Patents

Literature

53results about How to "Shock absorber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

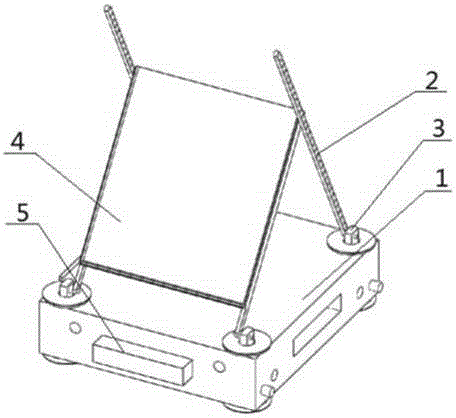

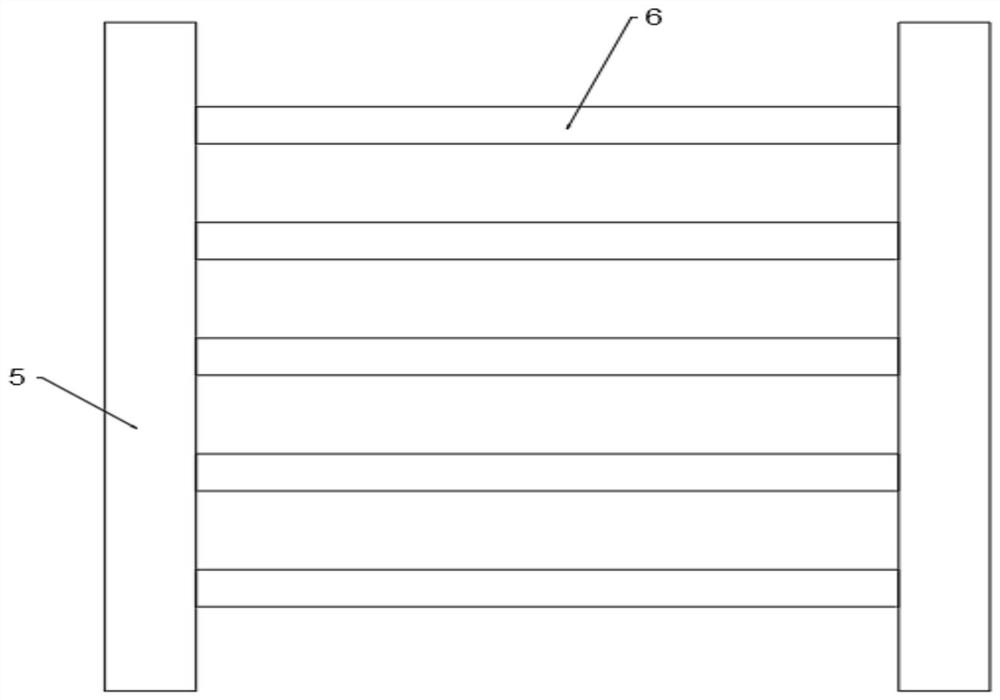

Floating member used for waterborne photovoltaic power station and connection method thereof

InactiveCN105186968ASimplify the installation processImprove stabilityPV power plantsPhotovoltaic energy generationPhotovoltaic power stationSurface level

The invention discloses a floating member used for a waterborne photovoltaic power station and a connection method thereof. The floating member at least comprises a floating member body which can be floated on water. The floating member body comprises a first end part and a second end part. Height of the upper surface of the first end part is lower than that of the upper surface of the second end part. The upper surface of the floating member body, which is close to the first end part, is provided with a first connection structure which is used for being detachably connected with the first connection piece of the back surface of a photovoltaic panel. The upper surface of the floating member body, which is close to the second end part, is provided with a second connection structure which is used for being detachably connected with the second connection piece of the back surface of the photovoltaic panel. Height of the upper surface of the first end part of the floating member body is set to be higher than that of the upper surface of the second end part, and the connection structures connected with the photovoltaic panel are directly arranged on the upper surface of the floating member body so that the installing technology of the photovoltaic power station can be greatly simplified, installing time can be saved and installing cost can be reduced.

Owner:SHANGHAI QIHUA WHARF ENG CO LTD

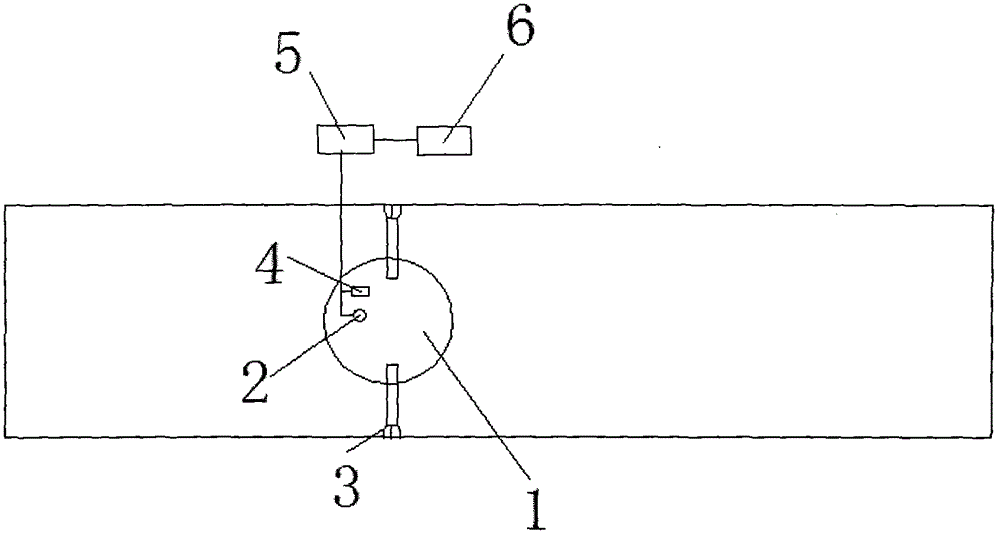

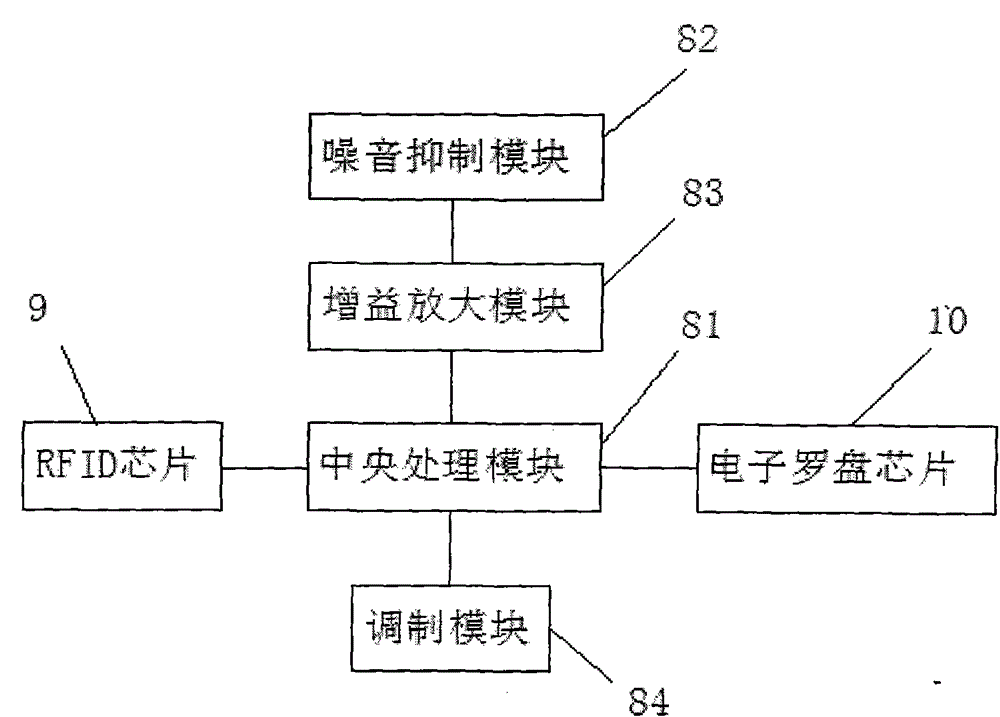

Positioning device for pipeline blockage points

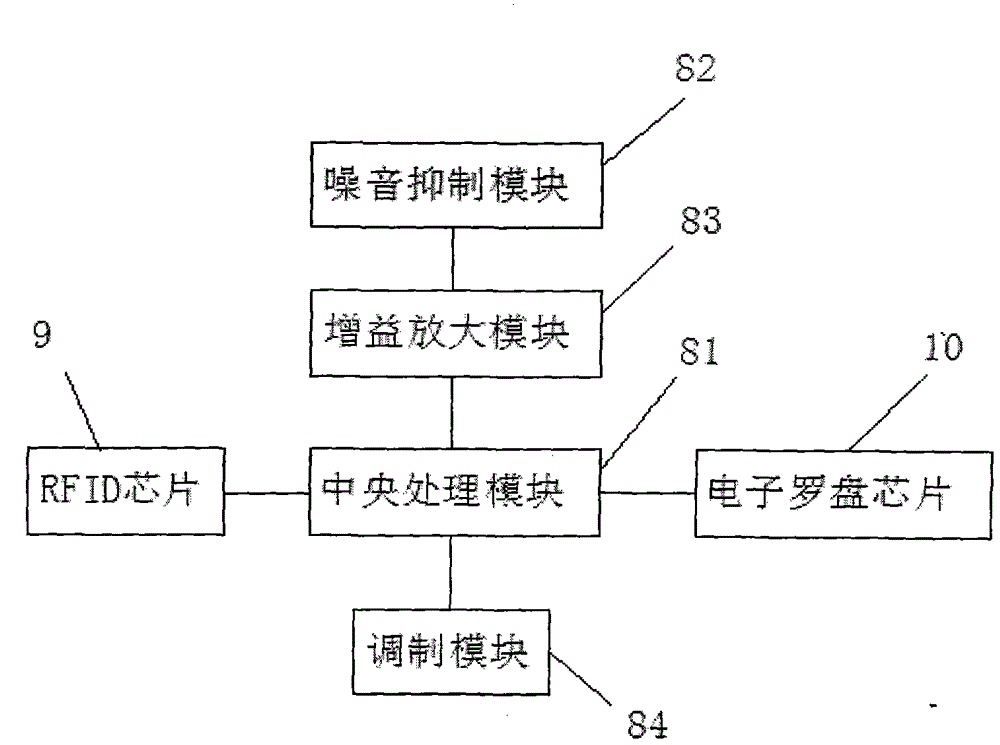

InactiveCN104613320AReduce layoutShock absorberPipeline systemsSatellite radio beaconingDisplay devicePigging

The invention discloses a positioning device for pipeline blockage points. The positioning device for the pipeline blockage points comprises a spherical pig, a GPS positioner, an elastic storage type claw, a fiber optic sensor, a signal collection device and a computer display device. The GPS positioner and the fiber optic sensor are arranged on the spherical pig, the elastic storage type claw is arranged in a hole in the spherical pig, the fiber optic sensor is connected with the computer display device through the signal collection device, the inner end of the elastic storage type claw is connected with the inner wall of the spherical pig through a spring, the outer end of the elastic storage type claw is locked with the outer wall of the spherical pig through a buckle, the GPS positioner comprises a shell, and a GPS chip, a RFID chip, an electronic compass chip, a control circuit board and a lithium battery are arranged in the shell. The positioning device for the pipeline blockage points is simple in structure, convenient to use, reliable in use, accurate in positioning and strong in practicability, and capable of positioning in time and performing breakover.

Owner:XIAN UNIV OF SCI & TECH

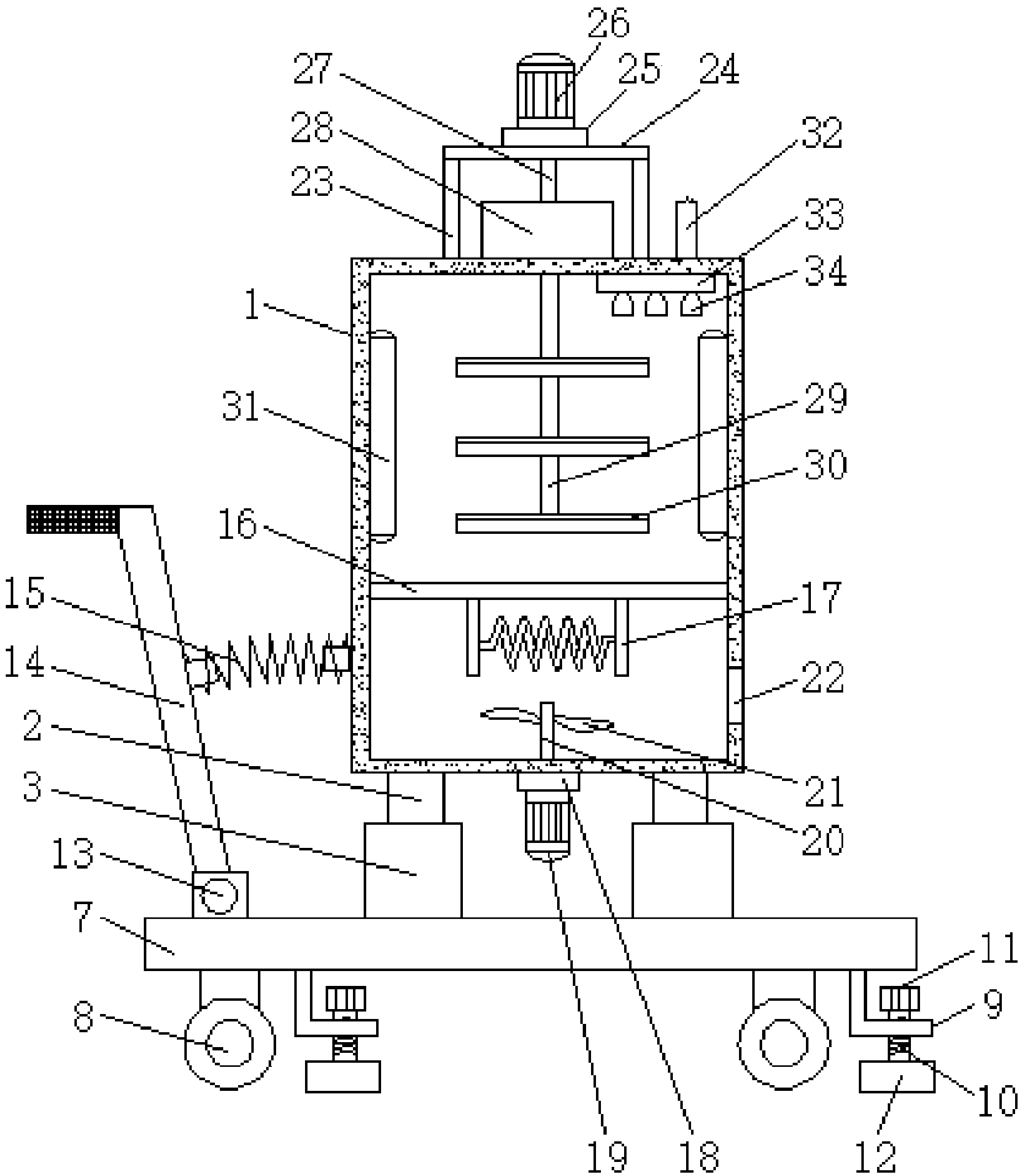

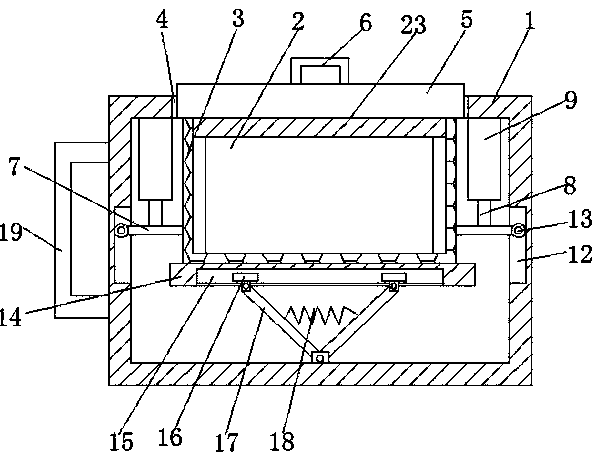

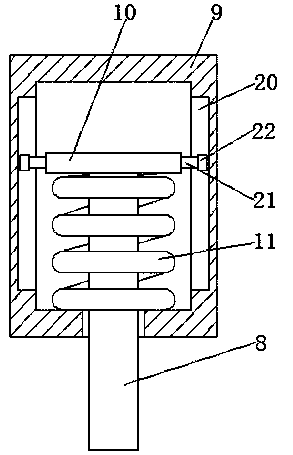

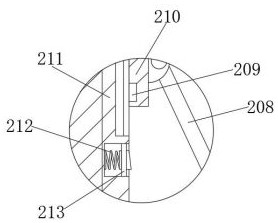

Medical sterilization box

InactiveCN107773771AUniform irradiation sterilizationImprove the bactericidal effectLavatory sanitoryHeatMotor driveEngineering

The invention provides a medical sterilization box and relates to the field of medical tools. The medical sterilization box comprises a box body, wherein four corners of the bottom of the box body arefixedly connected with the top end of a pressing rod; the bottom end of the pressing rod penetrates through a shock absorber and extends into the shock absorber to be fixedly connected with the top of a pressing block; hydraulic oil is arranged in the shock absorber and at the bottom of the pressing block; and the bottom of the shock absorber is fixedly connected with the top of a supporting plate. According to the medical sterilization box provided by the invention, a second motor is arranged at the top of the box body and a speed regulation device is arranged; meanwhile, a second output shaft and trays which uniformly sleeve on the surface of the second output shaft are arranged, and ultraviolet sterilization lamps are arranged at the left and right sides in the box body, so that the second motor drives the speed regulation device to move and the second output shaft drives the trays to rotate at a constant speed; and therefore, objects at the tops of the trays are conveniently and uniformly irradiated and sterilized, the sterilization effect is greatly improved and the efficiency is high.

