Working condition optimization method and gas volume adjustment control system of natural gas gathering booster

An air volume adjustment and control system technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problem that the exhaust volume adjustment range is not large, the clearance value of the fixed clearance device is increased, and the displacement of the supercharger is reduced. and other problems, to achieve the effect of increasing the trouble-free running time, reducing the workload of adjustment, and reducing the frequency of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

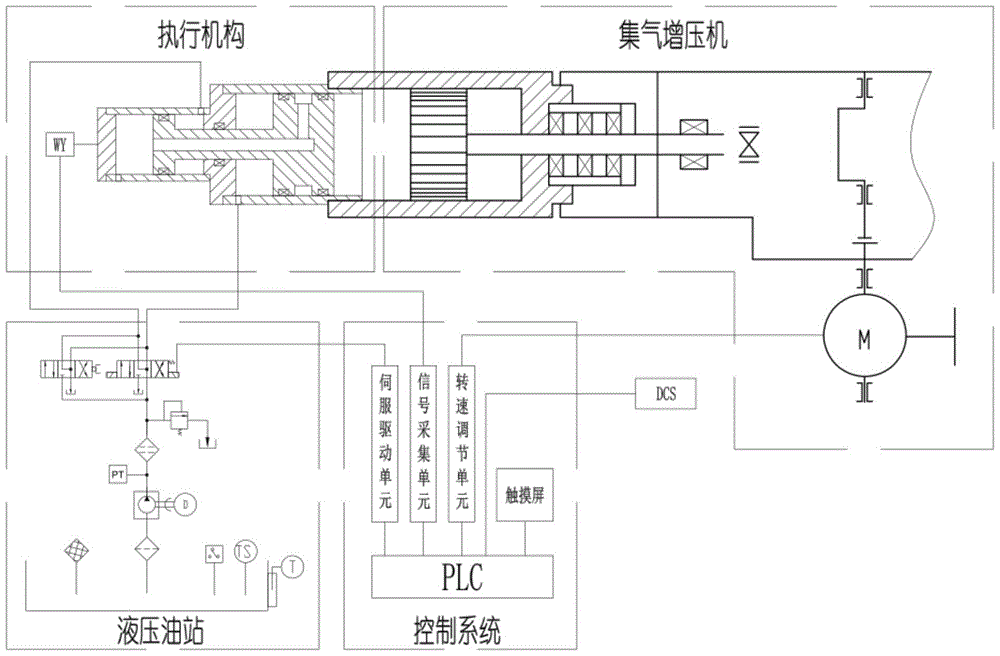

Method used

Image

Examples

Embodiment

[0031] Take a DPC-2803 gas-collecting booster with a working speed of 340rpm, an inlet pressure of 1MPa, an exhaust pressure of 2.8MPa, and an inlet flow rate of 12000Nm3 / h as an example.

[0032] Before the retrofit of the stepless adjustment of the clearance, the inlet pressure of the supercharger was significantly reduced due to the declining production capacity of the gas well in the gas gathering station. The current inlet pressure can only be maintained at 0.79MPa, and the average compression ratio is 3.5. Due to the light load of the supercharger and the high compression ratio, the exhaust temperature of the supercharger remains high (average 108°C), and the parts such as the gas valve of the supercharger suffer from serious loss. At the same time, frequent alarms are generated due to the high exhaust temperature of the unit. Shutdown will affect the natural gas production of the gas gathering station.

[0033] After the retrofit of stepless clearance adjustment, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com