Timing control system and method for non-salient pole permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and control system, applied in control system, single motor speed/torque control, vector control system, etc., can solve problems such as increasing the hardware cost of drive control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

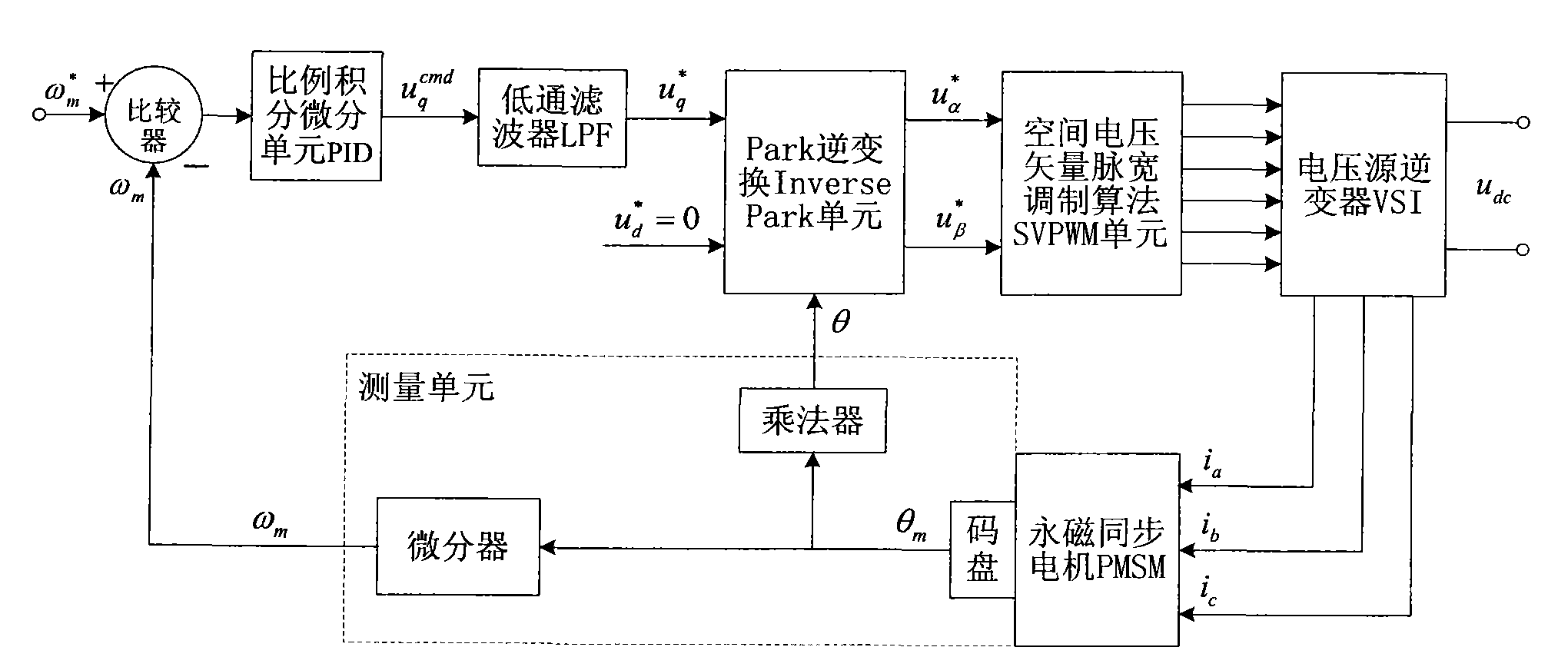

[0085] Embodiment 1, a speed regulation control system of a hidden pole type permanent magnet synchronous motor, such as figure 1 As shown, it includes: proportional integral differential unit PID, Park inverse transform Inverse Park unit, space voltage vector pulse width modulation algorithm SVPWM unit, voltage source inverter VSI, comparator, and measurement unit.

[0086] The measuring unit is used to measure the electrical angle position θ of the rotor of the hidden pole permanent magnet synchronous motor and the mechanical speed ω of the motor m .

[0087] In this embodiment, the measuring unit may include:

[0088] Position measurer, multiplier and differentiator.

[0089] The position measuring device is used to measure the mechanical angular position θ of the rotor m , respectively sent to the multiplier and differentiator; in this embodiment, the position measuring device can be, but not limited to, a code disc installed on the motor shaft end of the hidden pole pe...

