Coal preparation plant main coal washing production method

A production method and coal washing technology, applied in the field of coal mines, can solve problems such as the inability to guarantee safety and high efficiency, and achieve the effects of reducing the probability of failure to stop, reducing the start-up time, and avoiding start-up interruptions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

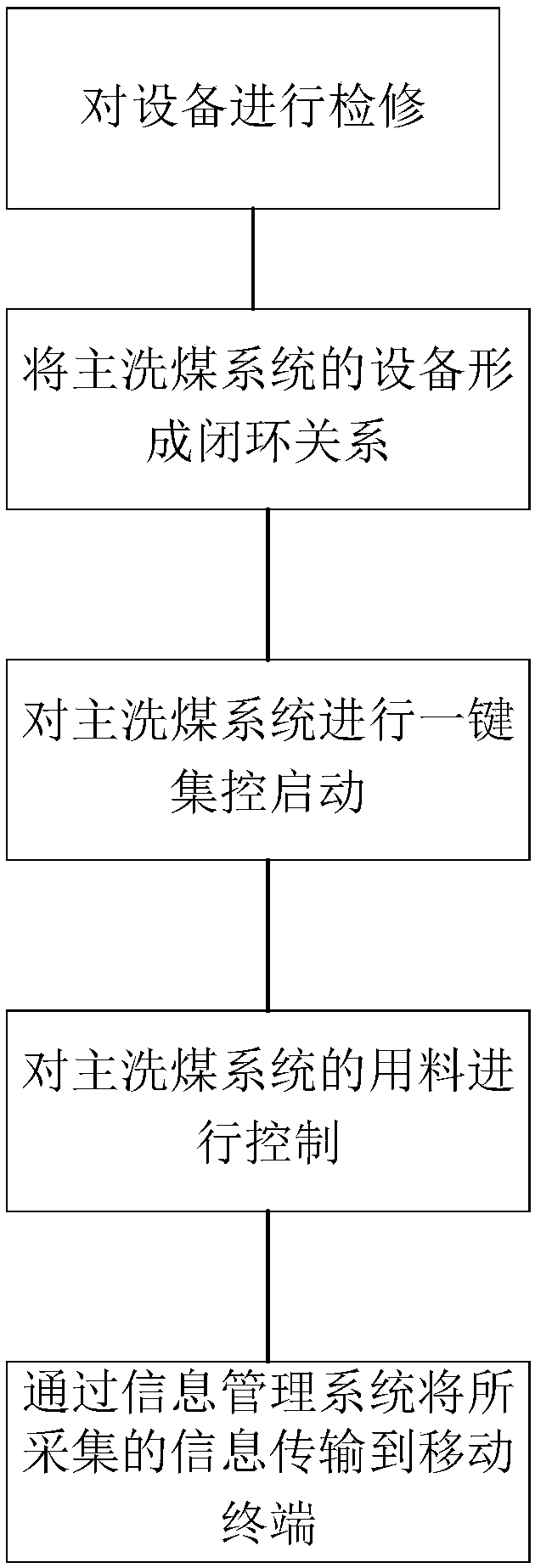

Method used

Image

Examples

example 1,,,;, 2 , 1 , 1 。,, 1 ,。 example 2