Owner:新昌县佳良制冷配件厂

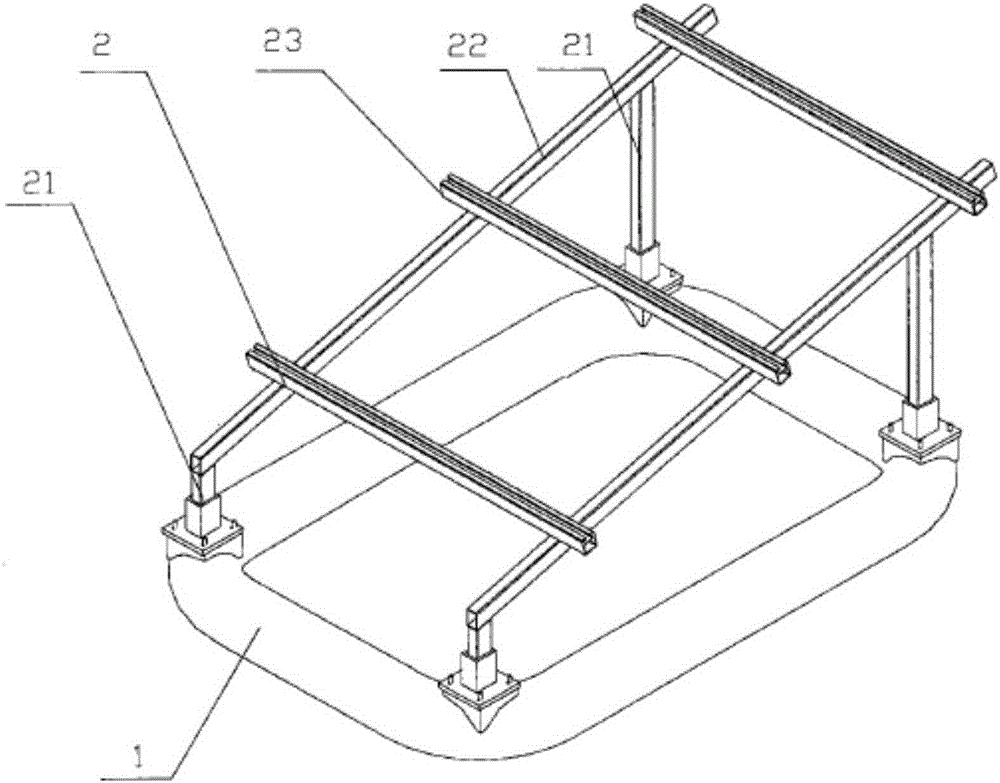

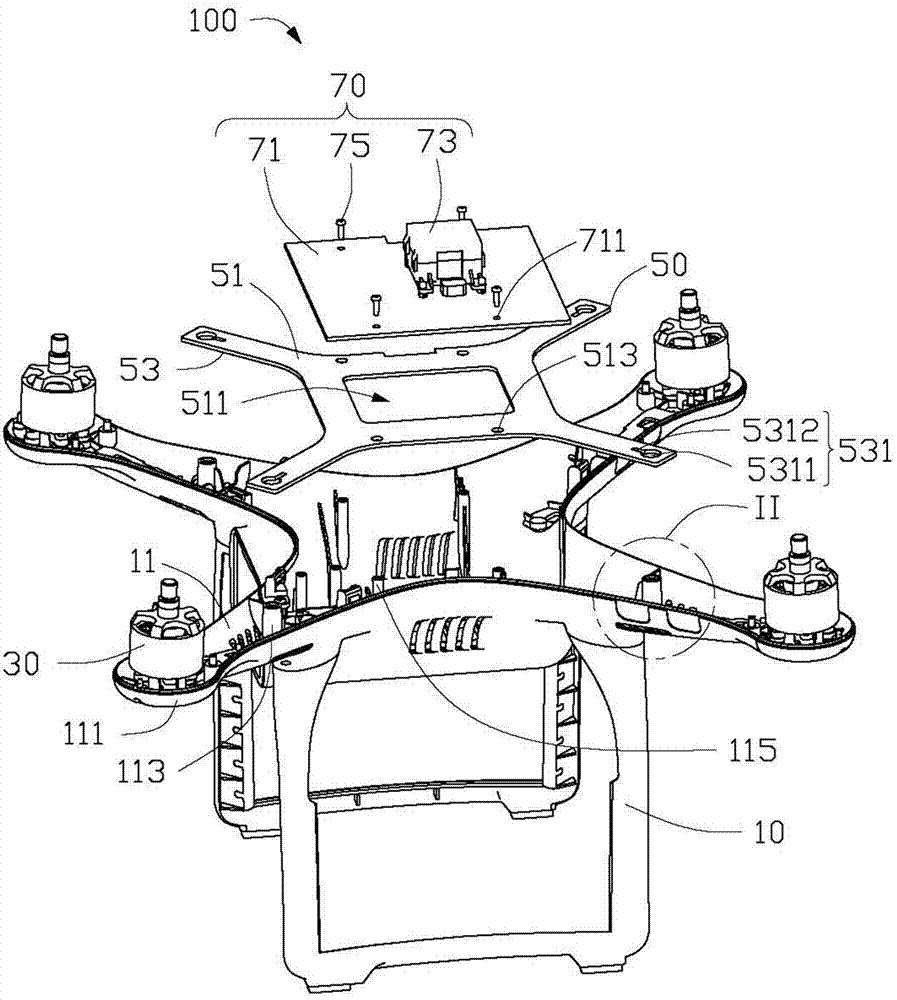

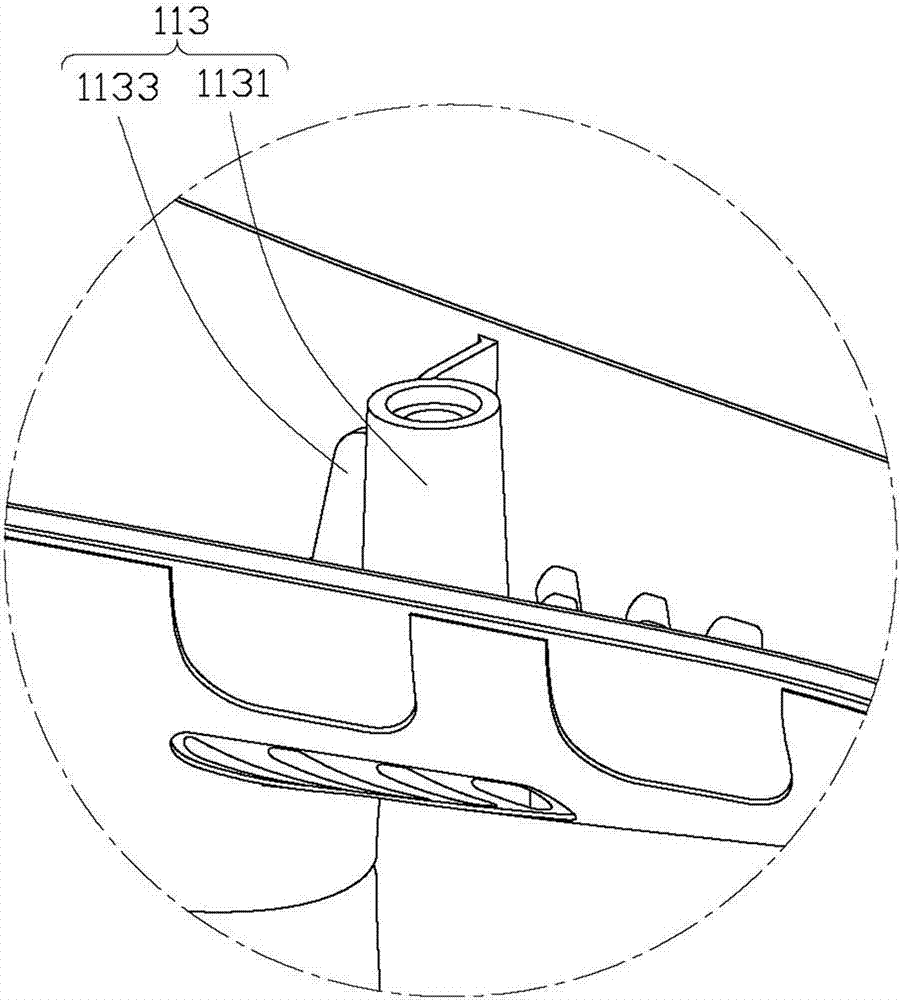

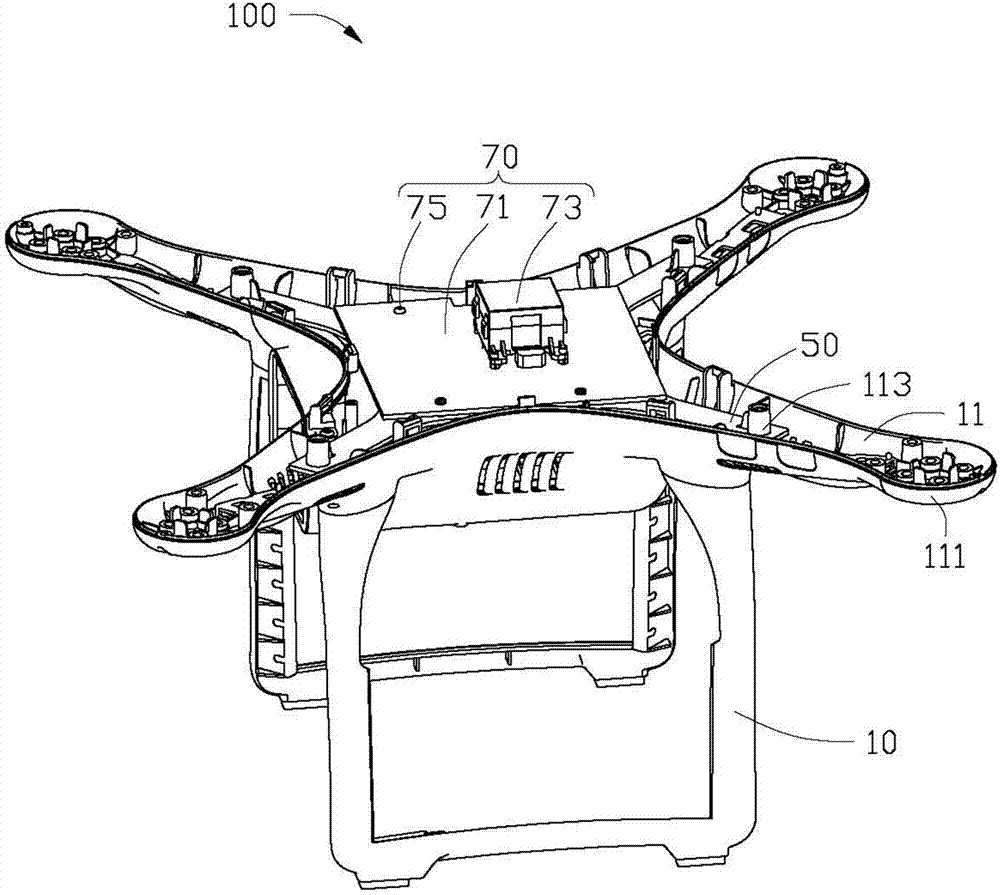

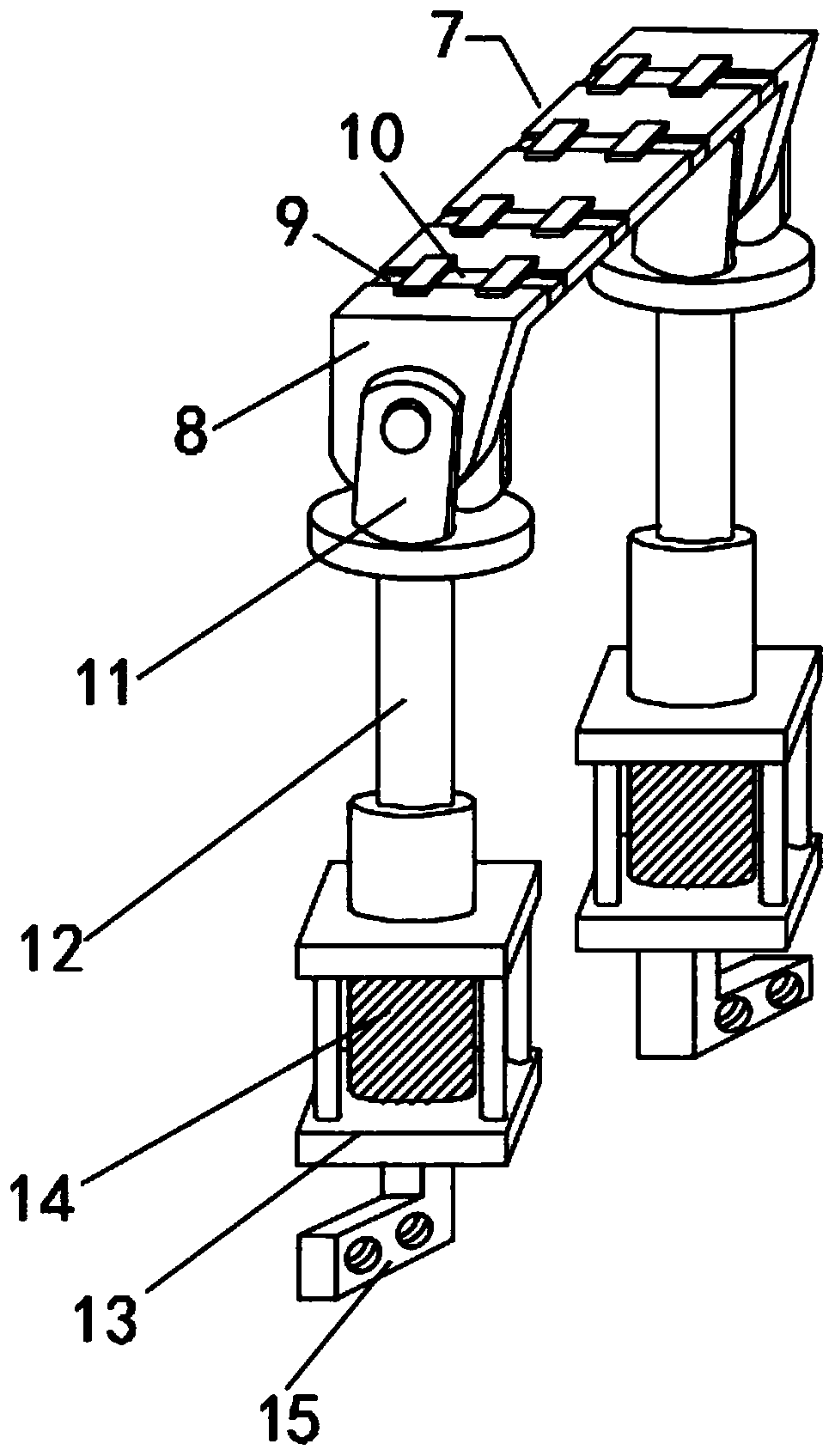

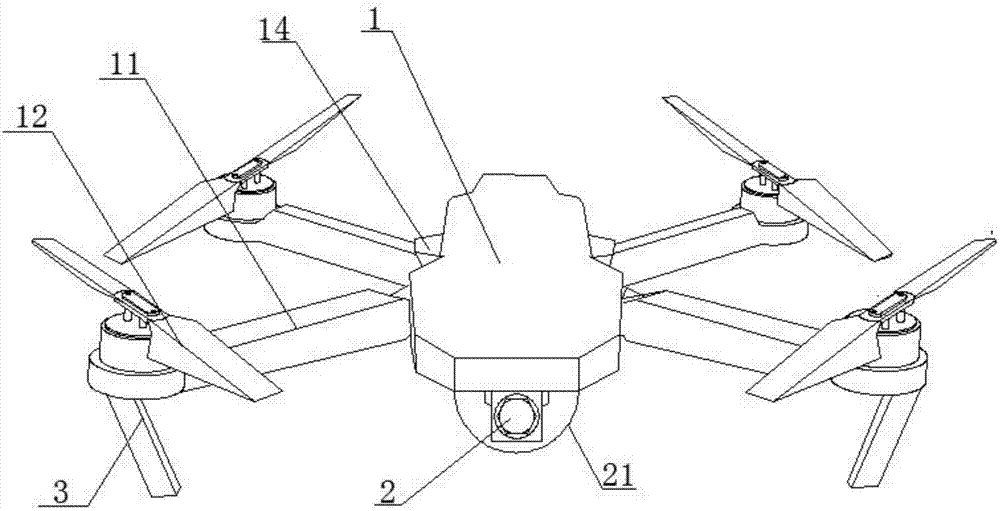

Damping bracket and flight equipment applying same

ActiveCN104776141AImprove institutional strengthReduce deformationAircraft componentsShock absorbersMarine engineeringCantilever

The invention relates to a damping bracket and flight equipment applying the same. The flight equipment comprises a fuselage, a sensing module and the damping bracket; the fuselage comprises at least one branch cantilever and at least one fixed part correspondingly arranged at the position of the branch cantilever; the damping bracket comprises a main body part and at least one extending part formed by extending from the main body part; the main body part is used for bearing an object; the extending part is used as a fixed position; the extending part of the damping bracket is connected with the corresponding fixed part; the sensing module is connected to the fuselage through the damping bracket. According to the flight equipment, intensity of the flight equipment is reinforced by the damping bracket and the aims of damping and resisting to vibration are fulfilled.

Owner:SZ DJI TECH CO LTD

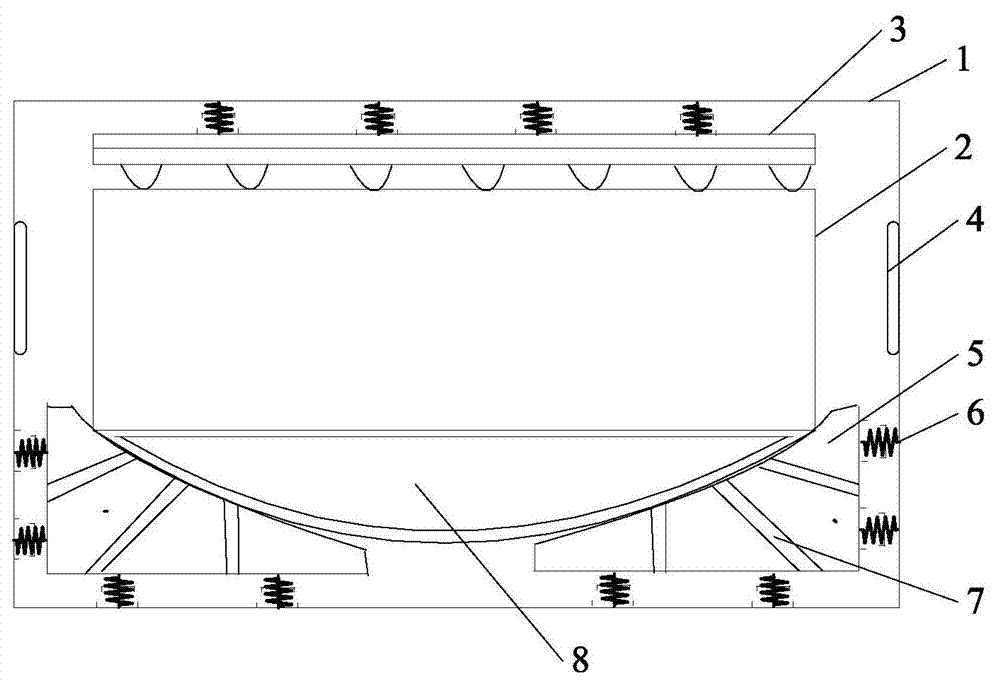

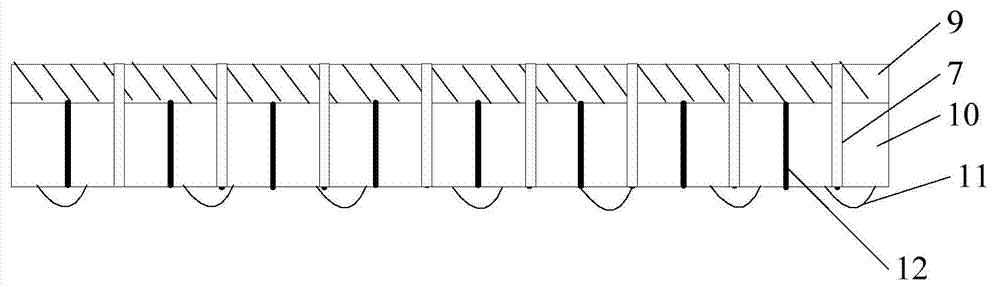

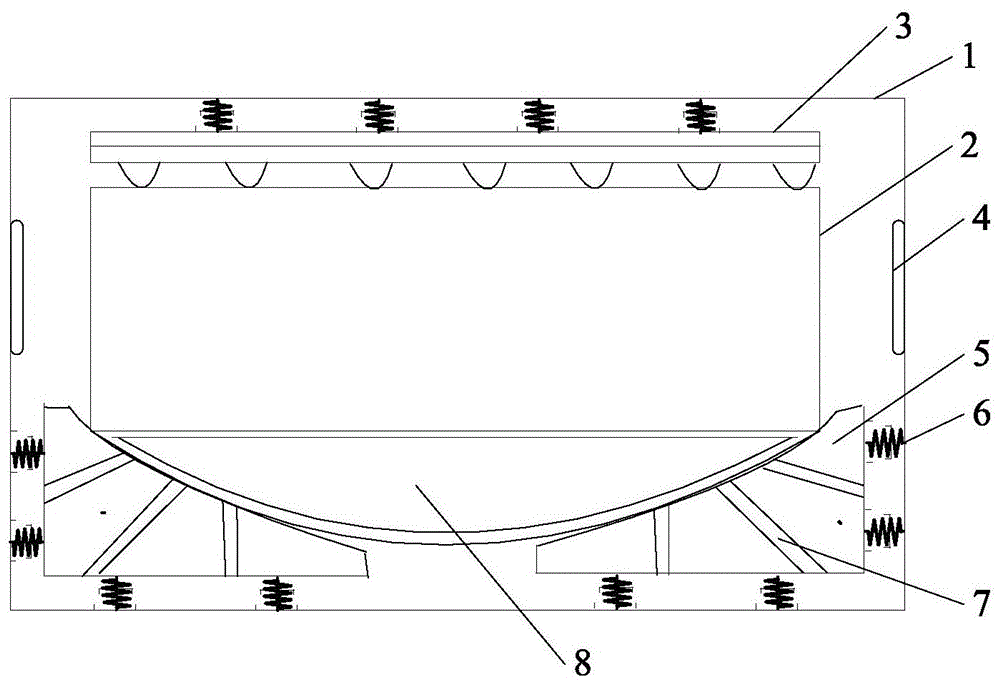

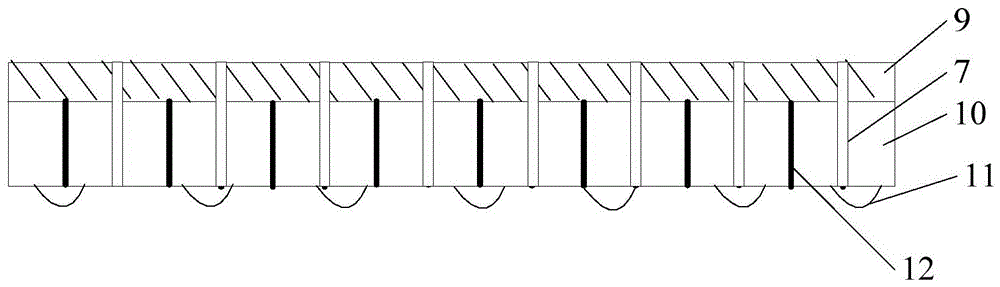

Hard disk video with vibration isolation equipment

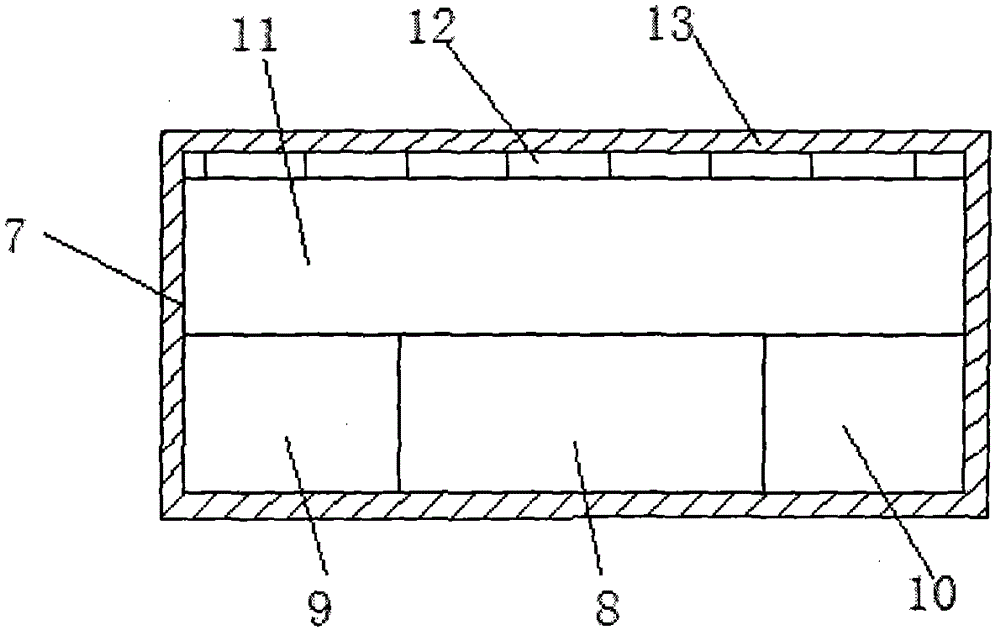

ActiveCN103945155AIncrease elasticityGently eliminate vibrationTelevision system detailsUndesired vibrations/sounds insulation/absorptionCooling effectVibration isolation

The invention discloses a hard disk video with vibration isolation equipment. The hard disk video comprises a hard disk body, a shell and vibration isolation equipment, wherein the hard disk body is arranged in a hard disk holding cavity in a hard disk video case, the shell is arranged in the hard disk holding cavity so as to enclose the hard disk body, and the isolation equipment is arranged in the shell; the damping device comprises an upper end damping part and a lower end damping part, wherein the upper end damping part is a rectangular structural body and is respectively divided into a solid layer, a hollow layer and a raised layer from top to bottom, and the thickness proportion of the solid layer, the hollow layer and the raised layer is (1-2): (2-4): 1; the lower end damping part comprises two wedged structural bodies which are alternately arranged at the bottom of the hard disc body, and the axial directions of the wedge structural bodies and the axial direction of the hard disc body are arranged in parallel. The hard disk video with the vibration isolation equipment is simple in structure, good in vibration isolation effect, good in cooling effect and convenient to change a hard disk, so that the hard disk video can be applied to mass production.

Owner:哈威光电科技(苏州)有限公司

Echometer placing box

InactiveCN108836492AShock absorberEasy to operateSurgical furnitureStethoscopeDamping functionEngineering

The invention discloses an echometer placing box. The echometer placing box comprises a box body and an echometer body; a placing chamber is arranged in an inner cavity of the box body; a hole openingis formed at the top of the box body; a box cover is arranged at the top of the placing chamber; the top of the box cover passes through the hole opening and extends to the outside of the box body; one side, positioned out of the box body, of the box cover is fixedly connected with a handle; the two sides of the placing chambers are fixedly connected with first sliding rods; the tops of the firstsliding rods are fixedly connected with damping rods. Through cooperative use of the first sliding rods, the damping rods, a damping chamber, a cross rod, a first spring, a first sliding groove, a pulley, a transverse plate, a second sliding groove and a first sliding block, the problem that the conventional placing box does not have a damping function is solved; the echometer placing box has theadvantage of damping, has good damping effect and high usability, is convenient to carry, can avoid breakage, is favorable for people to use and is worthy of popularization and use.

Owner:张俊铭

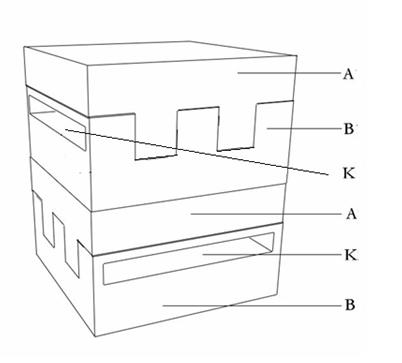

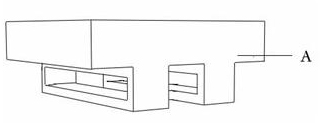

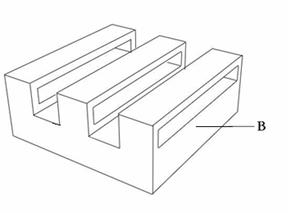

Damping seismic isolation and reduction device for building

The invention discloses a damping seismic isolation and reduction device for building, which is characterized by comprising two seismic isolation units which are vertically overlaid with each other, wherein each isolation unit is combined by an A part and a B part, contact surfaces of the A and the B parts are provided with one or more guide rails and chutes which are relative concavely and convexly, the side surfaces of the chutes vertical to the sliding direction of the guide rails are provided with one or more elongated openings, a metal bar rubber block is inserted in each elongated opening, and the two ends of the metal bar rubber block are provided with steel bars. Acting force of seismic wave horizontal components to the buildings provided with the damping seismic isolation and reduction device can be reduced and isolated under this precondition that the buildings on the upper portions and the foundations can be effectively connected, thereby being capable of more securely achieving no collapsing in large earthquakes and no damage in middle earthquakes. Because the maximum displacement of the damping seismic isolation and reduction device is limited by a steel structure, rubber elastic materials and the like can not be acted by tension and shear, the problem that the buildings and the foundations are cut off caused by rubber fracture does not exist, and the damping seismic isolation and reduction device is safer in itself.

