Paper cutter bed guide mechanism

A technology of guiding mechanism and paper cutting machine, which is applied in metal processing and other directions, can solve the problems of material cost, high processing cost, affecting normal production, unusable linear guide rail pairs, etc., and achieves the reduction and adjustment of processing accuracy and smoothness requirements The eccentric angle is light and flexible, and the effect of prolonging the effective working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

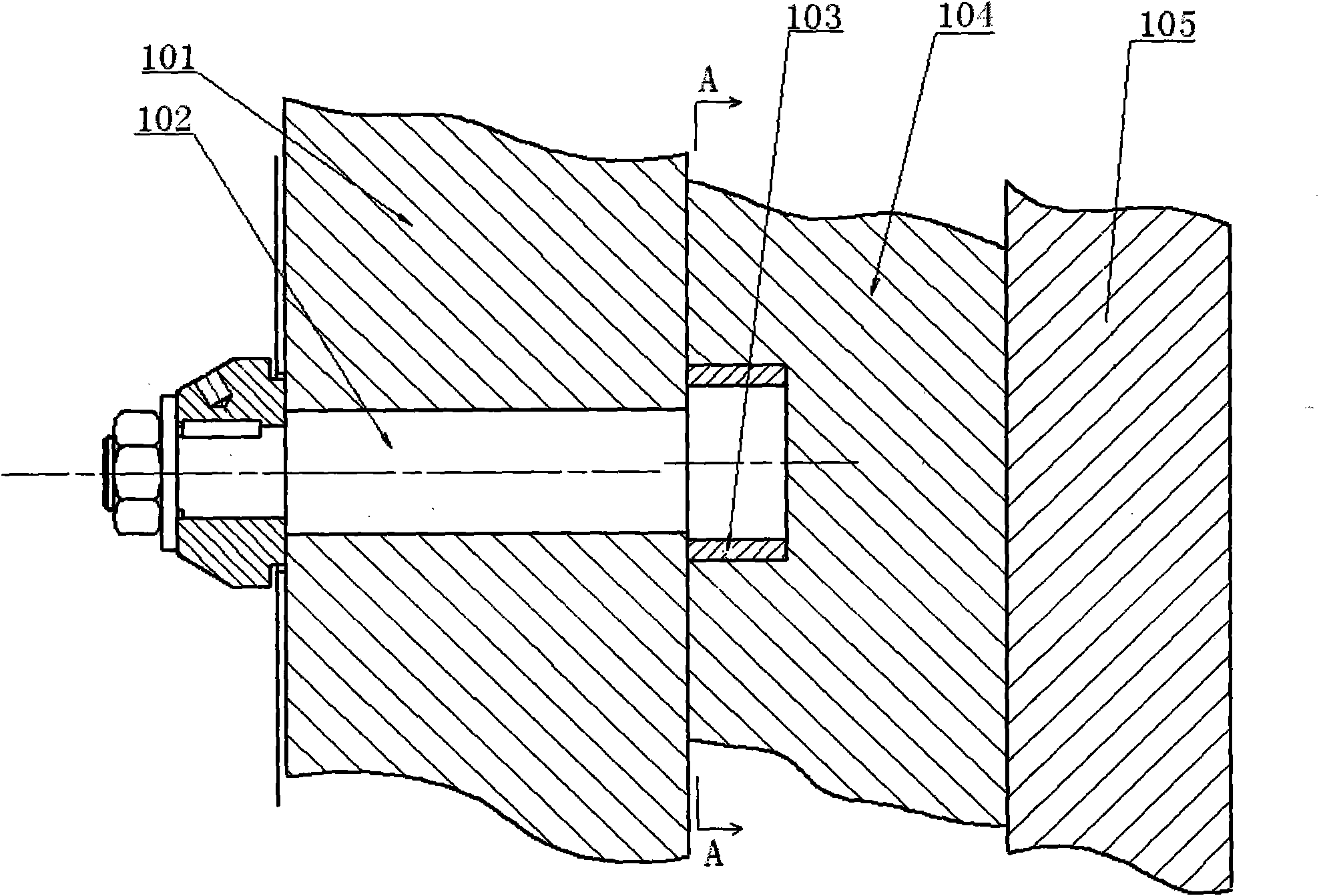

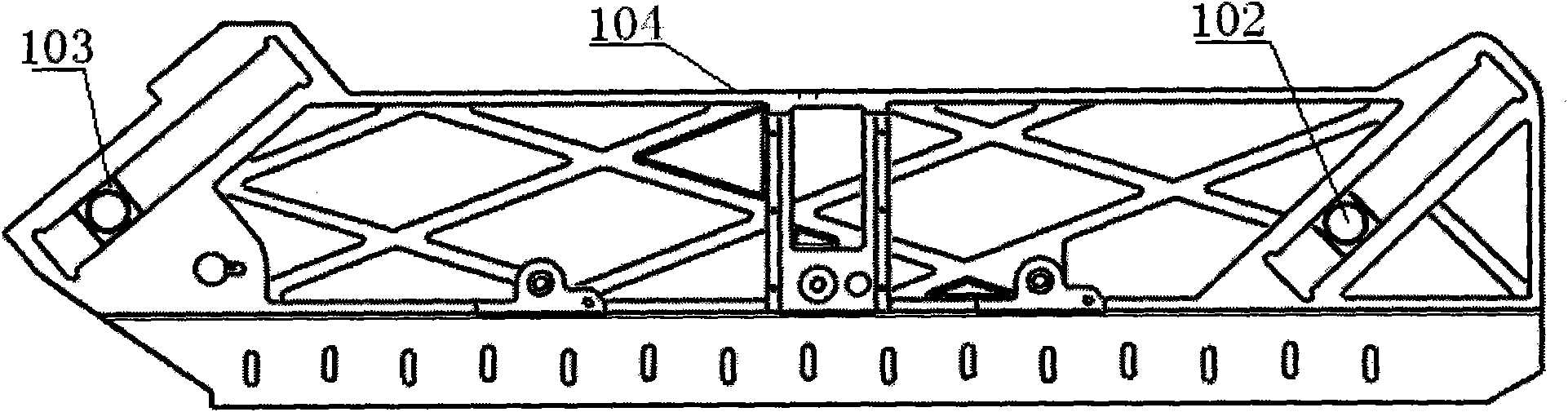

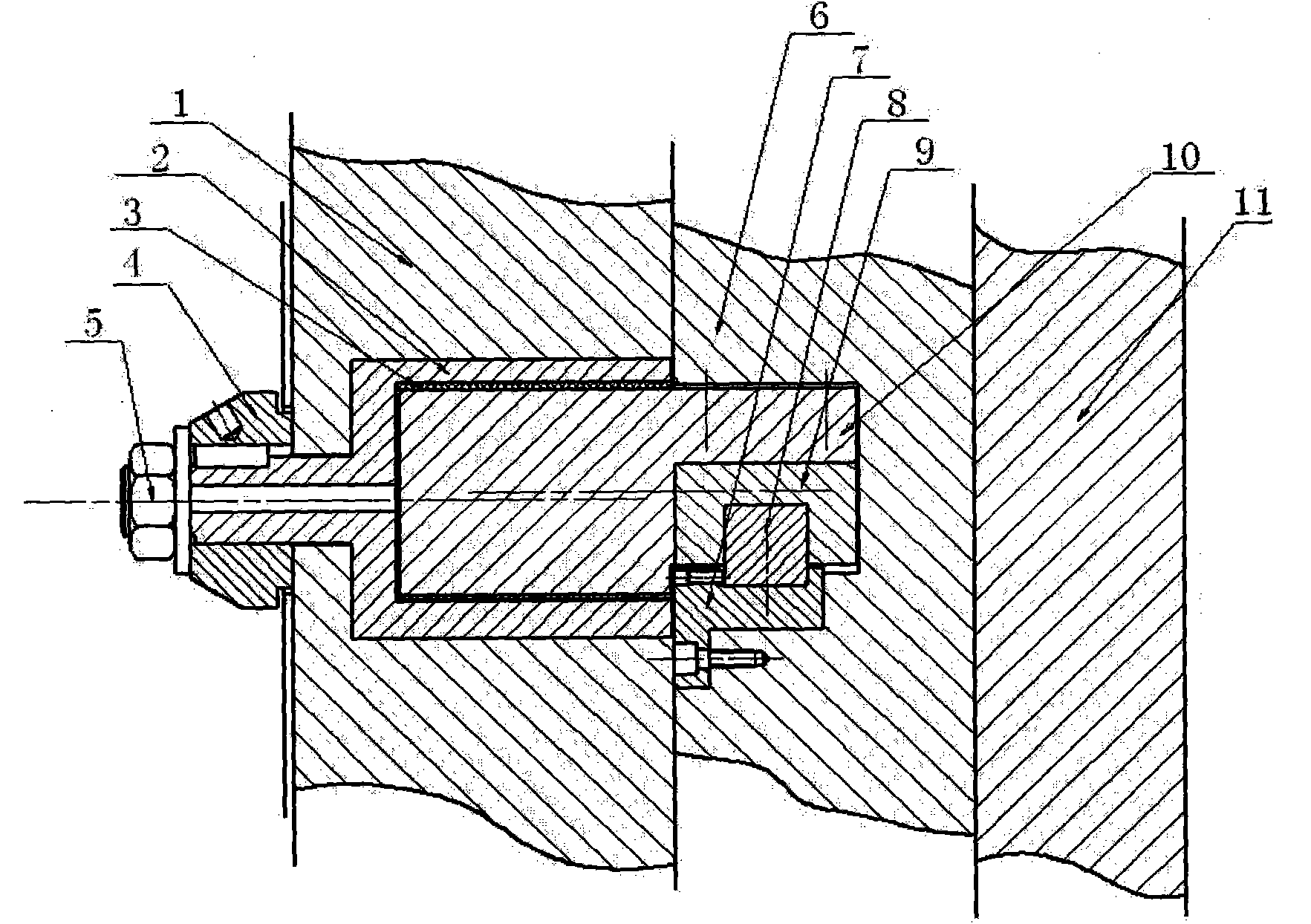

[0023] see image 3 The present invention comprises a main frame 1 and a sub-frame 11, a knife bed 6 is located between the main frame 1 and the sub-frame 11, and the two opposite surfaces of the knife bed 6 slide with the opposite faces of the main frame 1 and the sub-frame 11 respectively Cooperate.

[0024] There is a pair of assembly holes on the main frame 1, and the eccentric sleeves 2 are respectively installed in the holes. The eccentric sleeves 2 pass through the assembly holes on the main frame 1 and extend to the back of the main frame 1. An eccentric adjustment handwheel 4 that rotates synchronously with it is installed, and a nut 5 is arranged on the outside of the eccentric adjustment handwheel 4, and the eccentric sleeve 2 is locked and fixed in the assembly hole on the main frame 1 by the nut 5 . A connecting shaft 10 is housed in the eccentric sleeve 2, and the connecting shaft 10 is movably matched with the eccentric sleeve 2, and a bearing 3 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com