Embodiment 2

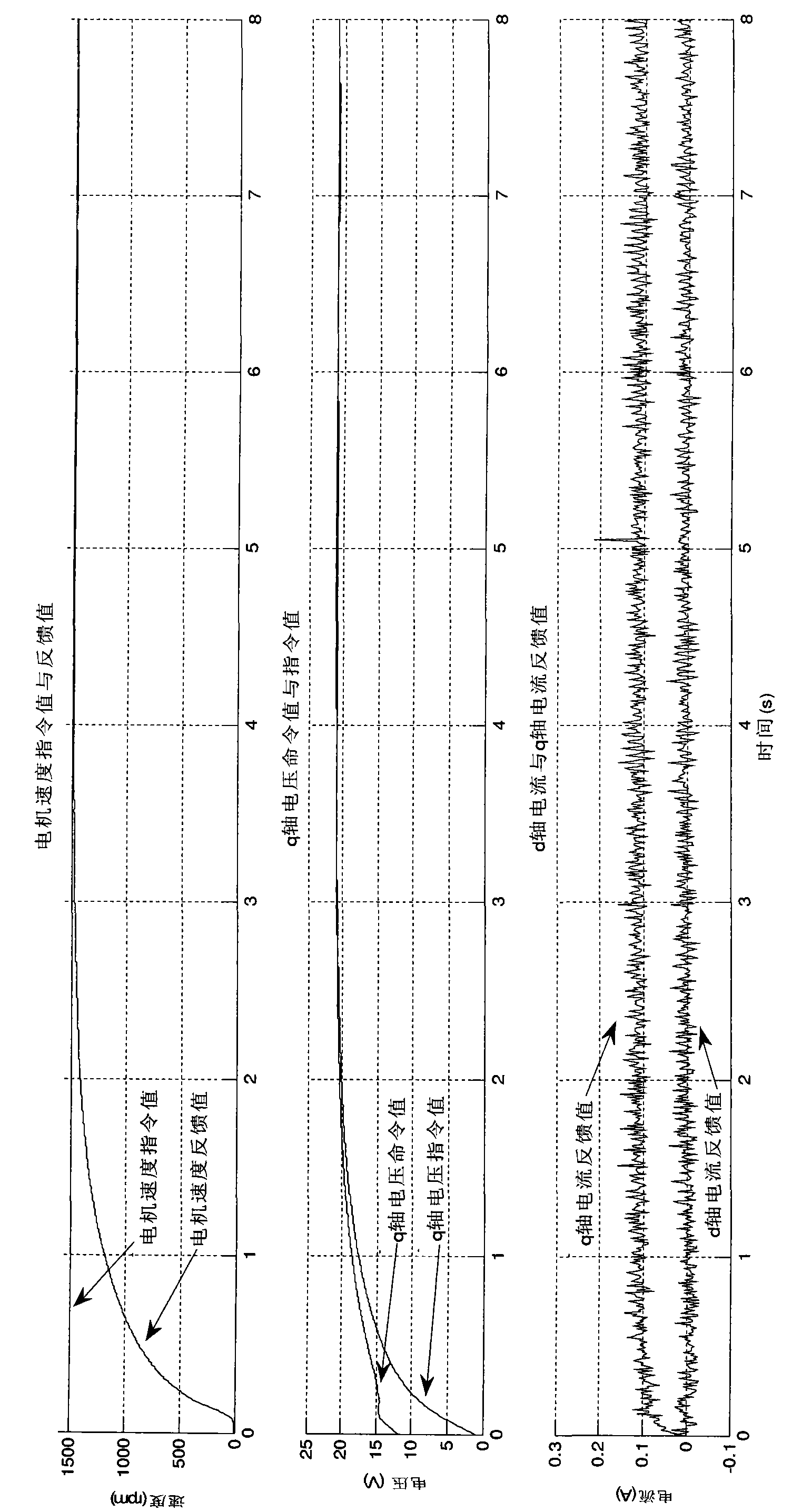

[0107] Embodiment 2, a speed regulation control method of a hidden pole permanent magnet synchronous motor, comprising:

[0108] Measure the electrical angle position θ of the rotor of the hidden pole permanent magnet synchronous motor and the mechanical speed ω of the motor m ;

[0109] Get the preset target speed ω m * and ω m the difference;

[0110] Perform proportional, integral, and differential operations on the difference to obtain the q-axis voltage component command value u q * ;

[0111] According to θ for u d * and the u q * Perform PARK inverse transformation to obtain the voltage vector u on the stationary coordinate system α * and u β * ; Among them, the u d * is 0;

[0112] According to the voltage vector u α * and u β * , using the space voltage vector pulse width modulation algorithm to generate the pulse width signal of the power device;

[0113] Generate three-phase winding current i according to the pulse width signal of the power dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

| Damping coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com