Owner:云南省地震局

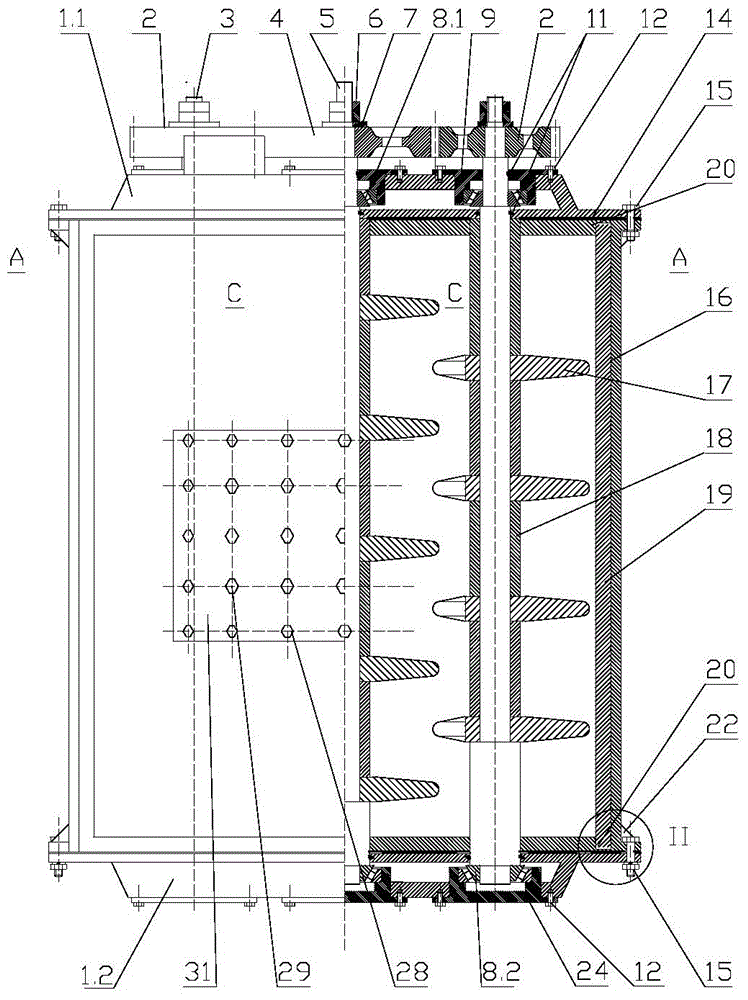

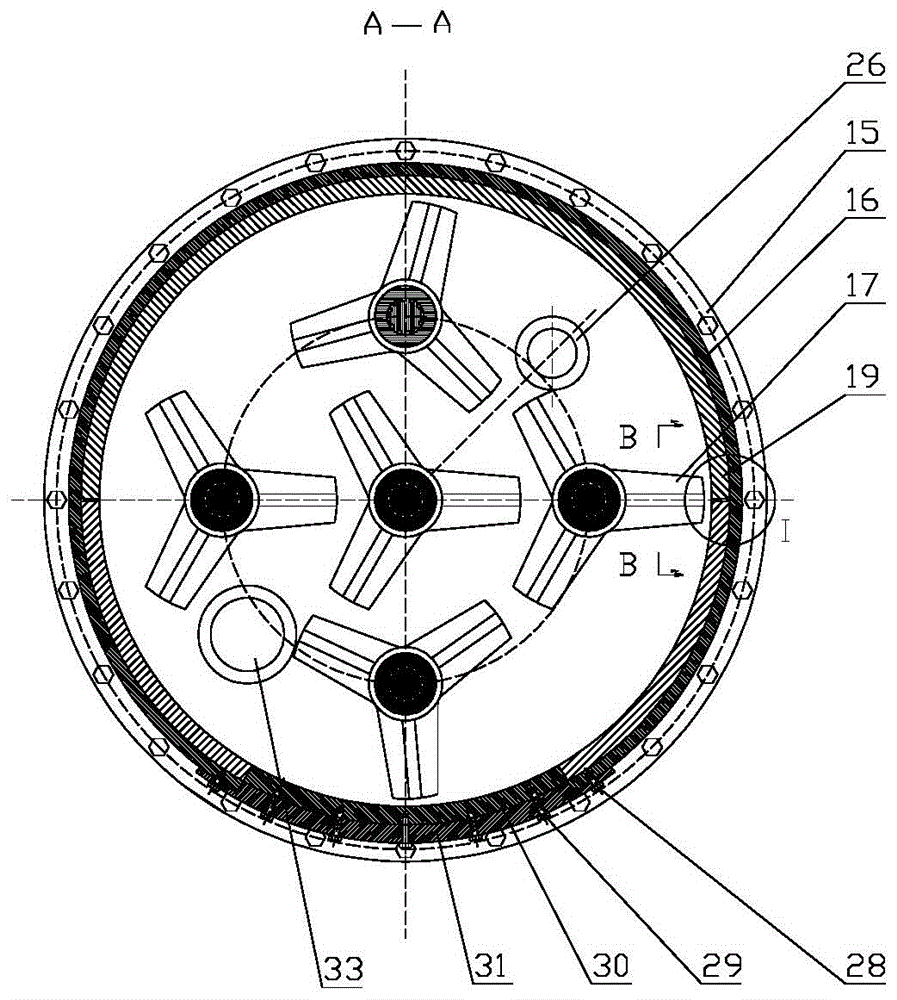

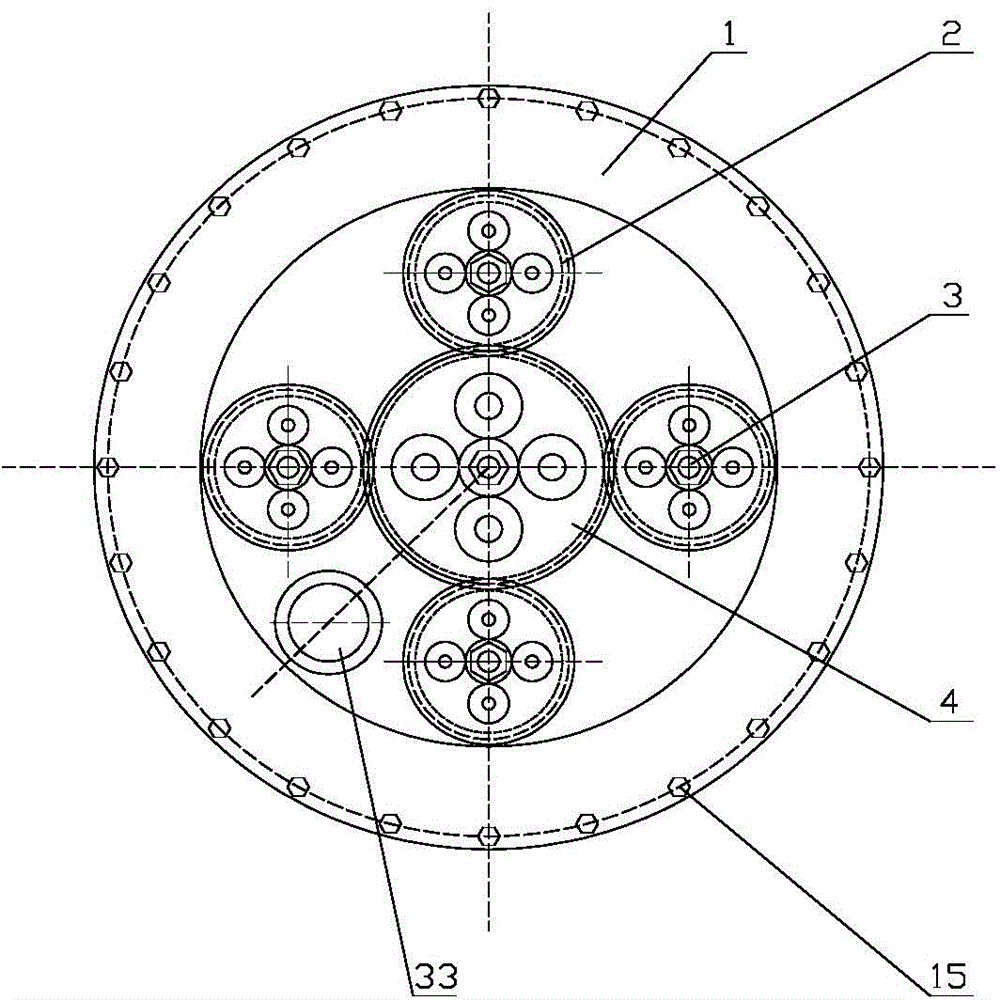

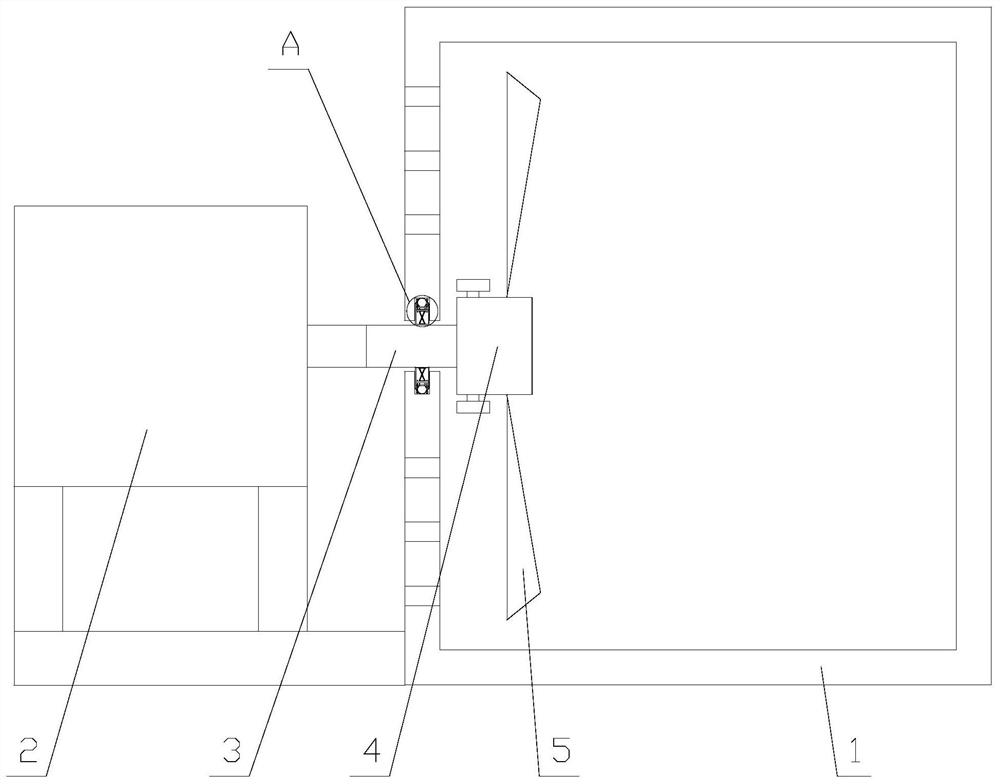

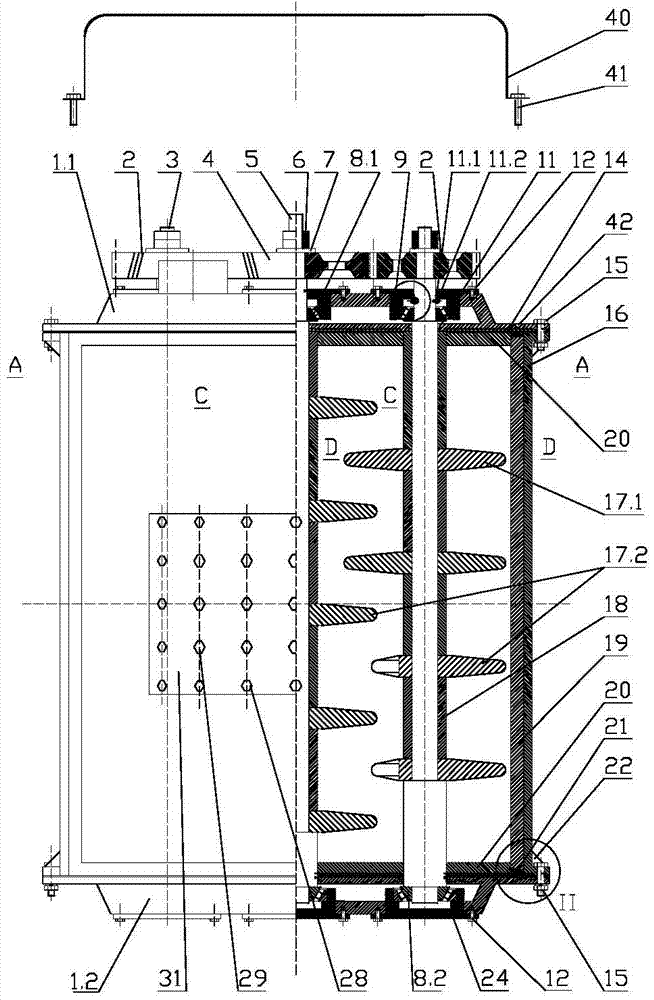

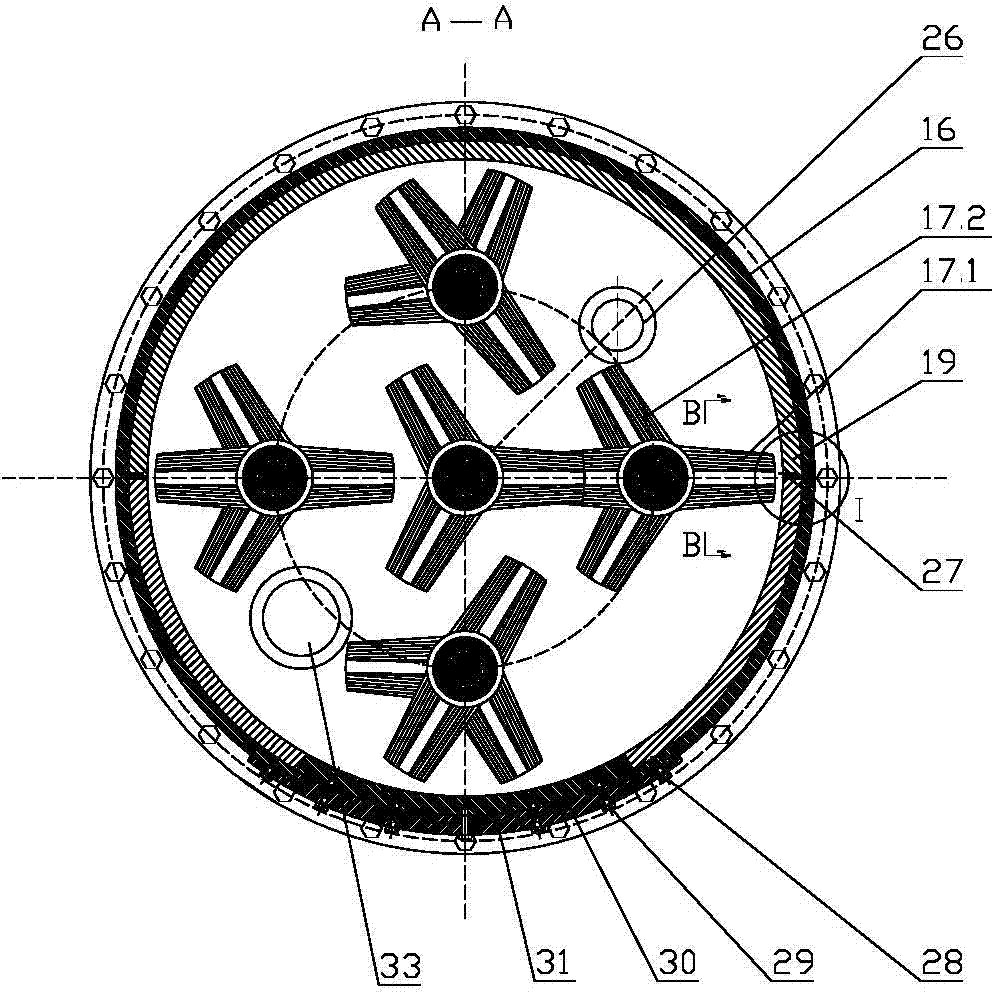

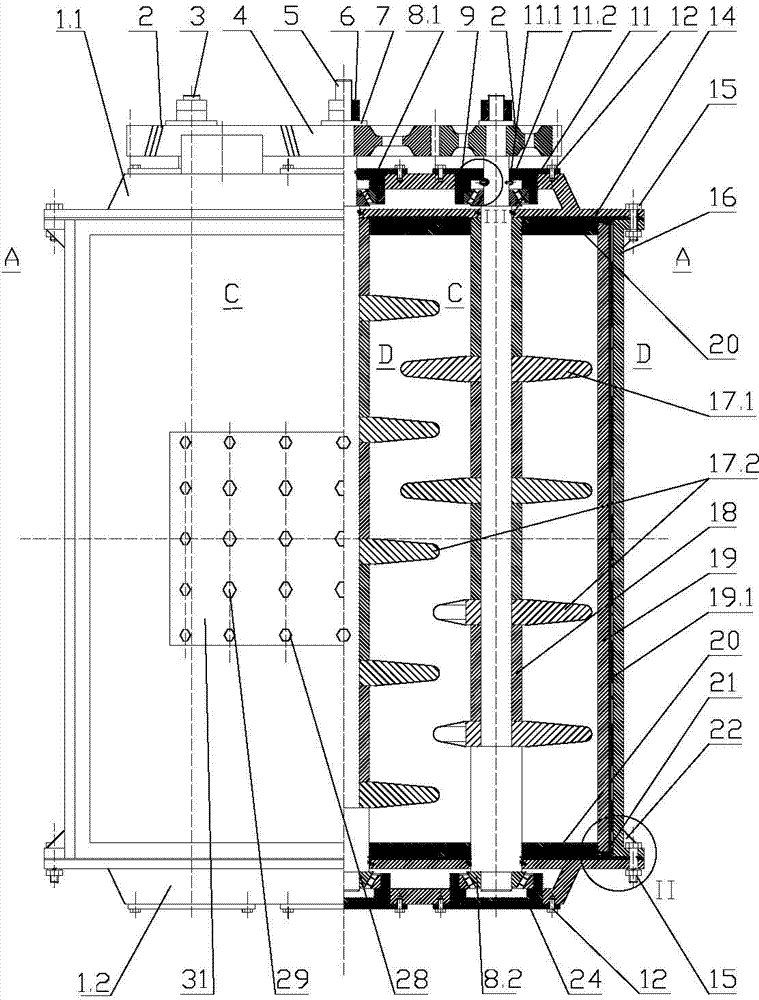

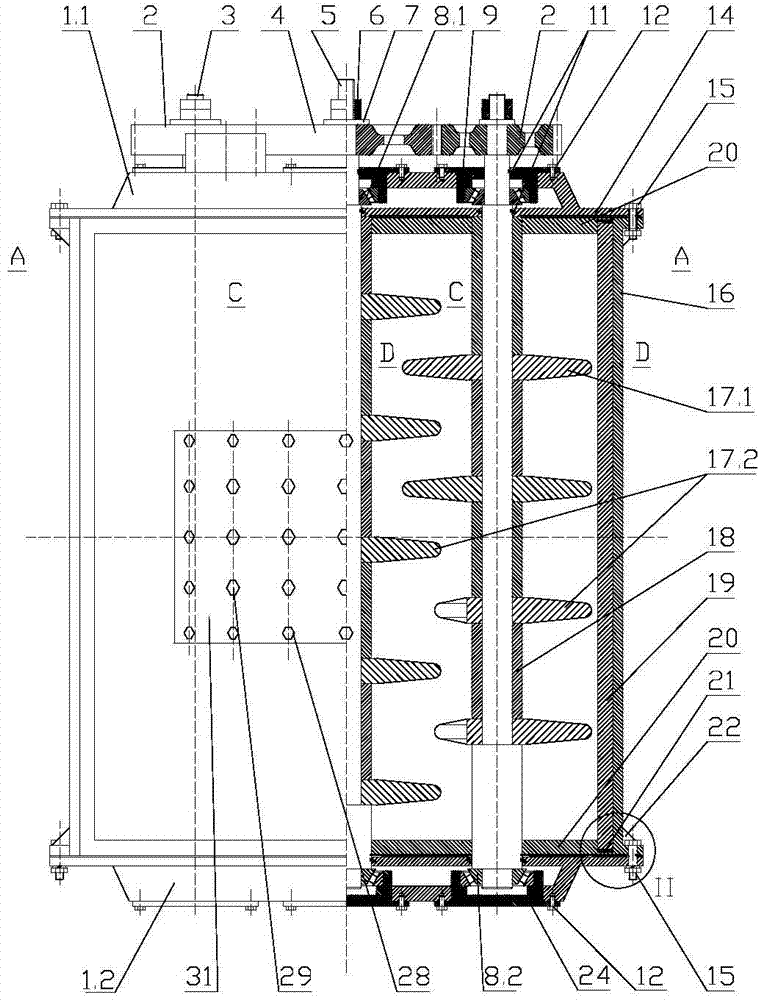

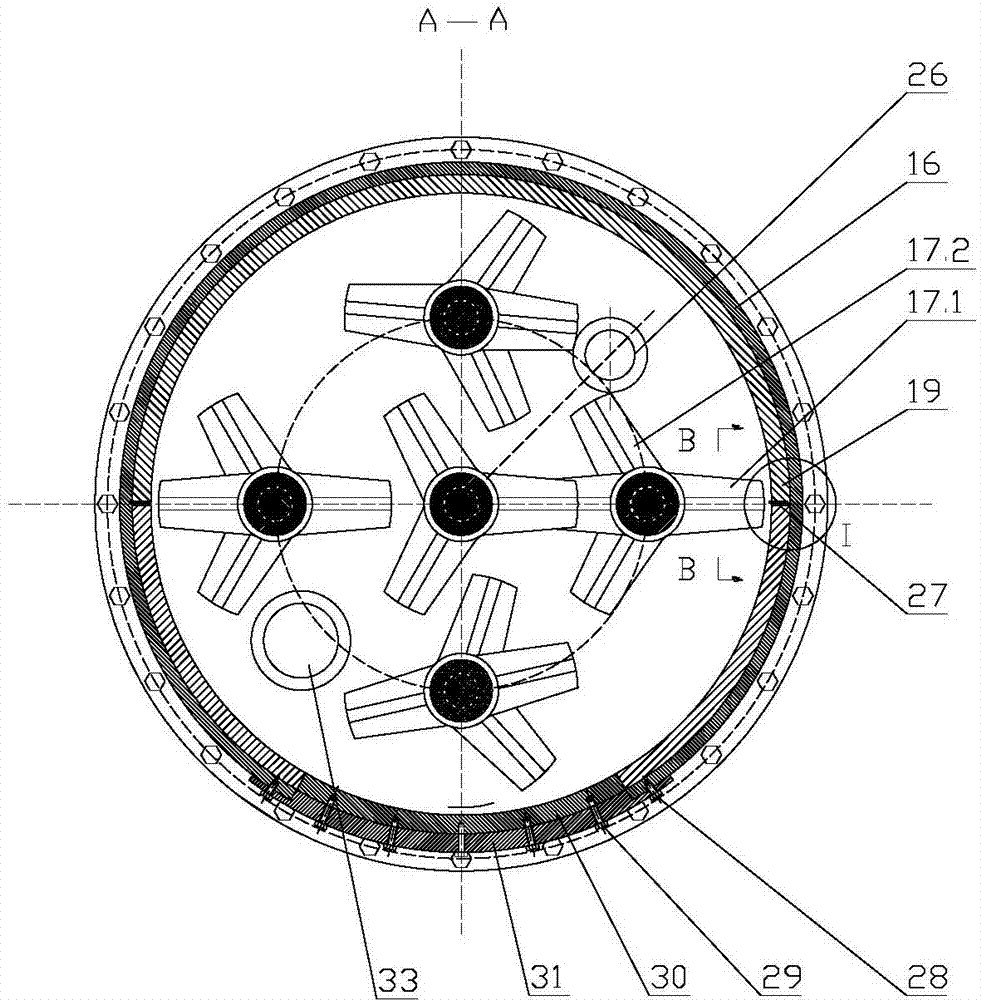

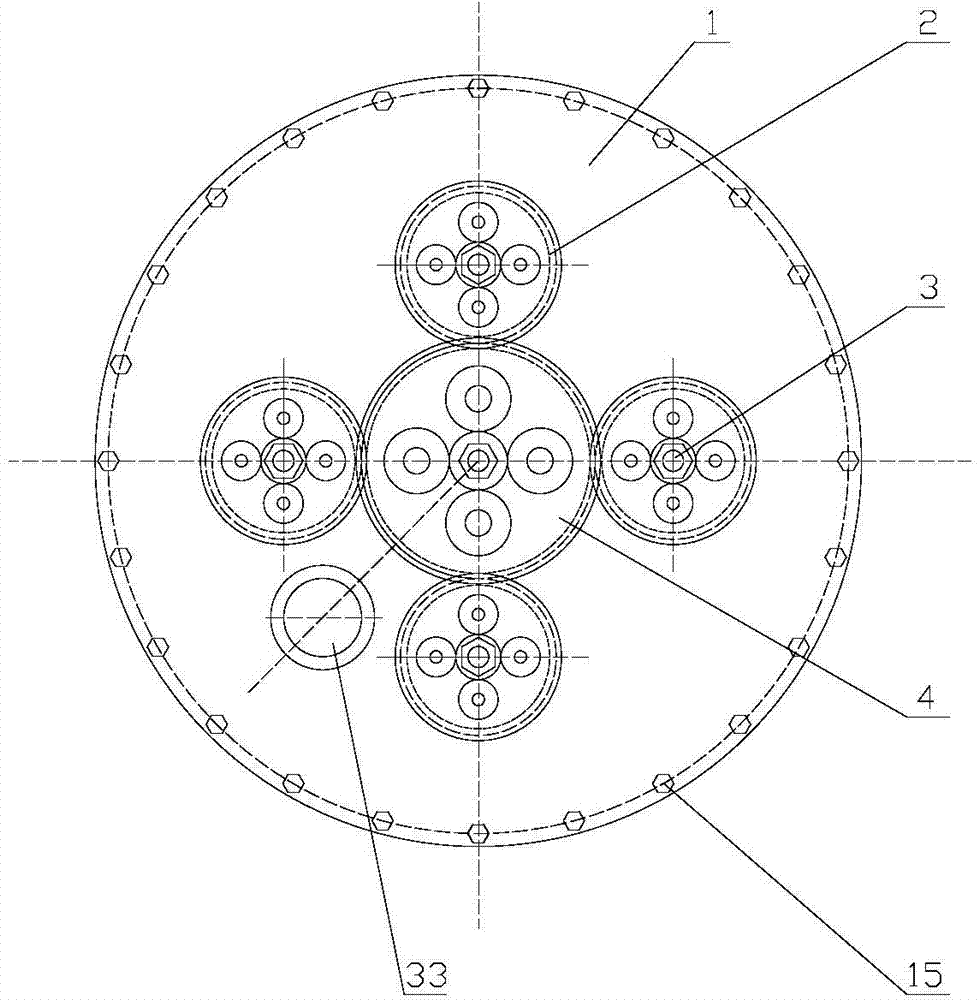

Buffer damping noise-reduction pulverizer

InactiveCN104826698AReduce energy consumptionImprove work efficiencyGrain treatmentsChinese charactersDrive shaft

The invention discloses a buffer damping noise-reduction pulverizer. The buffer damping noise-reduction pulverizer relates to the technical field of ore crushing machinery. The buffer damping noise-reduction pulverizer is characterized in that a pulverizer cylindrical shell is a columniform cylinder, the upper part of the pulverizer cylindrical shell is provided with an upper bearing box, the lower part of the pulverizer cylindrical shell is provided with a lower bearing box, the upper bearing box is connected to a bearing base ventilation cover, the lower bearing box is connected to a bearing base seal cover, an upper tapered roller bearing is installed in the upper and lower bearing boxes, a driving transmission shaft and a driven transmission shaft respectively are transmission shafts of a driving gear and a driven gear, the driving transmission shaft and the driven transmission shaft go through the bearing base ventilation cover, middles of the driving transmission shaft and the driven transmission shaft are arranged in the pulverizer cylindrical shell, the bottoms of the driving transmission shaft and the driven transmission shaft are connected to the bearing base seal cover, the driving transmission shaft and the driven transmission shaft are installed in the middle of the pulverizer cylindrical shell and are respectively provided with sanding vane plates, each one of the top and the bottom of the pulverizer cylindrical shell is provided with a raised wear-resistant end plate, and the raised wear-resistant end plate is an assembly which has a Chinese character Tu-shaped cross section and is composed of large cylinders and small cylinders with different diameters. The buffer damping noise-reduction pulverizer has the characteristics of high work efficiency, low energy consumption, damping and noise reduction.

