connected to the hydraulic proportional solenoid valve driven by the PWM technology output current signal in the hydraulic valve group through the mobile vehicle PWMI output module in the valve junction box; the ascending and descending hydraulic cylinders and the left and right The four electro-hydraulic proportional pressure regulating valves of the rotary hydraulic cylinder are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com