Transmission system of mine conveying part and its torque limiting reducer and control method

A technology of transmission system and conveying part, applied in transmission, automatic clutch, gear transmission, etc., can solve the problems of complex internal structure, short service life of elastic coupling and torque shaft, overload of conveying part, etc., to improve reliability. performance and work efficiency, long trouble-free operation time, and the effect of reduced operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

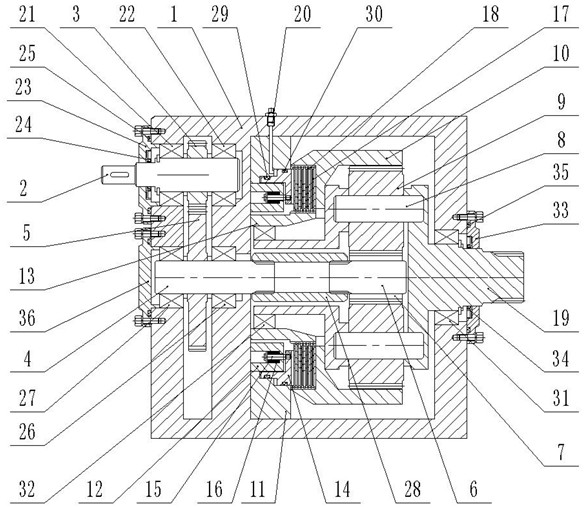

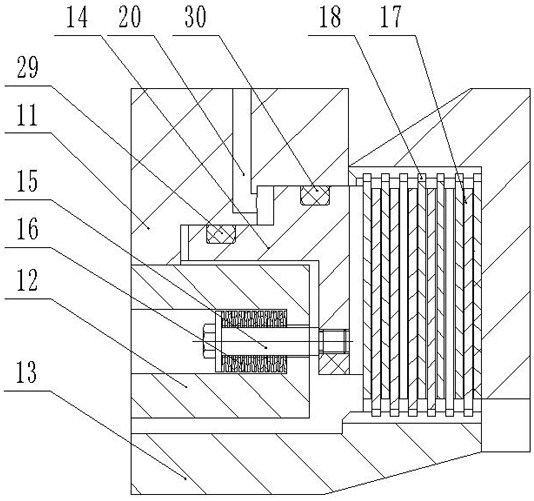

[0035]This embodiment provides a torque-limiting speed reducer for the transmission system of the mine conveying part, including a box body 1, an input gear shaft 2, an input gear 3, an intermediate gear shaft 4, an intermediate gear 5, a sun gear shaft 6, a sun gear 7, a planet Wheel shaft 8, planetary gear 9, floating ring gear 10, first support seat 11, second support seat 12, third support seat 13, piston 14, screw rod 15, disc spring group 16, static friction plate 17, dynamic friction plate 18, output Shaft 19 and planet carrier; input gear shaft 2 rotates and is installed on the box body 1, the input end is located outside the box body 1 for connection with the motor 201, input gear shaft 2 is fixedly sleeved with input gear 3; intermediate gear shaft 4 rotates Penetrated in the box 1, the intermediate gear shaft 4 is fixedly set with an intermediate gear 5, which meshes with the input gear 3, and the intermediate gear 5 is used to reduce the input speed of the input gea...

Embodiment 2

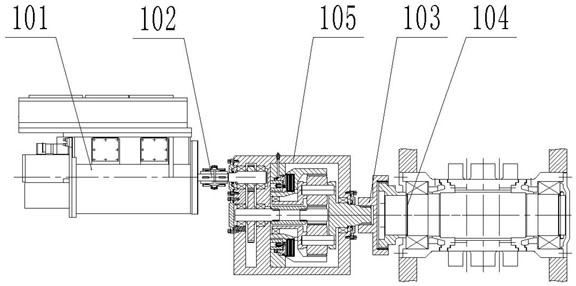

[0043] This embodiment provides a transmission system for mine conveying parts, including a motor 101, a shaft coupling 102, a transition plate 103, a sprocket 104, and the torque-limiting reducer 105 described in Embodiment 1; the motor 201 communicates with the The input gear shaft 2 of the torque limiting reducer 105 is connected; the sprocket 104 is connected with the output shaft 19 of the torque limiting reducer 105 through the transition plate 103 .

[0044] Further, the transmission system of the mine conveying part also includes a hydraulic control circuit, and the hydraulic control circuit includes a gear pump 106, a first overflow valve 107, a filter 108, a pressure gauge 109, a second overflow valve 110, and a solenoid valve 111 , throttle valve 112 and oil tank 113; the oil inlet of gear pump 106 is connected with oil tank 113, and oil outlet is connected with the first overflow valve 107 and filter 108 respectively; The first overflow valve 107 is connected back t...

Embodiment 3

[0050] This embodiment provides a control method for the transmission system of the mine conveying part, including a starting method:

[0051] S1, the motor 101 and the gear pump 106 start at the same time. When the oil does not enter the high-pressure oil passage 20, the dynamic friction plate 18 and the static friction plate 17 are separated, and the motor 101 outputs power to the input gear shaft 2. After reducing the speed through the intermediate gear 5, the The power is transmitted to the sun gear 7, the sun gear 7 drives the rotation of the planetary gear 9, the rotation of the sun gear 7 transmits the power to the planetary gear 9, the rotation of the planetary gear 9 drives the floating ring gear 10 to rotate, the dynamic friction plate 18 rotates, and the static friction plate 17 is fixed;

[0052] S2, the oil enters the high-pressure oil passage 20, overcomes the force of the disc spring group 16, and makes the piston 14 exert pressure on the dynamic friction plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com