Owner:陈烨

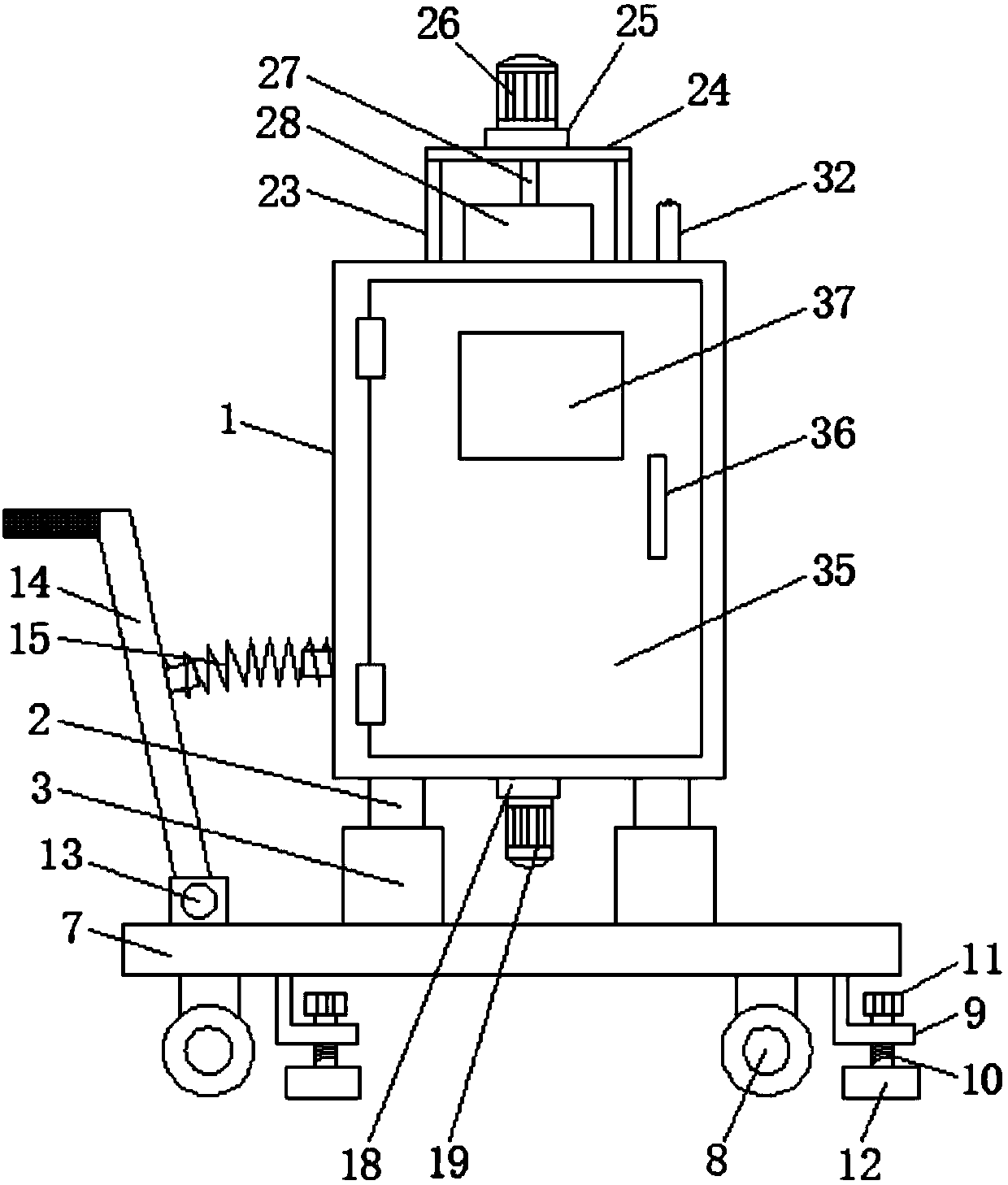

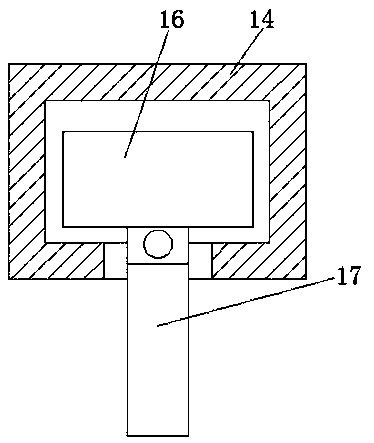

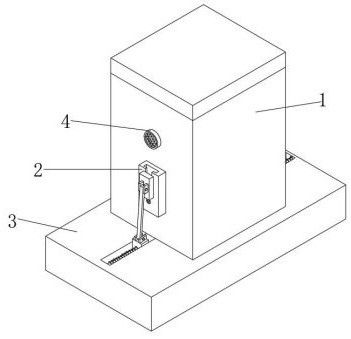

Monitoring mainframe box with heat dissipation function

InactiveCN112638121AImprove practicalityReduce contact areaNon-rotating vibration suppressionCasings/cabinets/drawers detailsPhysicsElectric machinery

The invention relates to a monitoring mainframe box with a heat dissipation function, and the monitoring mainframe box comprises a main body, a motor, a driving shaft, a lantern ring, a fan, a damping mechanism and a fixing mechanism. The fan is fixed through the fixing mechanism, and the fan is driven to rotate through the motor, so that wind power heat dissipation is realized; vibration during motor operation is damped through the damping mechanism, compared with an existing damping mechanism, the damping mechanism has the advantages that rotation of the driving shaft is limited, meanwhile, vibration of the driving shaft is buffered and damped, practicability is improved, meanwhile, balls are clamped through fixing balls and positioning balls, the contact area with the balls is reduced, and secondary vibration caused by friction force is reduced, so that the balls roll more stably, and compared with an existing fixing mechanism, the fixing mechanism has the advantages that a bolt is doubly fixed through the threads and a fixing assembly, the problem that the bolt slips is avoided through the fixing assembly, and a better fixing effect is achieved.

Owner:南京思达捷信息科技有限公司

Pipeline clogging point locating device

InactiveCN104613320BReduce layoutShock absorberPipeline systemsSatellite radio beaconingDisplay devicePigging

Owner:XIAN UNIV OF SCI & TECH

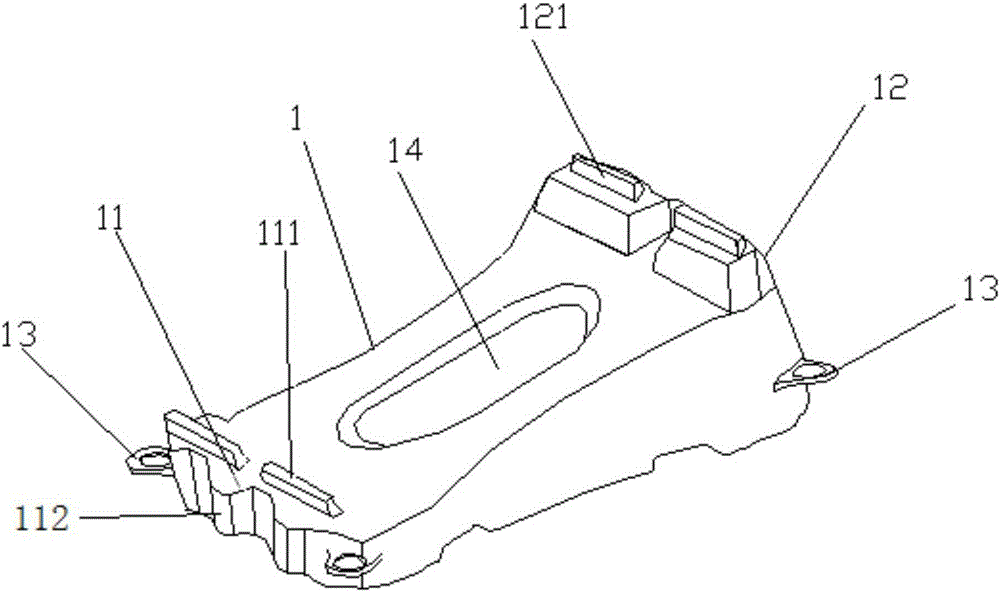

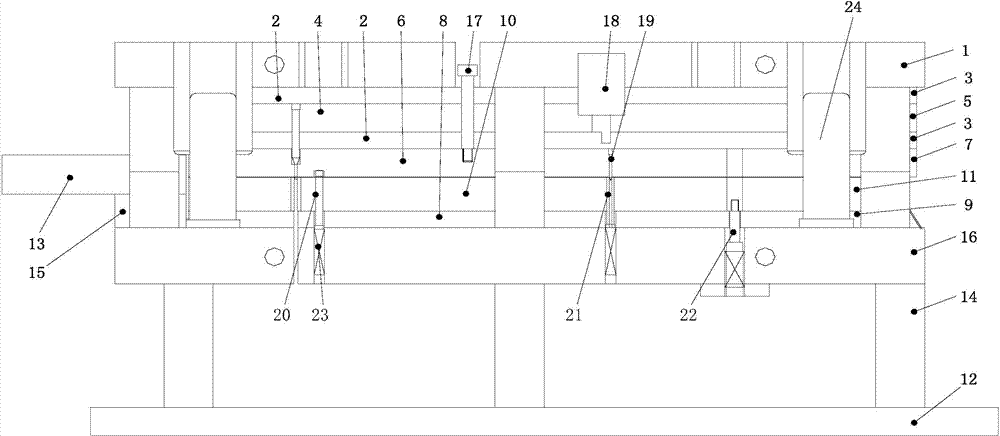

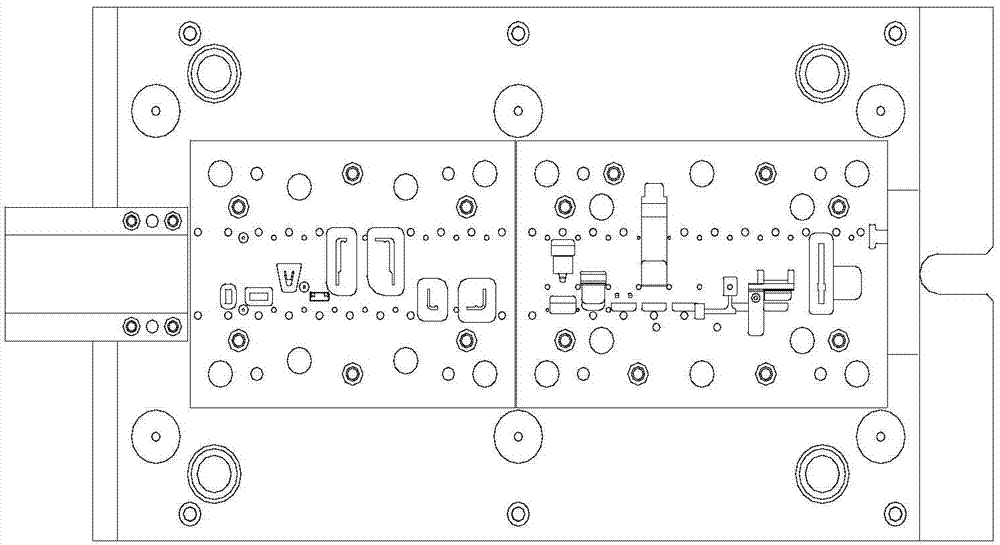

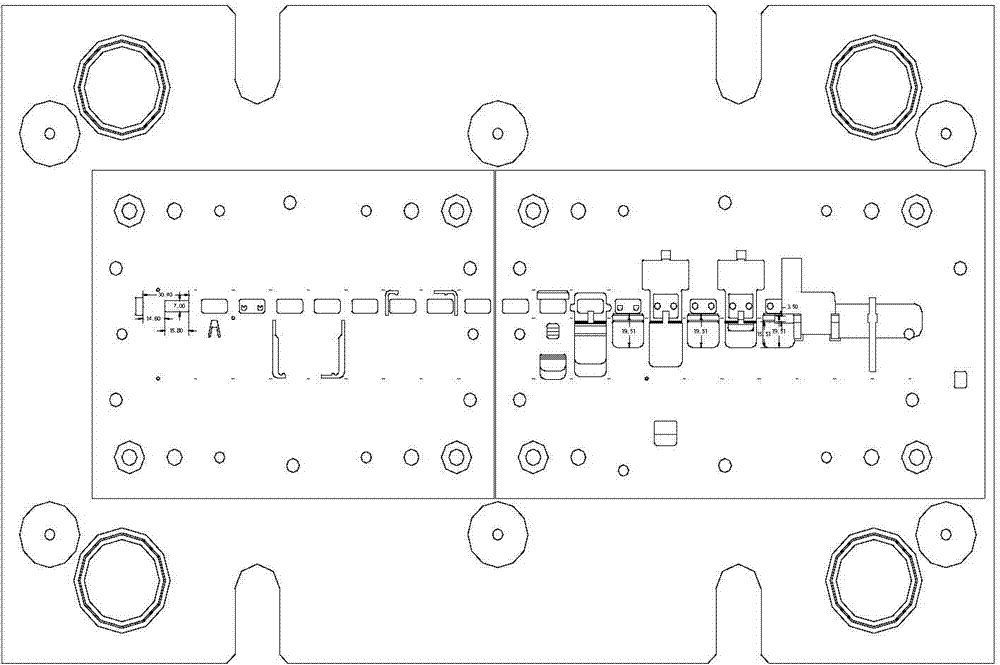

Progressive die for manufacturing spring chuck for fixing rear view mirror glass on car

InactiveCN104492934AWide range of useGood mold stabilityShaping toolsPerforating toolsRear-view mirrorEngineering

The invention relates to a progressive die for manufacturing a spring chuck for fixing rear view mirror glass on a car. Punching, forming and side cutting are carried out on raw materials, and therefore a product is formed. The die comprises an upper die body, a lower die body and a guide mechanism, and the upper die body is connected with the lower die body through the guide mechanism. Compared with the prior art, the progressive die has the advantages of being wide in use range, safe, reliable, convenient to overhaul and the like.