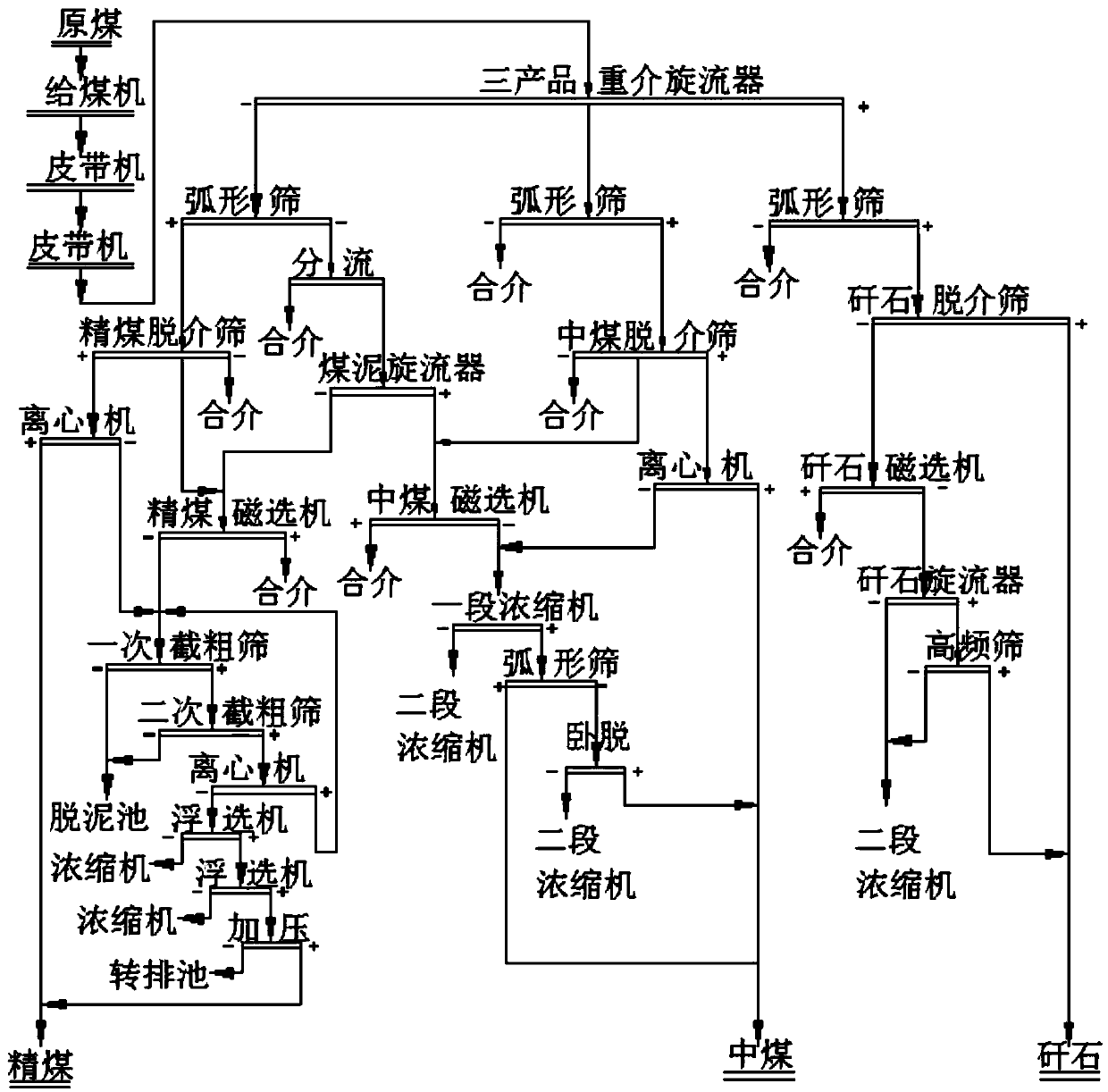

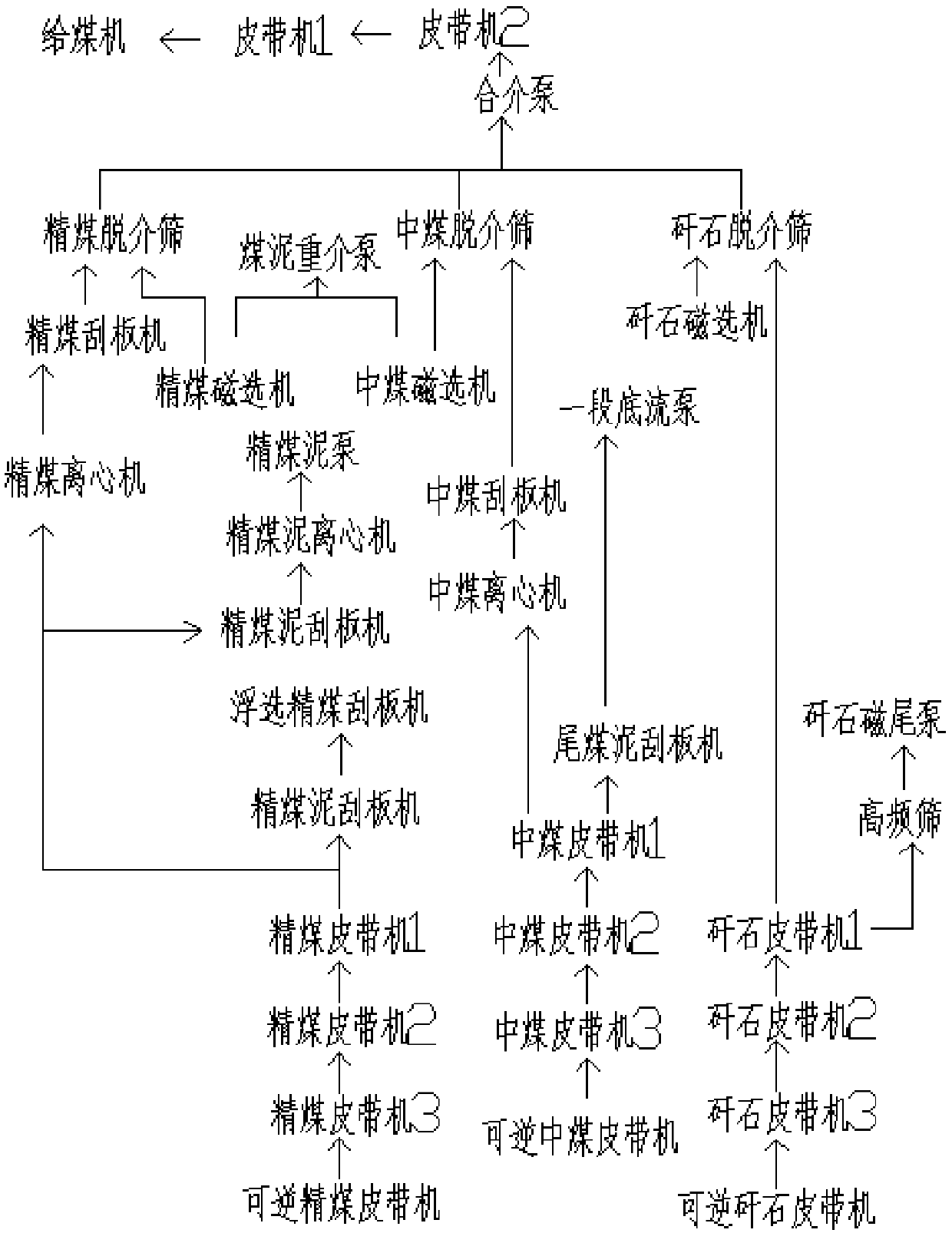

[0044] During the production process, when the downstream locking equipment fails to stop, the superior locking equipment must stop immediately, and all vibrating arc screens in the main coal washing production system do not participate in the locking shutdown, that is, the equipment of the main coal washing system forms a locking relationship. image 3 In the waste rock production process, the sequence from the downstream locking equipment to the upstream locking equipment is as follows: reversible gangue belt conveyor - gangue belt 3 - gangue belt 2 - gangue belt 1, and then divided into two paths, namely high frequency screen - gangue magnetic tail pump And the waste rock removal screen-combination pump-belt conveyor 2-belt conveyor 1-coal feeder; the sequence from the downstream locking equipment to the upstream locking equipment in the production process of China Coal is: reversible China Coal Belt Conveyor - China Coal Belt Machine 3—China Coal Belt Conveyor 2—China Coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com