Owner:SHANDONG AOLIN CAR FITTINGS

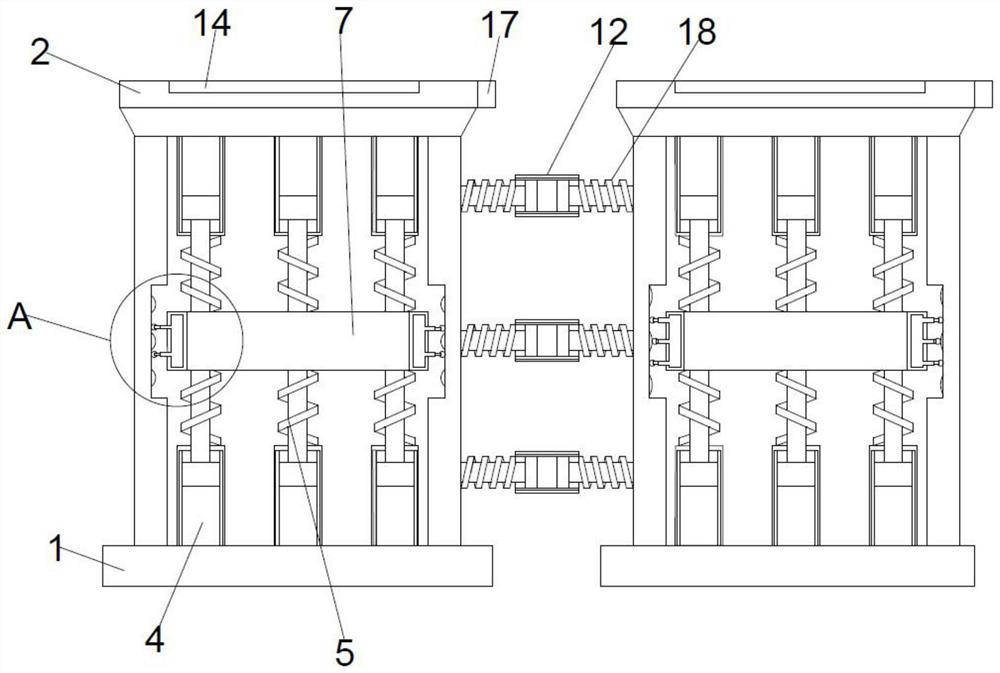

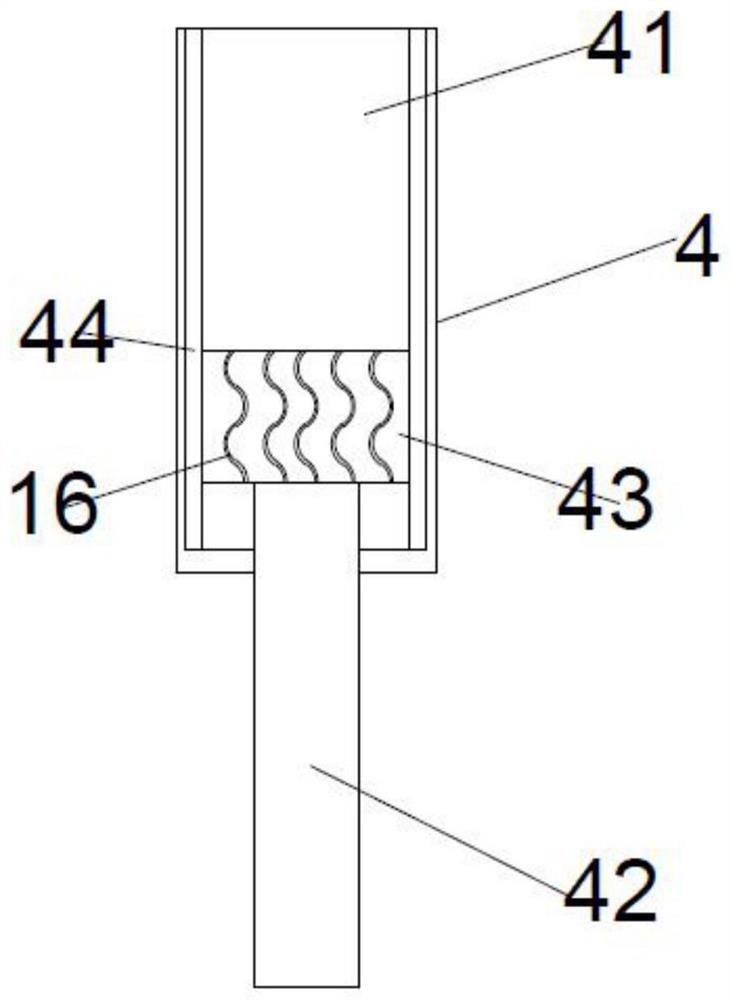

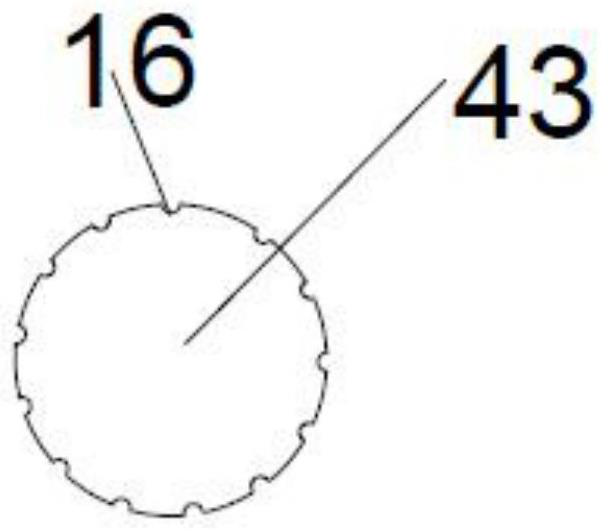

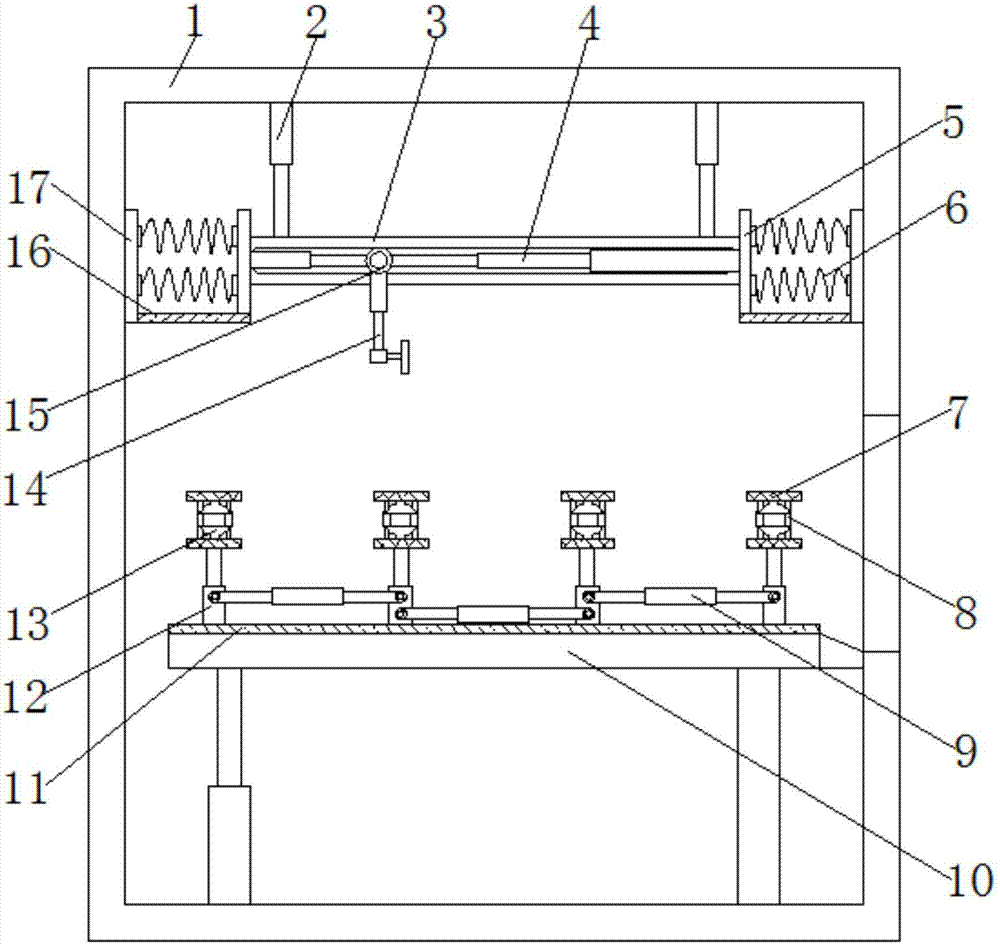

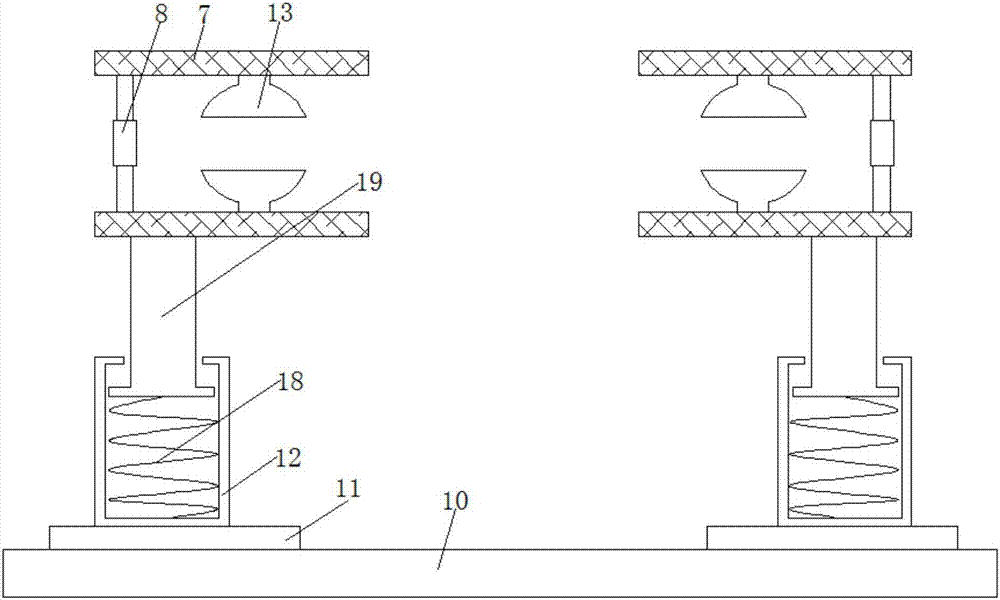

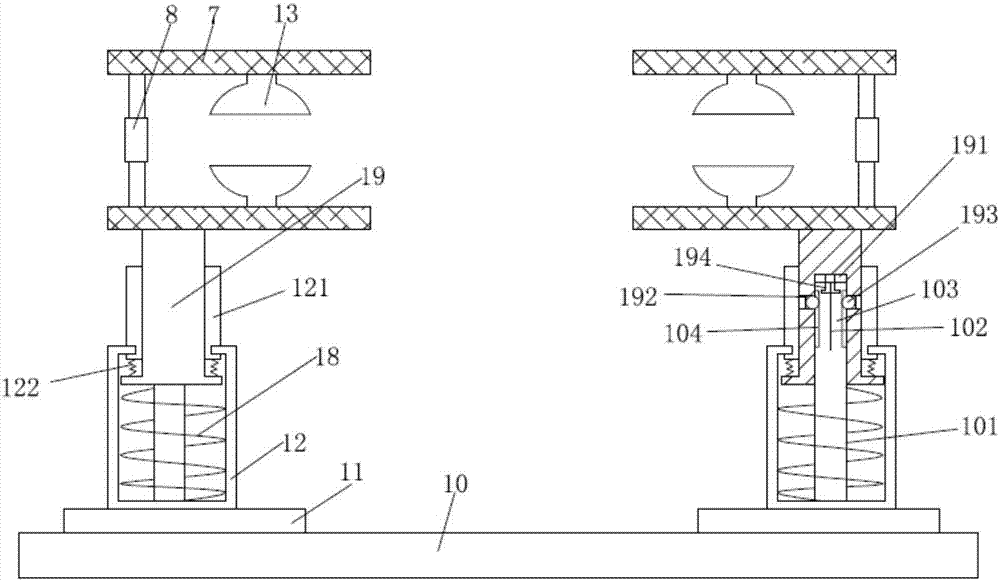

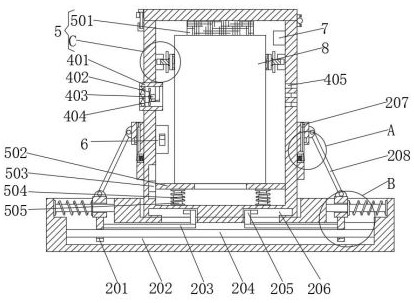

BIM-based fabricated damping device for constructional engineering

ActiveCN114033063AShock absorberAvoid damageProtective buildings/sheltersShock proofingVertical vibrationArchitectural engineering

The invention belongs to the technical field of constructional engineering equipment, and relates to a BIM-based fabricated damping device for constructional engineering, which comprises a plurality of fixed bases and further comprises damping columns; a fixing plate; a first shock absorption mechanism which is arranged in the shock absorption column and is used for reducing vertical vibration of the building structure generated by seismic waves when an earthquake occurs; and a second damping mechanism which is arranged between every two adjacent damping columns and used for relieving horizontal vibration of the building structure generated by seismic waves when an earthquake occurs. Through the arrangement of the first damping mechanism and the second damping mechanism, vibration of seismic waves on the building structure can be comprehensively blocked, damage of the earthquake to the building structure is reduced, the maintenance cost after the earthquake is reduced, and meanwhile, multiple first dampers arranged on the upper portion and the lower portion of the damping plate are matched with the corresponding first elastic pieces to conduct energy dissipation and absorption on seismic waves twice, vibration of the seismic waves is reduced to the minimum, and a building structure can be effectively protected.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

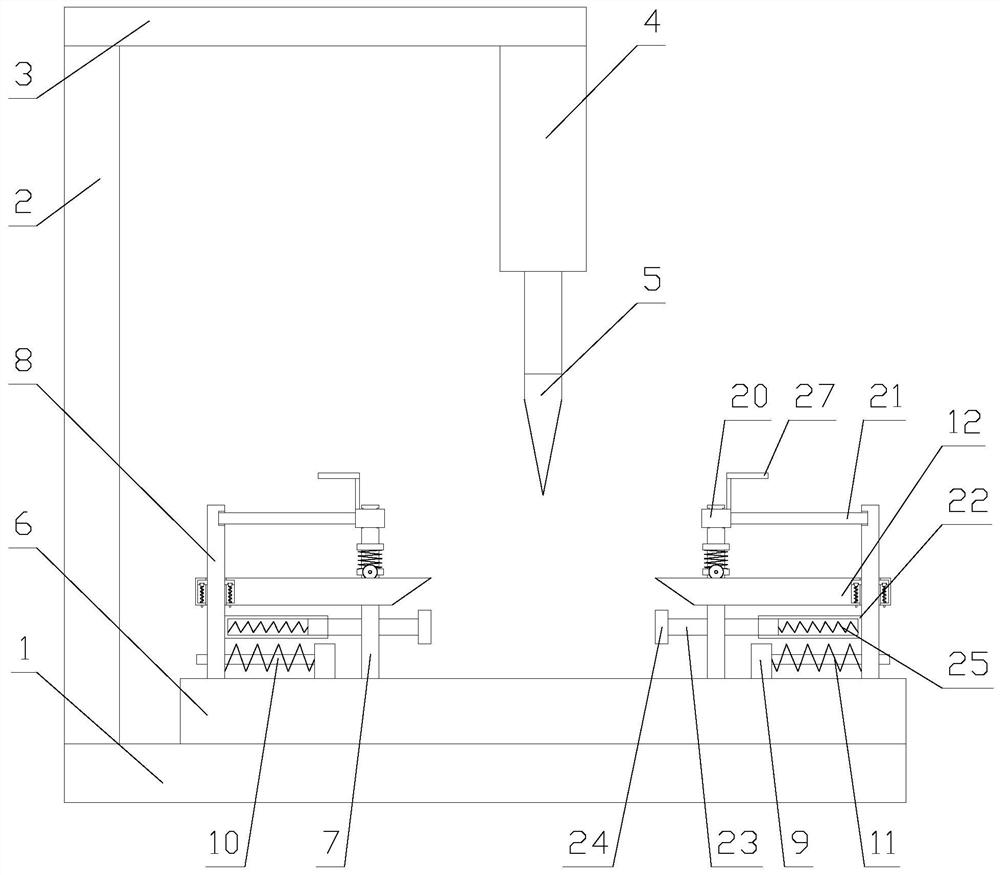

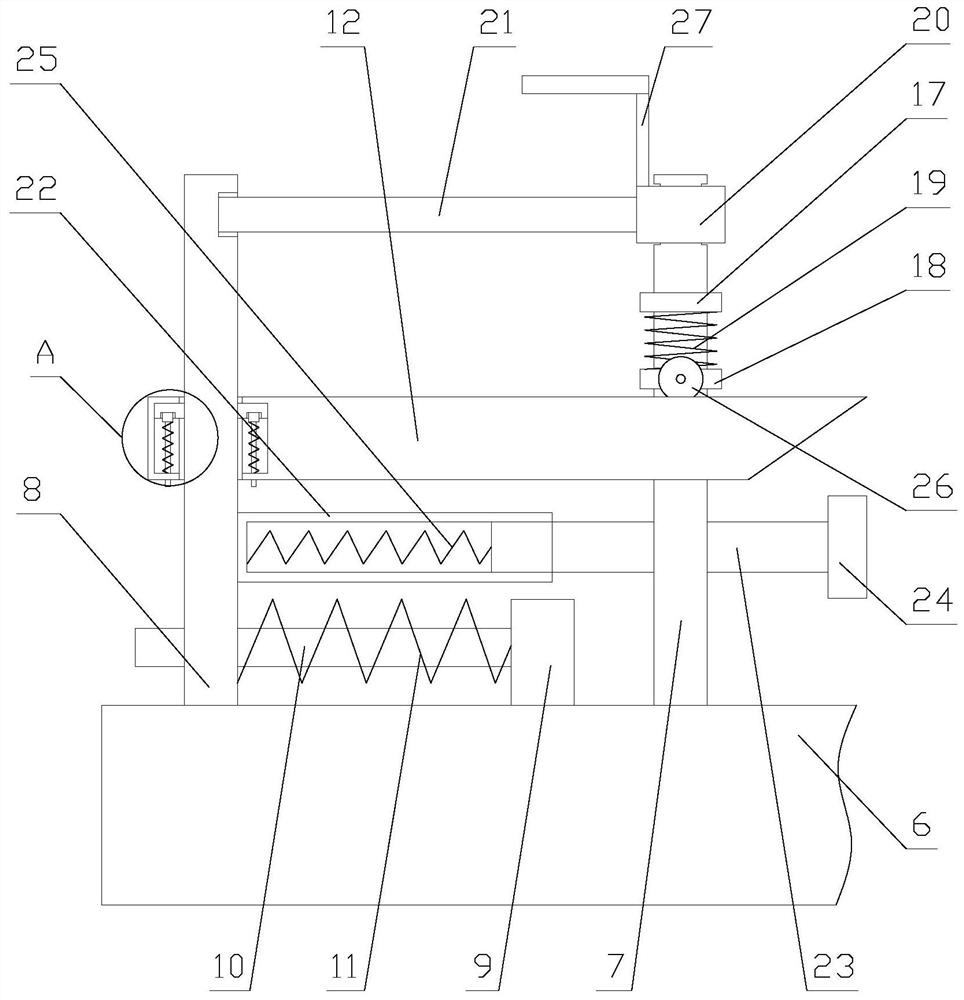

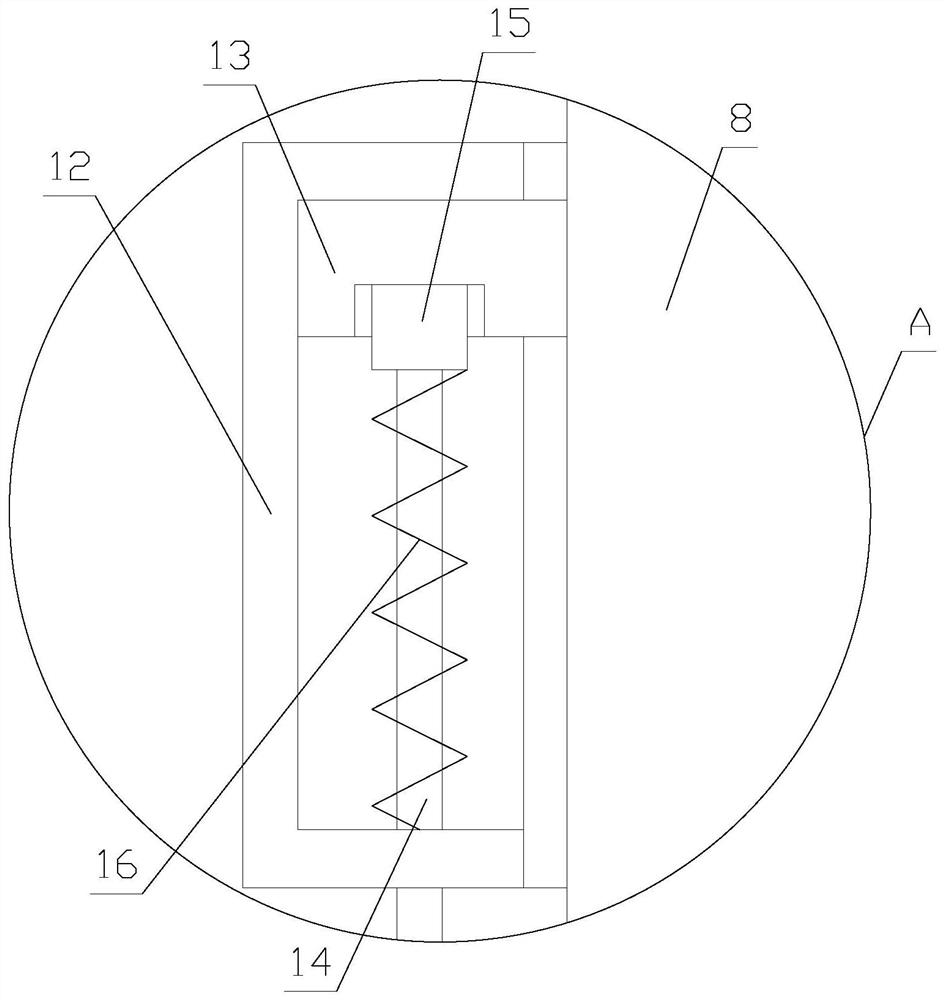

Metal workpiece punching device with good clamping effect

InactiveCN113084214AImprove clamping effectImprove practicalityPositioning apparatusVibration suppression adjustmentsEngineeringDrill bit

The invention relates to a metal workpiece punching device with a good clamping effect. The metal workpiece punching device comprises a base, a supporting rod, a cross rod, an air cylinder, a drill bit, an operation table and two clamping mechanisms, the clamping mechanisms are arranged on the operation table, the number of the clamping mechanisms is two, and the two clamping mechanisms are arranged on the two sides of the operation table correspondingly. According to the metal workpiece punching device with the good clamping effect, workpiece clamping is achieved through the clamping mechanism, and punching is achieved through operating the air cylinder, compared with an existing clamping mechanism, the clamping mechanism has the advantages that the top and the two sides of the workpiece are all clamped in an all-around mode, the clamping effect is improved, meanwhile, the clamping mechanism clamps the workpiece, vibration generated during workpiece punching is buffered and damped, the practicability is improved, and in addition, the workpiece is clamped through the restoring force of a spring, flexible clamping is adopted, the situation that the workpiece is scratched through rigid clamping is avoided, and the workpiece is protected.

Owner:南京鸿音工程技术有限公司

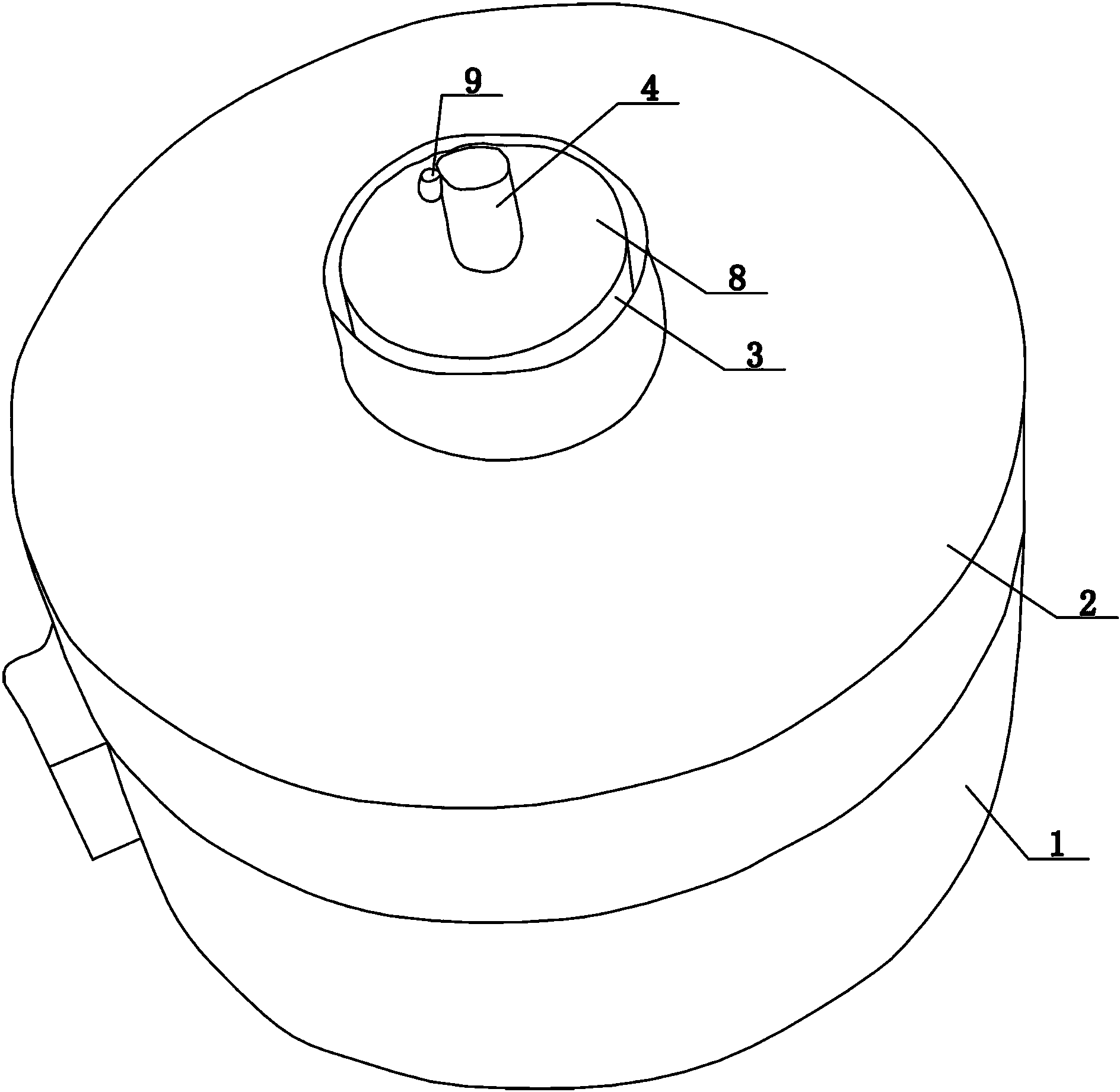

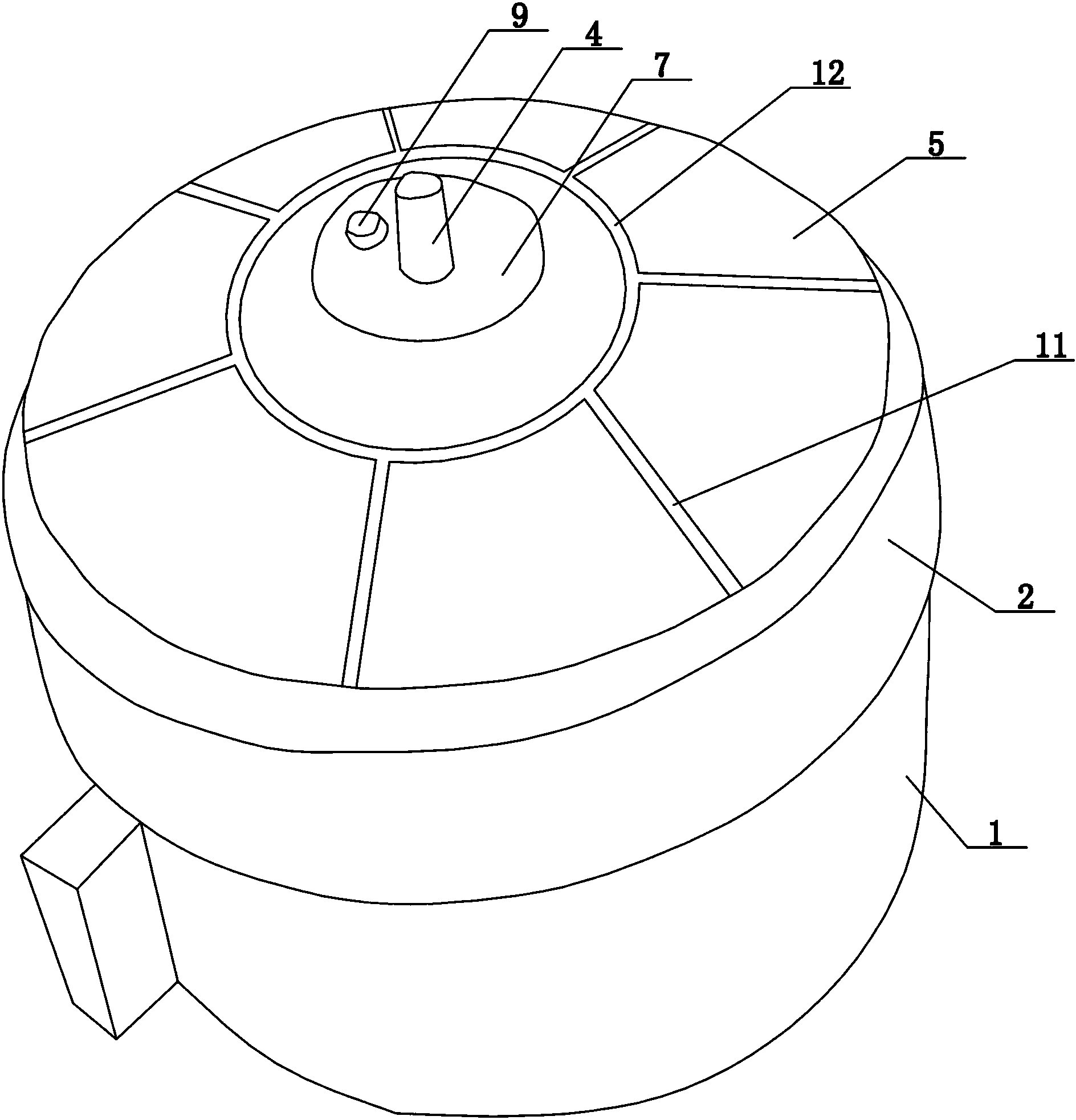

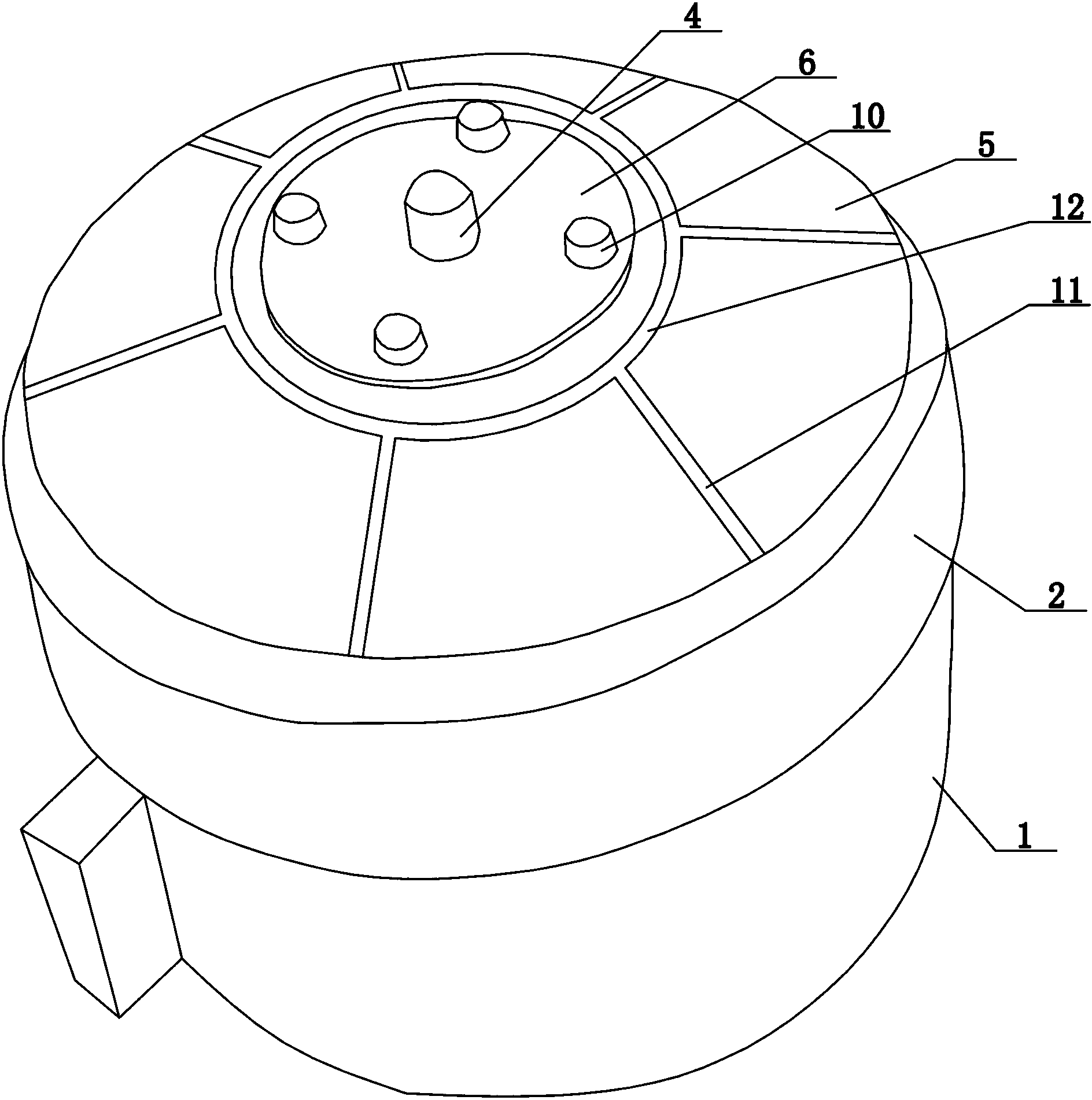

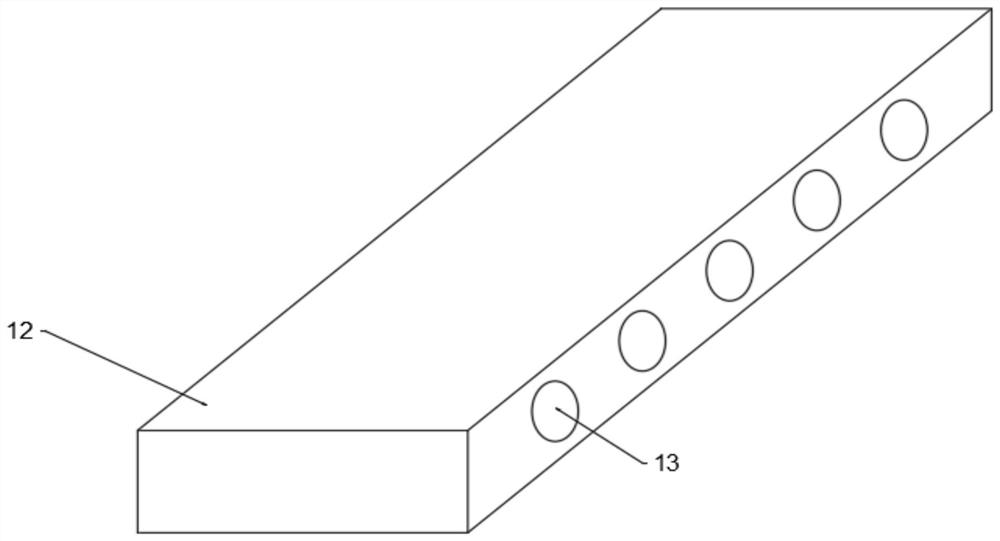

Inner rotor motor for fan

InactiveCN104218727APerformance is not affectedGuaranteed performanceSupports/enclosures/casingsCast ironEngineering

The invention discloses an inner rotor motor for a fan. The inner rotor motor comprises a cast iron shell (1), a plastic housing (2), a revolving shaft (3) and a water-proof cover (5), wherein the end part of the revolving shaft (3) extends out of the plastic housing (2); a threaded connecting rod (4) is arranged on the end part of the revolving shaft (3); the water-proof cover (5) covers the end part of the revolving shaft (3); a first vibration isolation pad (6) sleeves the threaded connecting rod (4); a plurality of elastic columns (10) which are uniformly distributed in the circumferential direction are arranged on the upper surface of the first vibration isolation pad (6); and a first water guide groove (12) and a plurality of second water guide groove (11) which are distributed radially are formed in the outer surface of the water-proof cover (5). The inner rotor motor is suitable for a use environment with a high waterproofing grade requirement, and the performance of the inner rotor motor for the fan in the use environment with the high waterproofing grade requirement is ensured.

Owner:NINGBO LIONBALL VENTILATOR

Magnetic steel sheet cutting and separation device

ActiveCN107999892AImprove efficiencyEasy to useMaintainance and safety accessoriesEngineeringMachining process

The invention discloses a magnetic steel sheet cutting and separation device which comprises a supporting frame; first connecting rods are fixedly arranged at the inner wall of the upper end of the supporting frame through screws; a rail is fixedly arranged at one ends of the first connecting rods through screws; a sliding groove is formed in the side wall of the rail; the inner wall of the sliding groove is slidingly connected with a sliding rod; the side walls of the two ends of the sliding rod are connected with supporting rods through bolts; the side walls, close to the rail, of the supporting frame are slidingly connected with fixed plates; the side wall of the upper end of a supporting plate is connected with a first sliding rail through rivets; and the side wall of the first slidingrail is slidingly connected with second fixed rods. With the adoption of the first connecting rods, the rail, the sliding rod, a hydraulic rod and the supporting rods, the first connecting rods can drive the rail to be interlocked with the sliding rod and the hydraulic rod to be subjected to height adjustment, and the supporting rods can drive the sliding rod and the hydraulic rod to make linearmotion along the sliding groove, so that the efficiency of magnetic steel in the cutting and separation process is improved, the usability of the magnetic steel sheet cutting and separation device isimproved and the labor intensity in the machining process is lowered.

Owner:嘉兴市鹏程磁钢有限公司

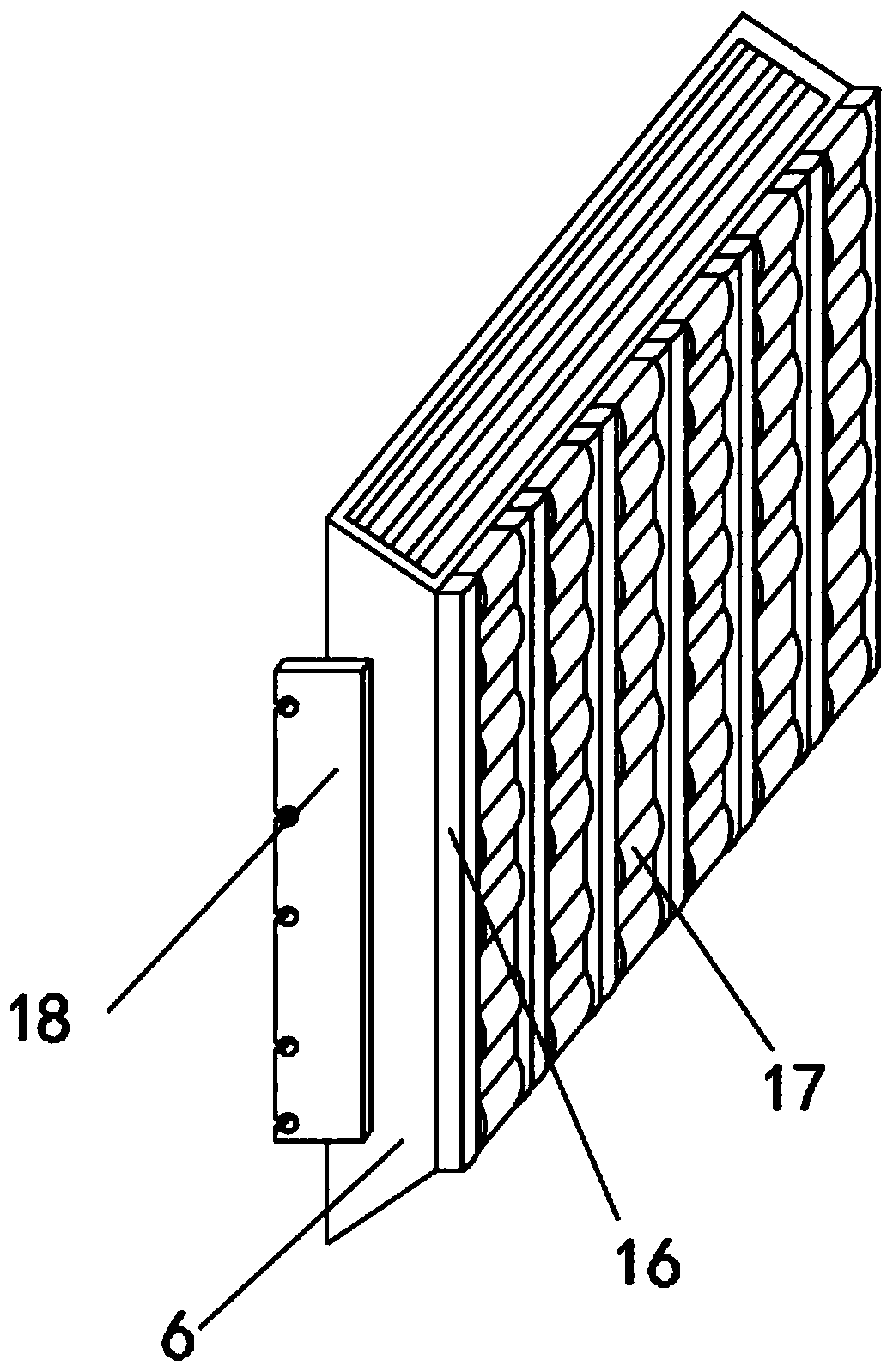

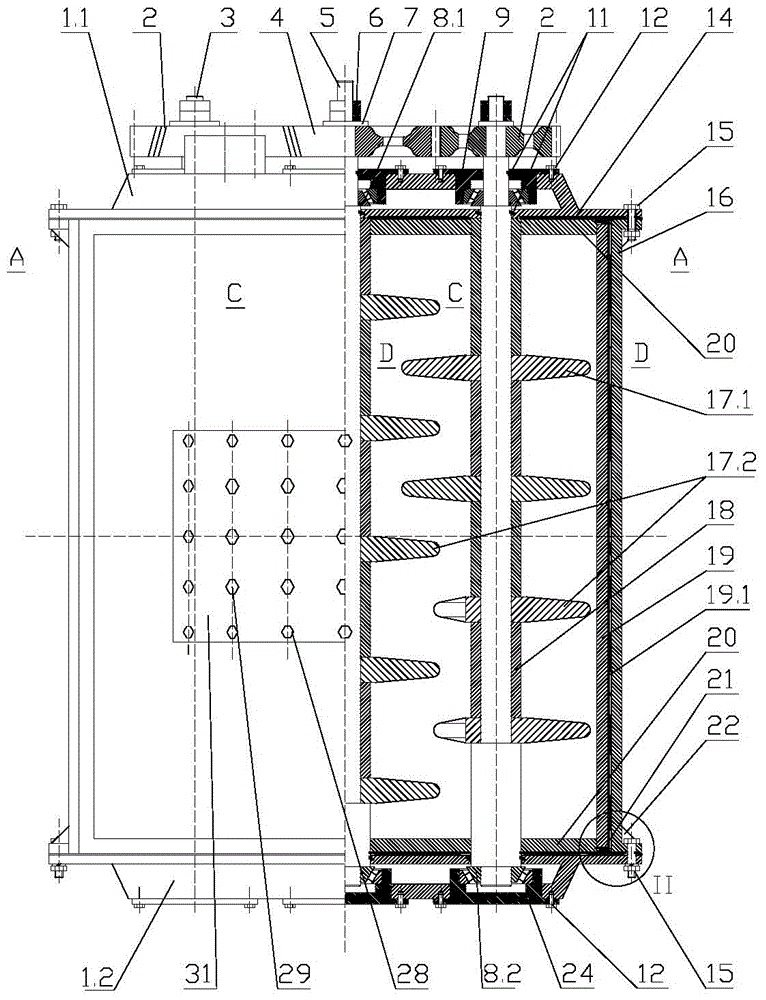

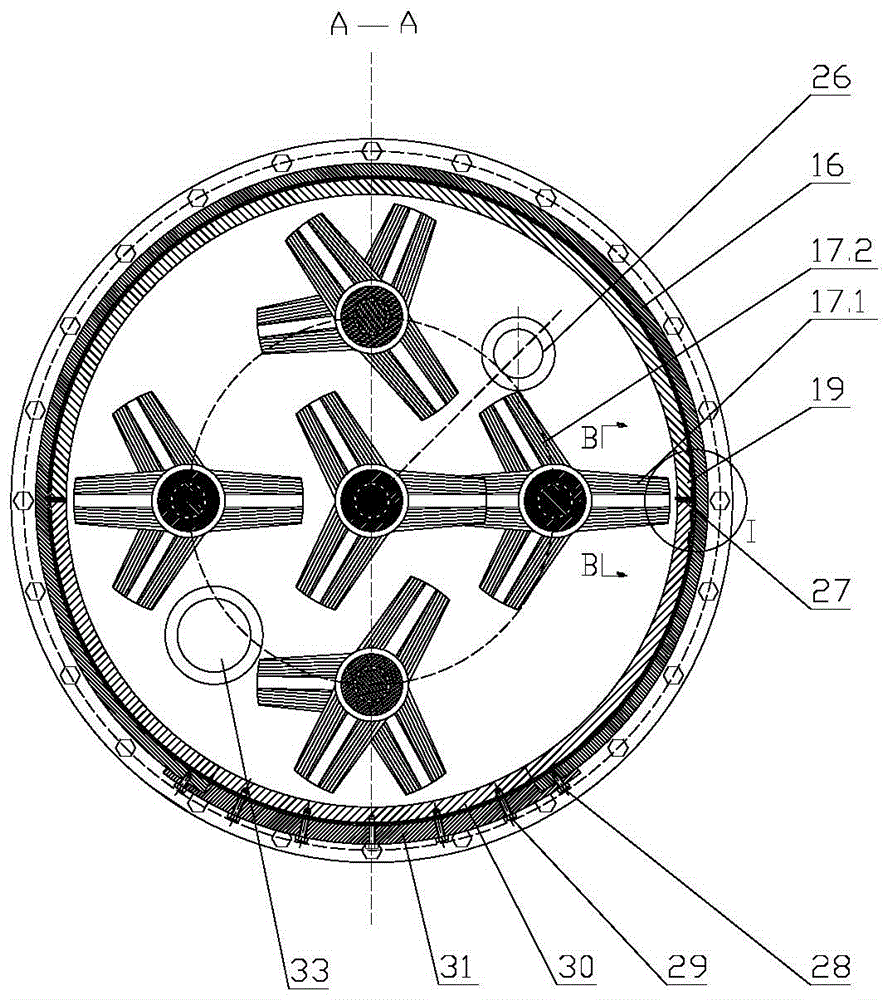

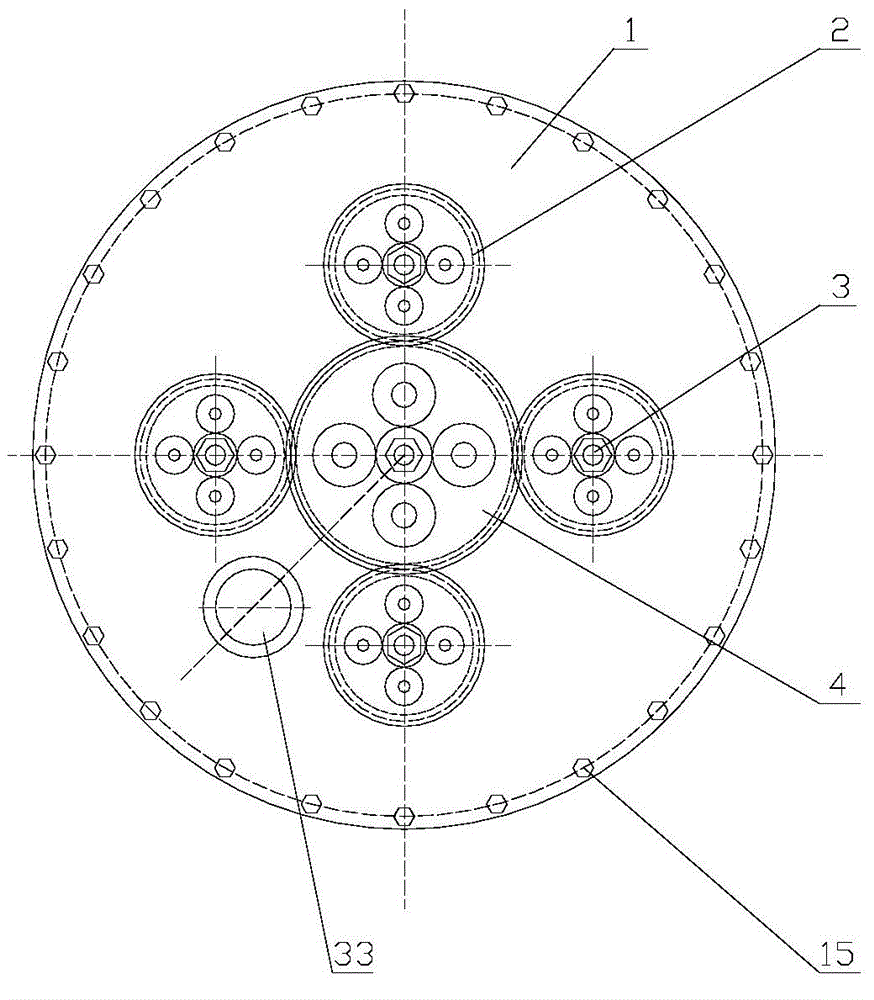

Rotary seal box environment-friendly crusher

InactiveCN104759317AReduce energy consumptionImprove work efficiencyGrain treatmentsEngineeringEnergy consumption

The invention provides a rotary seal box environment-friendly crusher. The crusher comprises upper and lower bearing housings, driving and driven transmission shafts, driving and driven gears, a bearing block ventilation cover and a bearing block stuffy cover and is characterized in that a crusher barrel is cylindrical; the bearing housings are installed at the upper and lower parts of the crusher barrel respectively; the upper and lower bearing housings are respectively connected with the bearing block ventilation cover and the bearing block stuffy cover; the driving and driven transmission shafts penetrate through the bearing block ventilation cover; the middle parts of the driving and driven transmission shafts are arranged in the crusher barrel; the bottoms of the driving and driven transmission shafts are connected with the bearing block stuffy cover; sanding hammers are installed on the transmission shafts respectively and are connected with the transmission shafts by splines; a wearproof liner is installed in the crusher barrel and is a cylinder formed by two semicircular arc plates; a wearproof liner opposite joint damping sealing gasket is installed in a gap between the two semicircular arc plates of the wearproof liner; a rotary seal ring is fixed together with the driving and driven transmission shafts via rotary seal ring set screws; a seal cover is installed at the top of the upper bearing housing. The crusher has the characteristics of improvement of the work efficiency, reduction of the energy consumption, damping and noise reduction.

Owner:马宏

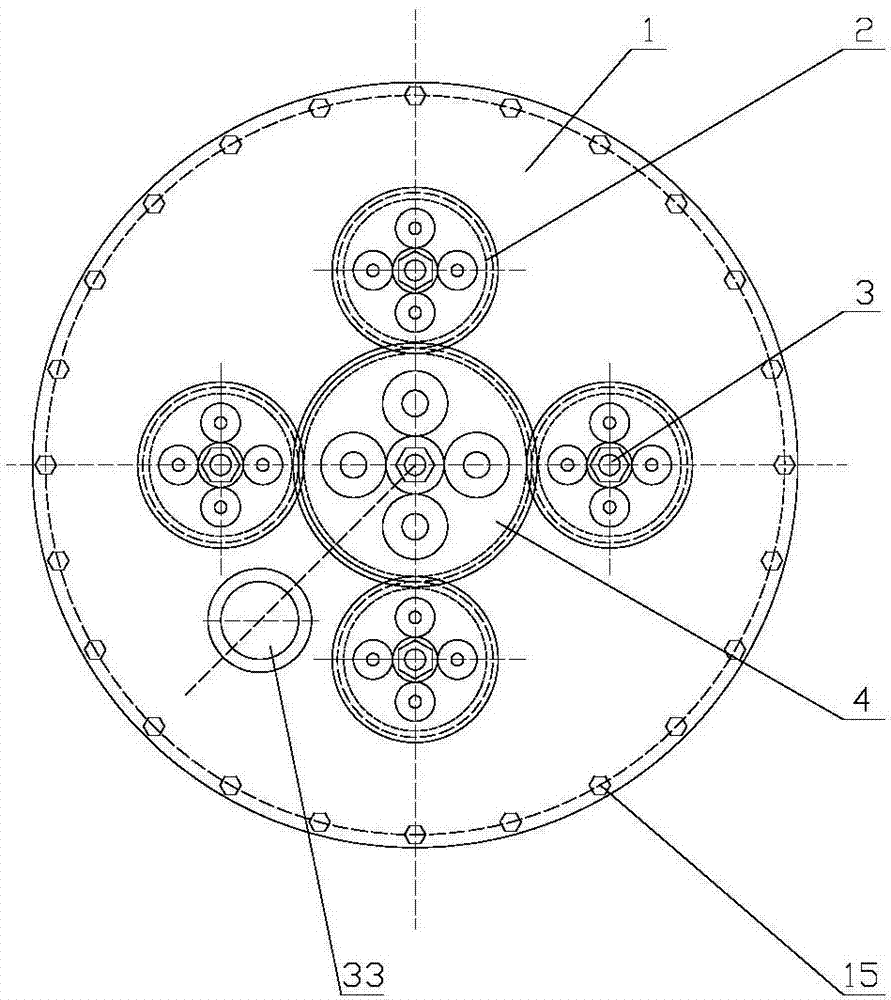

Damping rotary seal multi-rotary-hammer crusher

InactiveCN104759318AReduce energy consumptionImprove work efficiencyGrain treatmentsSet screwDrive shaft

The invention provides a damping rotary seal multi-rotary-hammer crusher. The crusher comprises upper and lower bearing housings, driving and driven transmission shafts, driving and driven gears, a bearing block ventilation cover and a bearing block stuffy cover and is characterized in that a crusher barrel is cylindrical; the bearing housings are installed at the upper and lower parts of the crusher barrel respectively; the upper and lower bearing housings are respectively connected with the bearing block ventilation cover and the bearing block stuffy cover; upper and lower tapered roller bearings are installed in the upper and lower bearing housings; the driving and driven transmission shafts penetrate through the bearing block ventilation cover; the middle parts of the driving and driven transmission shafts are arranged in the crusher barrel; the bottoms of the driving and driven transmission shafts are connected with the bearing block stuffy cover; sanding hammers are installed on the transmission shafts respectively and are connected with the transmission shafts by splines; a wearproof liner is installed in the crusher barrel; a wearproof liner damping sleeve is inlaid in the outer wall of the wearproof liner; a rotary seal ring is fixed together with the driving and driven transmission shafts via rotary seal ring set screws. The crusher has the characteristics of improvement of the work efficiency, reduction of the energy consumption, damping and noise reduction.

Owner:马宏

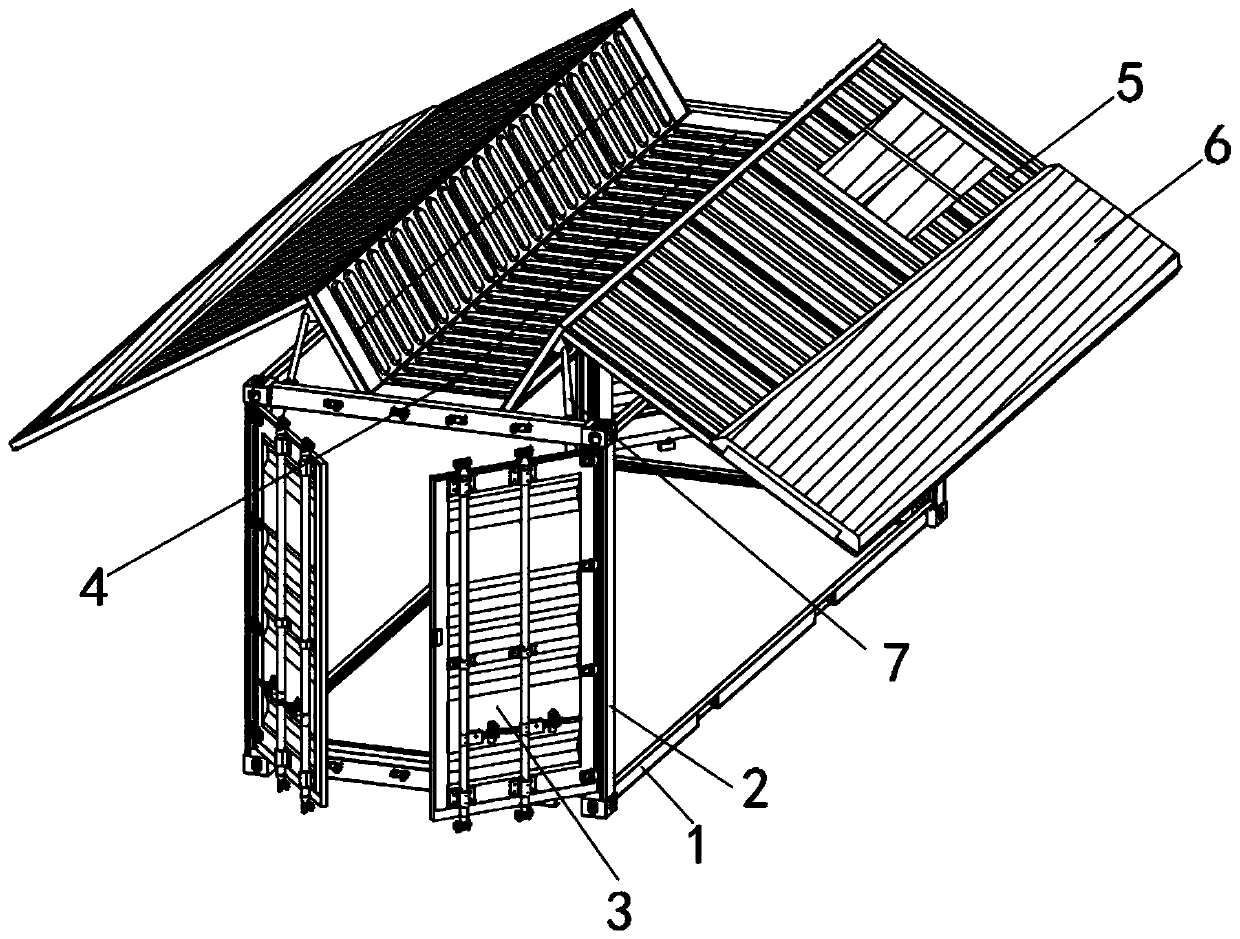

Expansion type container module room with safety protection structure

ActiveCN110847638AIncrease the bearing area of the bottomShock absorberSpecial buildingHeat proofingEngineeringStructural engineering

The invention discloses an expansion type container module room with a safety protection structure. The expansion type container module room comprises a bottom frame, wherein a mounting frame is clamped at the top of the bottom frame, two opening and closing doors are connected with the front end of the mounting frame, a connecting plate is installed at the top of the mounting frame, expansion plates are connected with the two sides of the connecting plate, and driving assemblies are connected between the bottom, close to the two sides, of each expansion plate and the side wall of the mountingframe. According to the expansion type container module room, a pressure-resistant seat is arranged at the bottom of the bottom frame so that the pressure resistance of the whole container module room can be effectively improved, protective plates are arranged on the side walls of the expansion plates, thus a better protective effect can be achieved, the anti-impact performance of the module roomis improved, the driving assemblies are arranged to connect the expansion plates and the mounting frame, the two expansion plates can be expanded outwards through the driving of the driving assemblies, then the whole module room can be unfolded, the interior of the module room can be conveniently cleaned, and articles can be transported.

Owner:SUZHOU TIANDI COLORBOND MFG

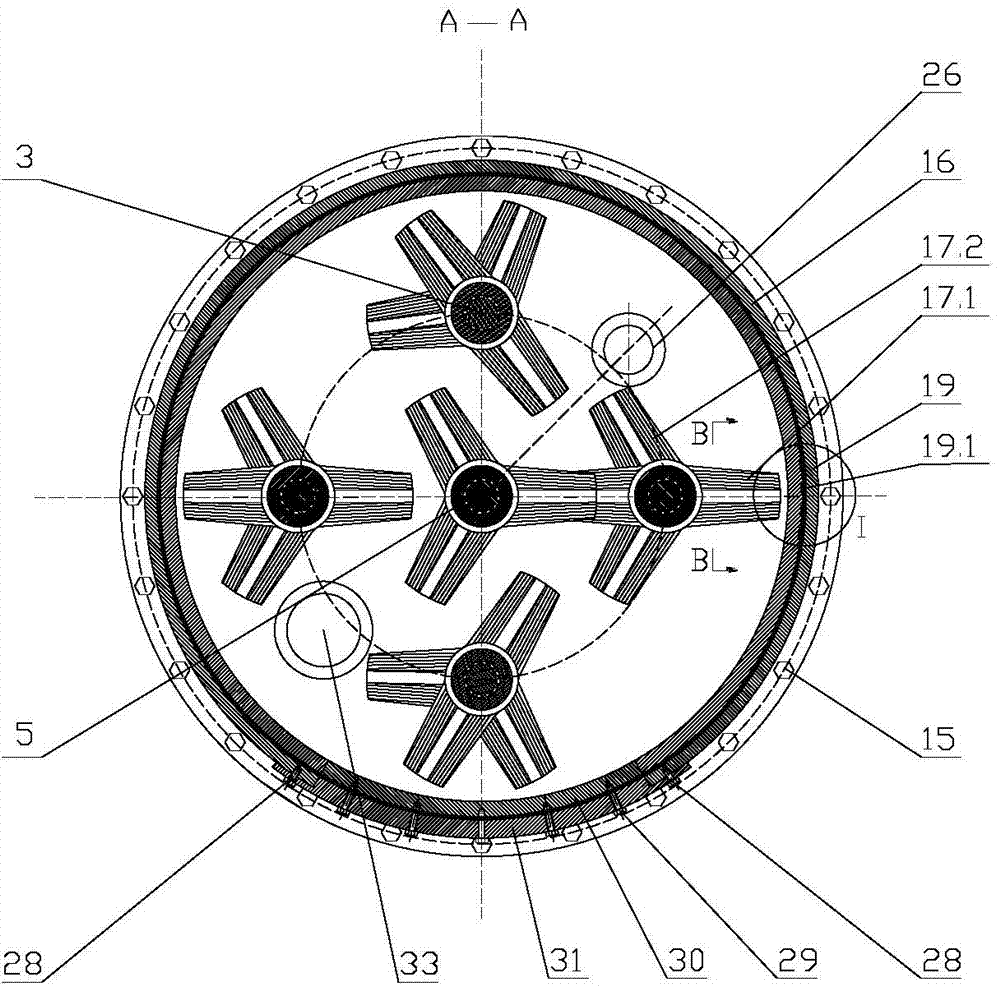

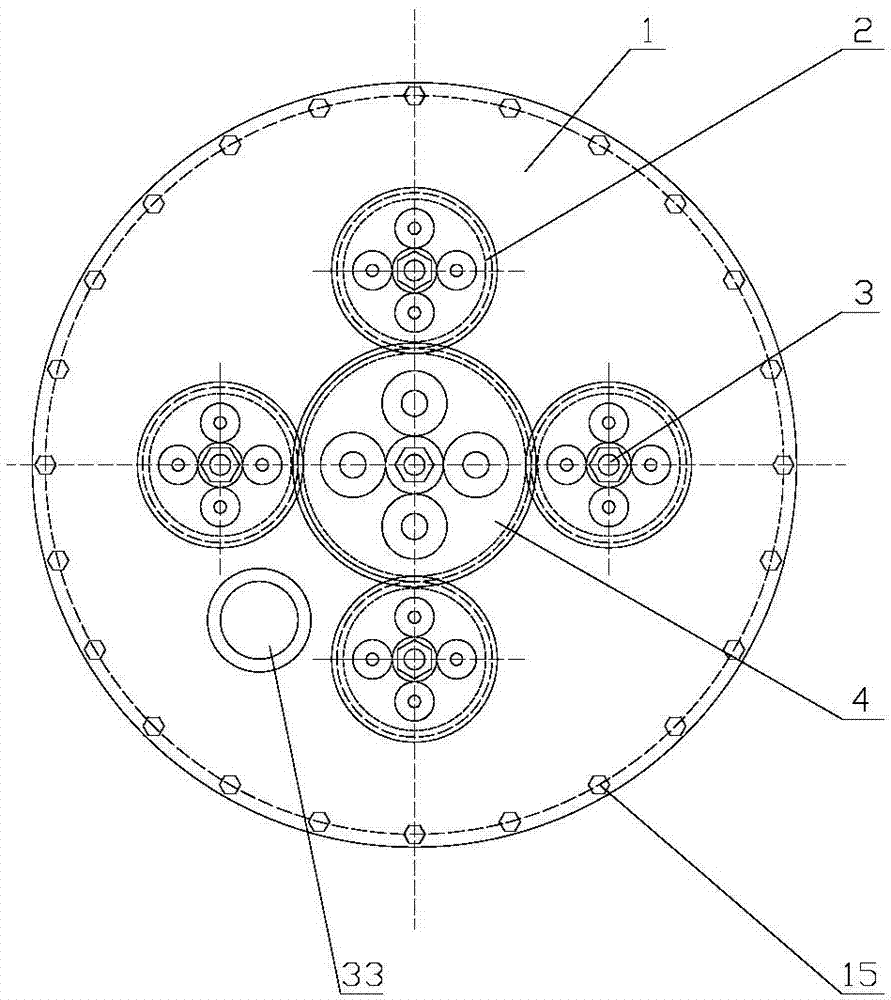

Multi-shaft rotation hammer staggered shear crusher

InactiveCN104815724AImprove work efficiencyReduce energy consumptionGrain treatmentsRoller bearingEngineering

The invention relates to a multi-shaft rotation hammer staggered shear crusher, which is characterized in that the crusher cylinder is a cylindrical cylinder, the upper portion and the lower portion of the crusher cylinder are respectively provided with a bearing box, the upper bearing box and the lower bearing box are respectively connected with a bearing seat through cover and a bearing seat sealed cover, an upper cone roller bearing and a lower cone roller bearing are arranged in the upper bearing box and the lower bearing box, a drive transmission shaft and a driven transmission shaft penetrate through the bearing seat through cover, the middle portions are arranged in the crusher cylinder, the bottom portions are connected with the bearing seat sealed cover, the transmission shafts are respectively provided with a sanding hammer, the sanding hammer is connected with the transmission shaft through spline, a drive gear and a driven gear are inclined tooth cylinder gears, a wear resistance lining cylinder is arranged in the crusher cylinder, a wear resistance lining cylinder shock-reducing sleeve is embedded on the outer wall of the wear resistance lining cylinder, the wear resistance lining cylinder is a cylinder formed from two semi-arc plates, and a wear resistance lining cylinder seam-aligning shock-reducing sealing pad is arranged in the gap of the two semi-arc plates of the wear resistance lining cylinder. The multi-shaft rotation hammer staggered shear crusher has characteristics of work efficiency improving, energy consumption reducing, shock reducing, and noise reduction.

Owner:UNIV OF JINAN +1

Damping, shock absorbing and noise reducing staggered multi-hammer crusher

InactiveCN104841518AImprove work efficiencyReduce energy consumptionGrain treatmentsWear resistantEngineering

A damping, shock absorbing and noise reducing staggered multi-hammer crusher comprises an upper bearing box, a lower bearing box, a driving transmission shaft, a driven transmission shaft, a driving gear, a driven gear, a bearing seat through cap and a bearing seat blank cap; the barrel of the crusher is a cylindrical barrel, and the upper portion and the lower portion of the crusher barrel are respectively provided with the bearing boxes; the upper bearing box and the lower bearing box are respectively connected with the bearing seat through cap and the bearing seat blank cap; an upper tapered roller bearing is arranged in the upper bearing box, and a lower tapered roller bearing is arranged in the lower bearing box; the driving transmission shaft and the driven transmission shaft respectively traverse through the bearing seat through cap, the middle portion of the bearing seat through cap is in the crusher barrel, and the bottom of the bearing seat through cap is connected with the bearing seat blank cap; the driving transmission shaft and the driven transmission shaft are respectively provided with sand beating hammers, the transmission shafts are provided with the sand beating hammers, and the sand beating hammers are connected with the transmission shafts through splines; and a wear resistant bushing is arranged in the crusher barrel, the wear resistant bushing is a cylinder composed of two semi-circular plates;, and a wear resistant bushing butt-seam damping sealing gasket is arranged in a gap between the two semi-circular plates of the wear resistant bushing. The crusher has the characteristics of working efficiency increase, energy consumption reduction, damping and noise reduction.

Owner:UNIV OF JINAN

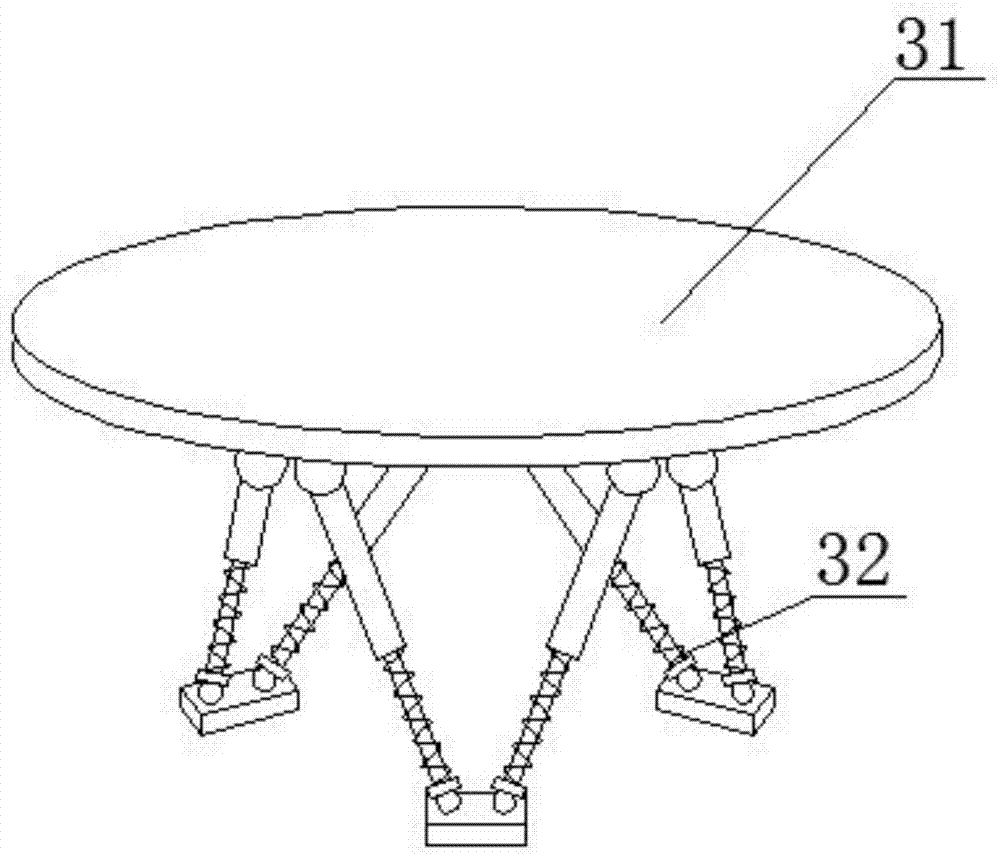

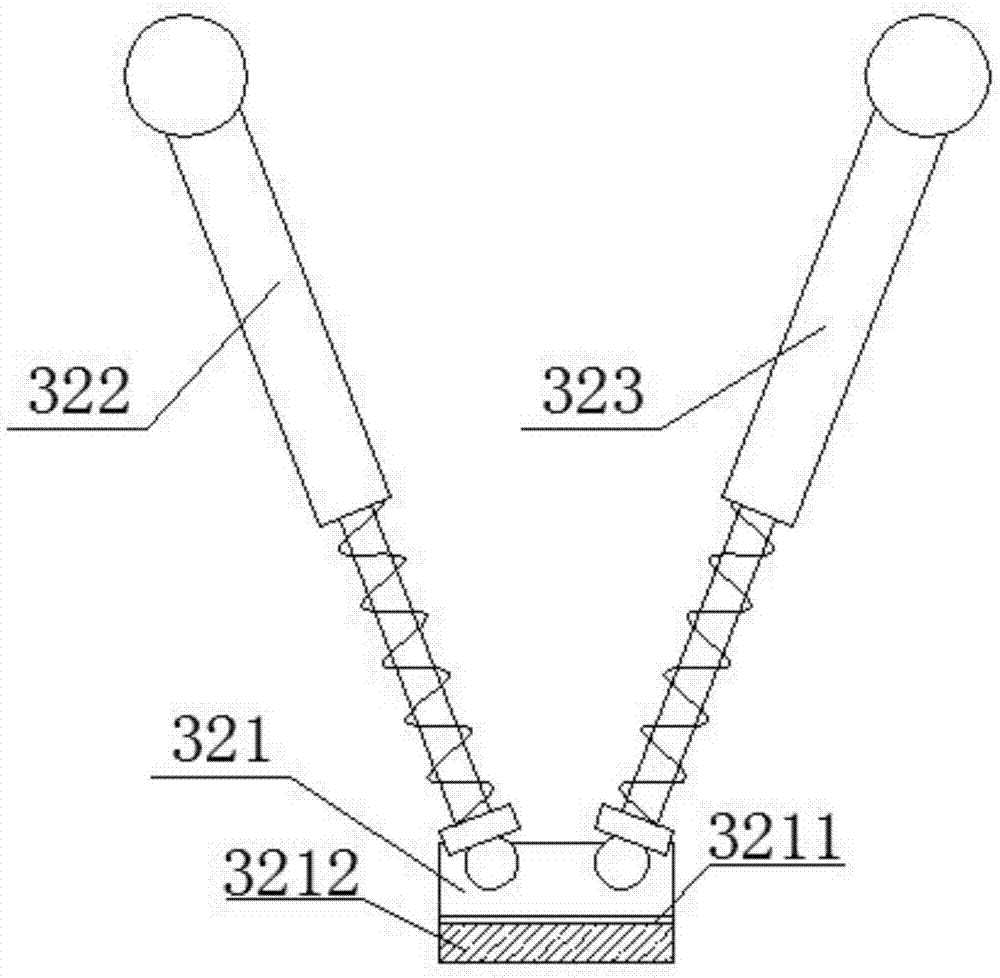

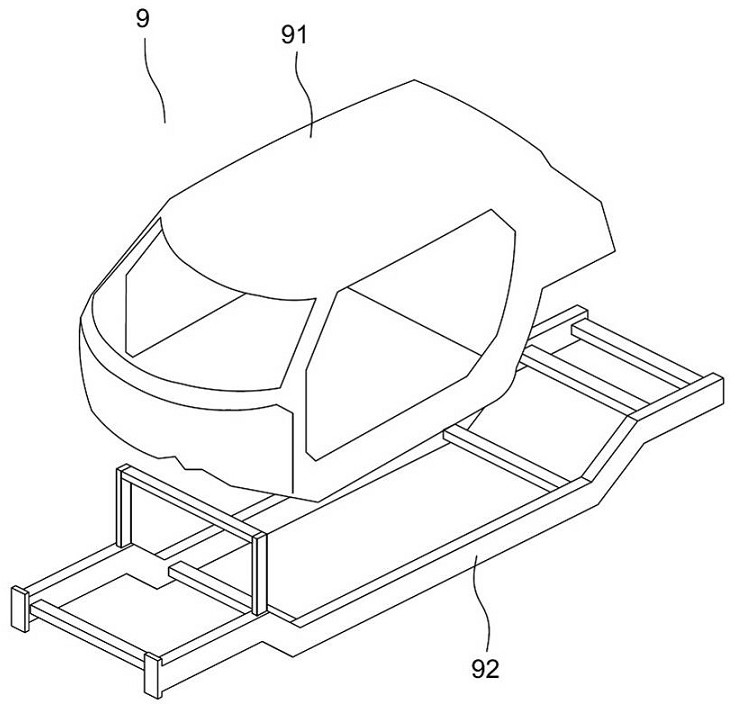

Aerial camera with professional tripod

InactiveCN107512389AGuarantee a safe landingShock absorberAlighting gearRotocraftPropellerStructural engineering

The invention discloses an aerial camera with a professional tripod. The aerial camera comprises an aerial camera main body and a camera arranged at the bottom of the aerial camera main body, wherein multiple sets of wings with propellers are arranged on the aerial camera main body; a damping device is arranged at the bottom at one end of the wings; the damping device comprises a connecting plate and a damping tripod; the connecting plate is connected with the bottom of the wings; the damping tripod comprises three sets of adjusting components which are distributed along the peripheral direction of the connecting plate; each adjusting component comprises a base; a left expansion link and a right expansion link are hinged on the base; the left expansion link and the right expansion link are arranged in V shape; and the other ends of the left expansion link and the right expansion link are both hinged with the connecting plate. According to the invention, the damping device is arranged, the V-shaped damping tripod is arranged and a triangular structure is formed between the damping tripod and the connecting plate, so that the damping and stabilizing functions are achieved and the safe landing of the aerial camera is guaranteed.

Owner:成都鑫晨航空科技有限公司

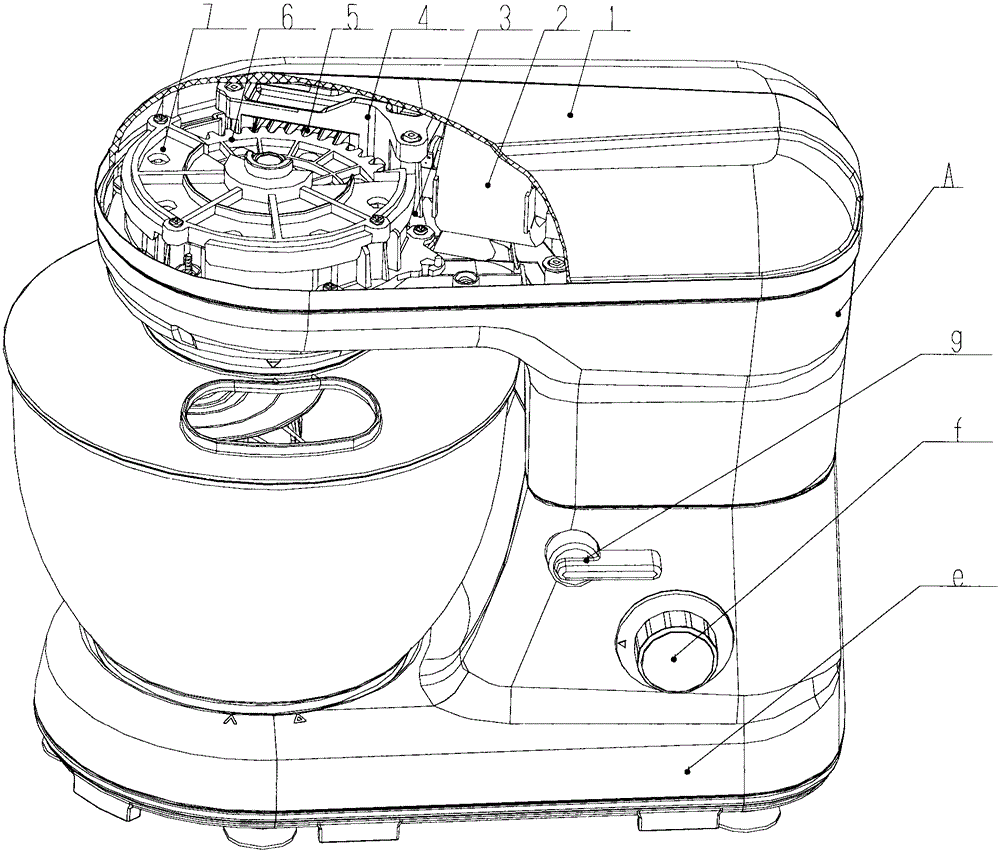

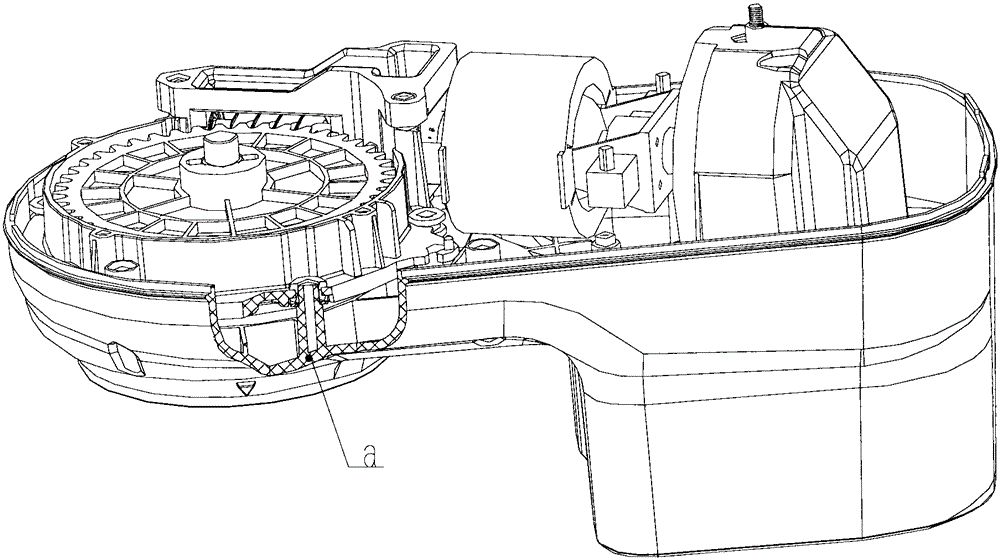

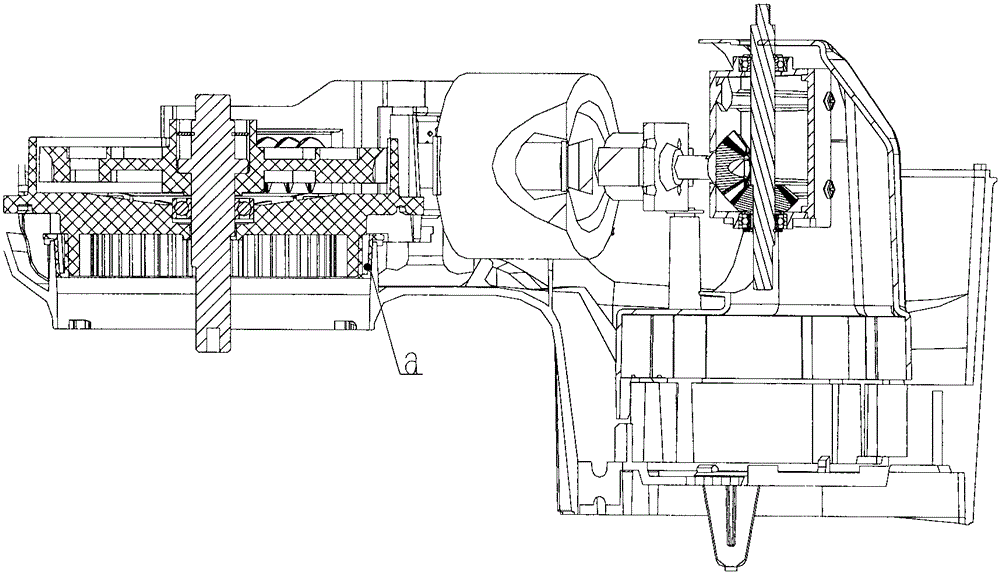

Transmission mechanism of dough kneading machine

InactiveCN105053100AImprove work efficiencyReduce noiseMixing/kneading structural elementsGear wheelEngineering

The invention discloses a transmission mechanism of a dough kneading machine; the transmission mechanism includes an upper cover, a motor, a gear box, a motor bracket, a worm, a helical gear and a gear cover; the motor is fixedly mounted on the motor bracket; the worm is connected with a motor output shaft; the helical gear is mounted in the gear box and is meshed with a worm gear; the gear cover is fixedly connected at the top of the gear box; the gear box is fixed on a main bracket. With adopting of the worm and helical gear transmission structure, the work efficiency is improved, and the noise is reduced; transmission of the worm and the motor is in transitional connection through screw threads, the motor bracket, the motor and the worm always keep at a same straight line, and the concentricity can be well guaranteed; the motor adopts a hanging structure, vibration and noise are reduced, and the service life of the motor is improved; and a galvanized sheet bracket is independently used for hanging the motor, the structure is simple, and the cost is low.

Owner:宁波肴邦电器有限公司

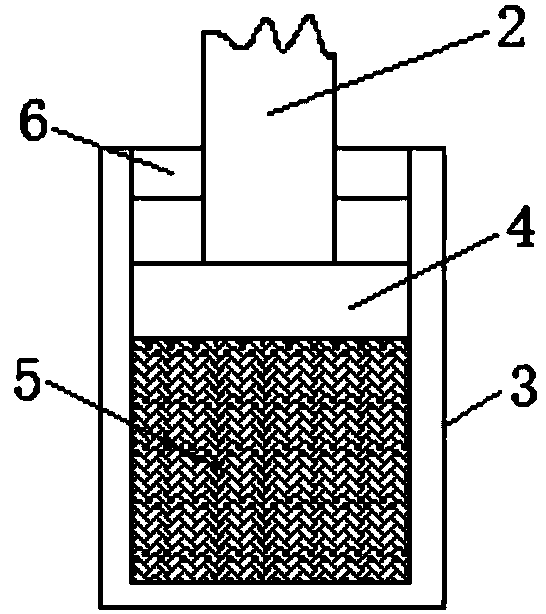

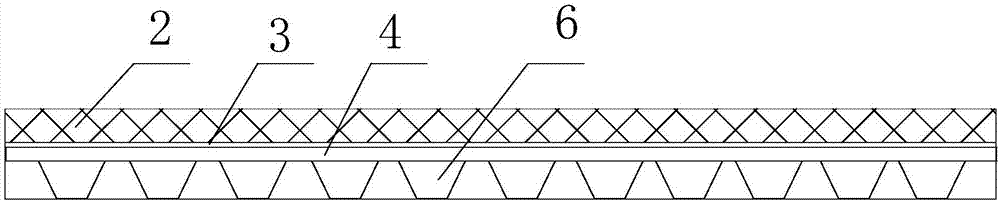

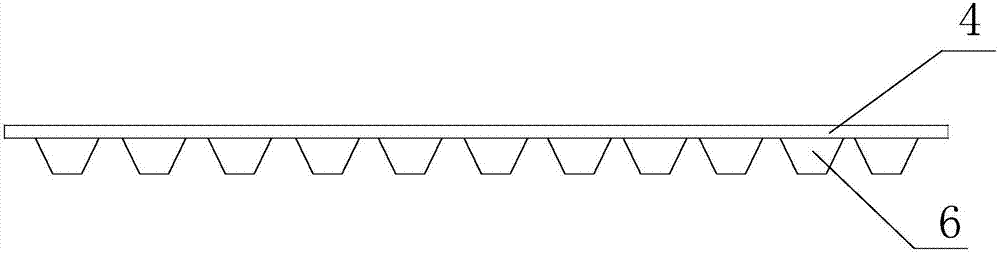

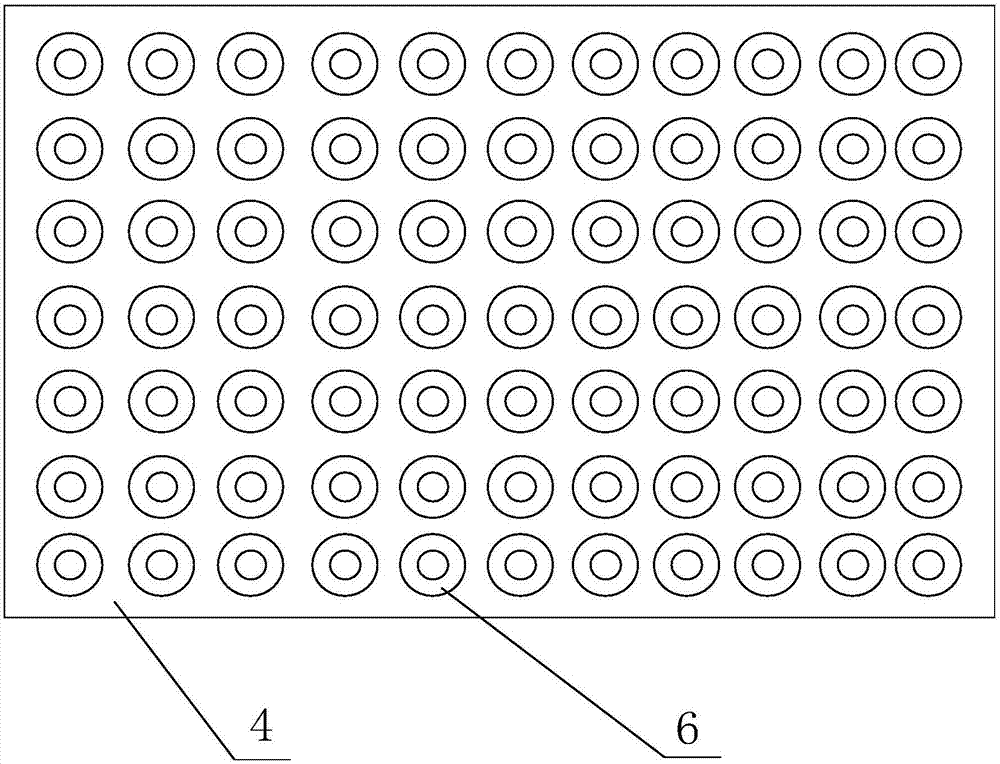

Moistureproof breathable ground mat

The invention discloses a moistureproof breathable ground mat. The moistureproof breathable ground mat is characterized in that the moistureproof breathable ground mat comprises an IXPE buffer layer (2) at the upper layer and a PE layer (4) at the lower layer, the bottom surface of the IXPE buffer layer (2) and the back surface of the PE layer (4) are bonded together through a bonding layer (3), the bonding layer (3) is provided with double faced adhesive tape, a plurality of circular truncated cones (6) are distributed on the front surface of the PE layer (4), the diameters of the top surfaces of the circular truncated cones (6) are 6-8 mm, the bottom surfaces of the circular truncated cones (6) are 14-16 mm, and the heights of the circular truncated cones (6) are 10-12 mm. The moistureproof breathable ground mat has good buffer and isolation functions and is breathable and moistureproof, floors can be effectively protected for a long time.

Owner:常州海辰装饰材料有限公司

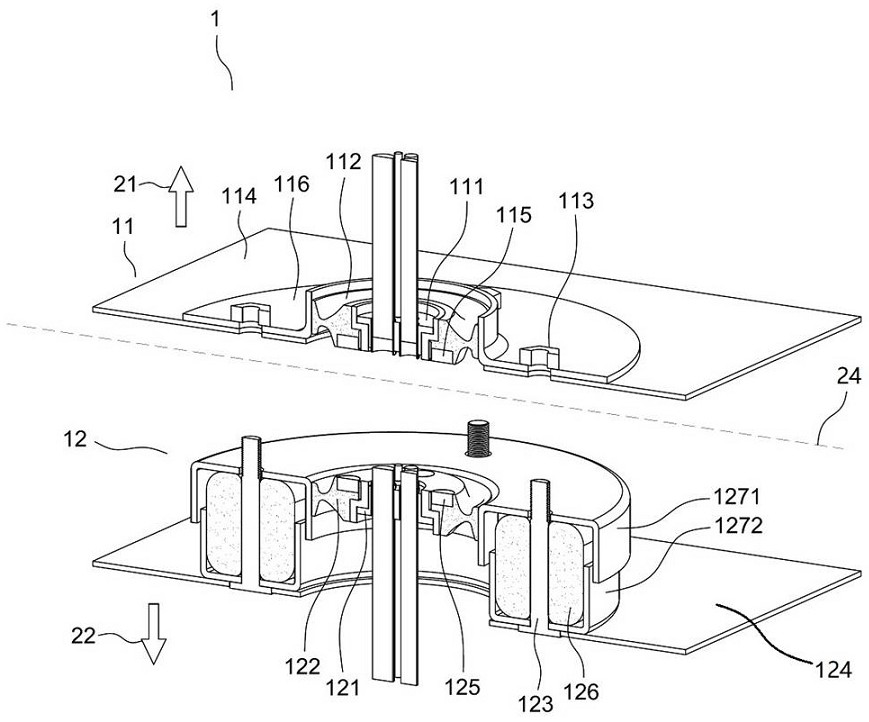

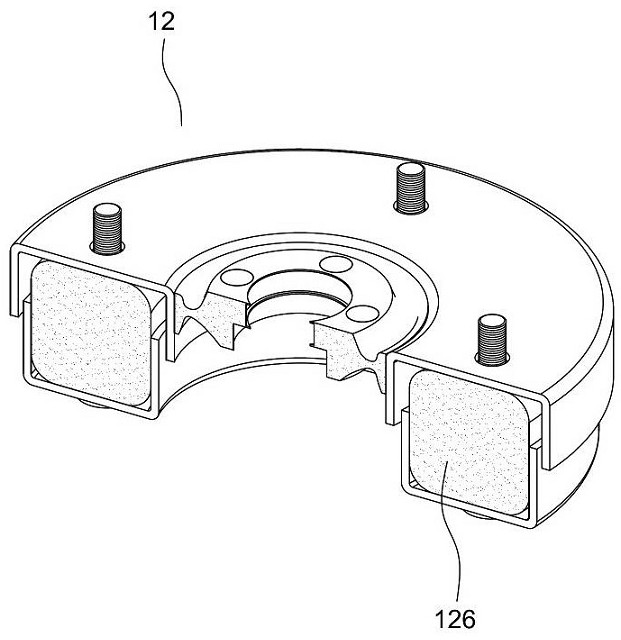

Mosaic joint structure and mobile carrier

ActiveCN112849277ALower center of gravityImprove stabilityEngagement/disengagement of coupling partsSuperstructure connectionsUpper jointStructural engineering

The invention discloses a mosaic joint structure which comprises an upper joint and a lower joint used for being connected to the upper joint, wherein the opposite faces of an upper joint elastic material seat and a lower joint elastic material seat abut against each other, an upper joint magnet and a lower joint magnet are mounted on the opposite surfaces of the upper joint elastic material seat and the lower joint elastic material seat, and an upper connector socket is connected with a lower connector socket. A shock insulation assembly is arranged between a shock insulation seat top cover and a rigid material seat annular bottom box, the shock insulation seat bottom box is fixed to a lower carrier bottom plate, and the shock insulation seat top cover abuts against an upper carrier bottom plate. The relative position relation of the upper carrier bottom plate and the lower carrier bottom plate is restrained through the fixing mode of an upper connector fixing piece and a lower connector fixing piece. The mosaic joint structure is provided with a structure capable of quickly connecting the electrical and entity line signals between an upper vehicle body and a lower vehicle body and damping.

Owner:METAL INDS RES & DEV CENT

Transfer device for machining

PendingCN112692805AAvoid collisions and scratchesEffective leapNon-rotating vibration suppressionWork tools storageEngineeringMachining

The invention discloses a transfer device for machining, which belongs to the technical field of machining and solves the problem that an existing transfer device for machining cannot be placed in a classified mode. The transfer device for machining is characterized by comprising a supporting plate, wherein a damping assembly is arranged at the bottom of the supporting plate, and a moving assembly is fixedly connected to the bottom of the damping assembly; a first placing plate is arranged above the supporting plate, supporting rods are symmetrically and vertically arranged above the first placing plate, second baffle plates are arranged in the middles of the supporting rods, a second placing plate is arranged on the outer sides of the supporting rods above the second baffle plates, a top plate is fixedly connected to the tops of the supporting rods, and a third placing plate is fixedly connected to the upper portion of the top plate. Parts are placed in a layered mode through the first placing plate, the second placing plate and the third placing plate, obstacles are conveniently crossed through the moving assembly, vibration borne by the device is weakened through the damping assembly, and thus, the transfer device has the advantages of being placed in a layered mode, flexible to move, effective in damping, simple, convenient to use and practical.

Owner:舒德祥

Electrolytic aluminum crown block control module additionally provided with UPS (Uninterrupted Power Supply)

PendingCN114726082APrevent shakingSimple structurePower network operation systems integrationSubstation/switching arrangement cooling/ventilationElectrical engineering technologyEngineering

The invention relates to the technical field of electrical engineering, and discloses an electrolytic aluminum crown block control module added UPS power supply, which comprises a base, a mounting groove is formed in the top of the base, a shell is arranged in the mounting groove, a mounting mechanism is fixedly connected to the right side of the shell, a damping mechanism is fixedly connected to the bottom in the shell, and the damping mechanism is fixedly connected to the bottom in the shell. A heat dissipation mechanism is arranged on the left side of the shell, a UPS is arranged in the shell, and a cover plate is hinged to the top of the shell through hinges. According to the electrolytic aluminum crown block control module, the UPS is additionally arranged, the mounting mechanism is arranged, the T-shaped blocks on the two sides of the shell are placed into the corresponding T-shaped grooves, then the movable blocks are pushed downwards until the clamping blocks enter the corresponding clamping grooves under the action of the first springs, mounting of the UPS is completed at the moment, and the mounting mechanism is simple in structure, convenient and rapid to operate and high in practicability. And through limiting from the bottom and the two sides of the shell, the phenomenon that the UPS shakes during use is prevented, and the practicability of the device is improved.

Owner:滨州市宏诺新材料有限公司 +1

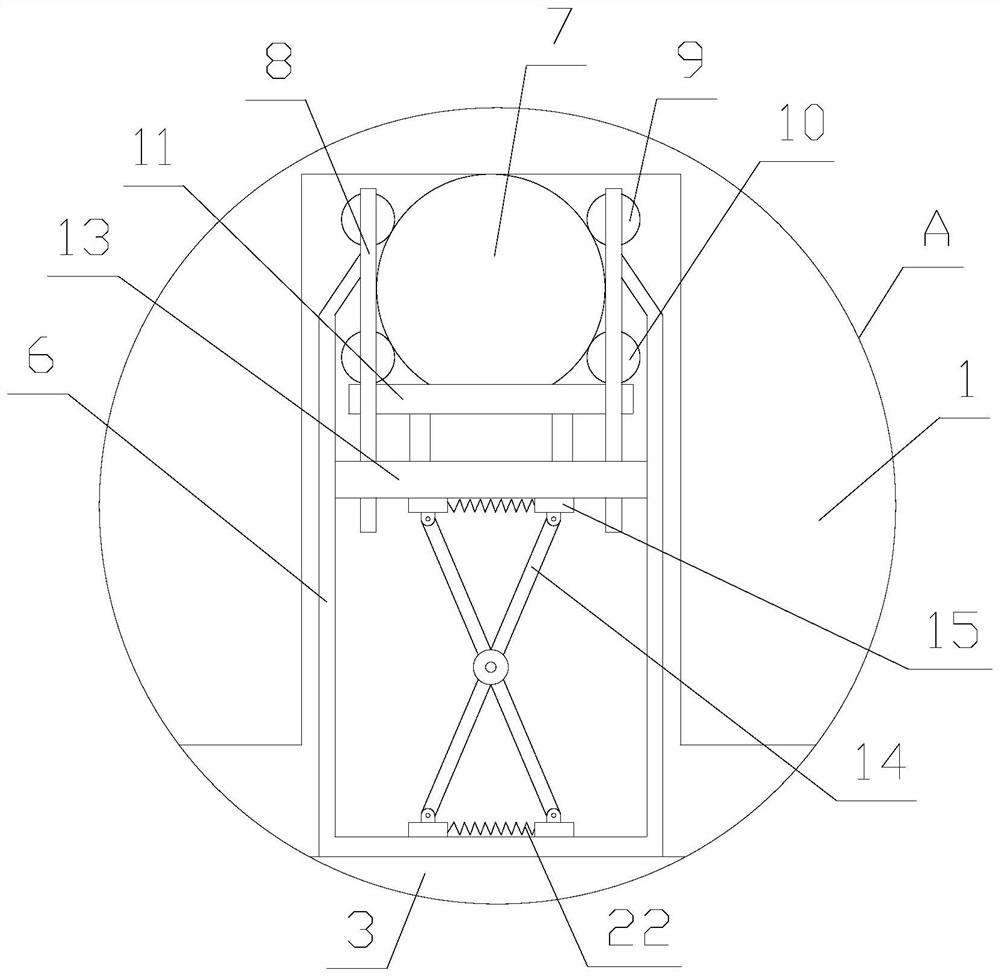

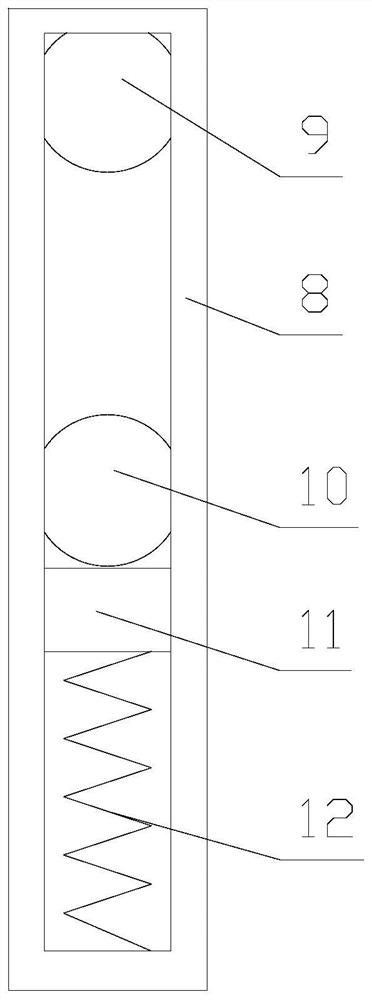

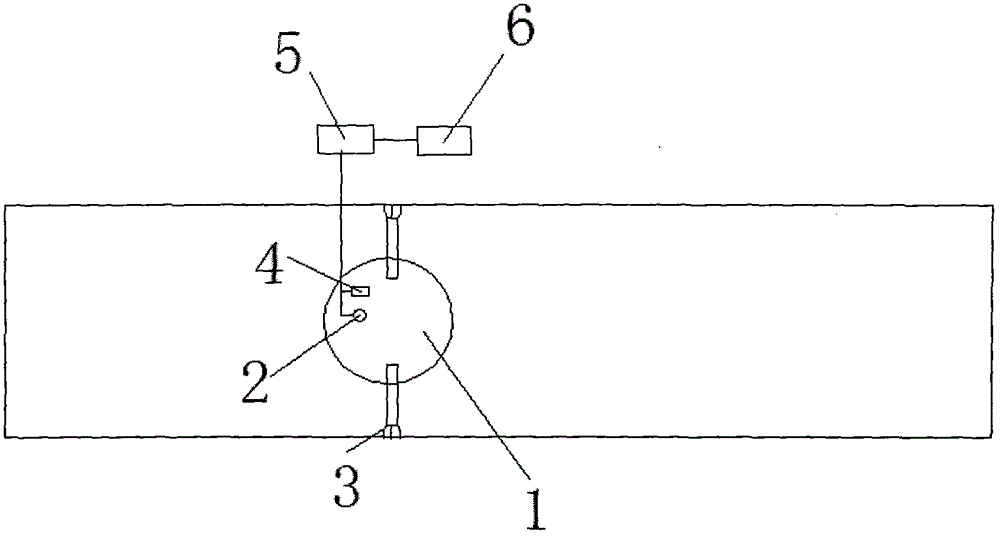

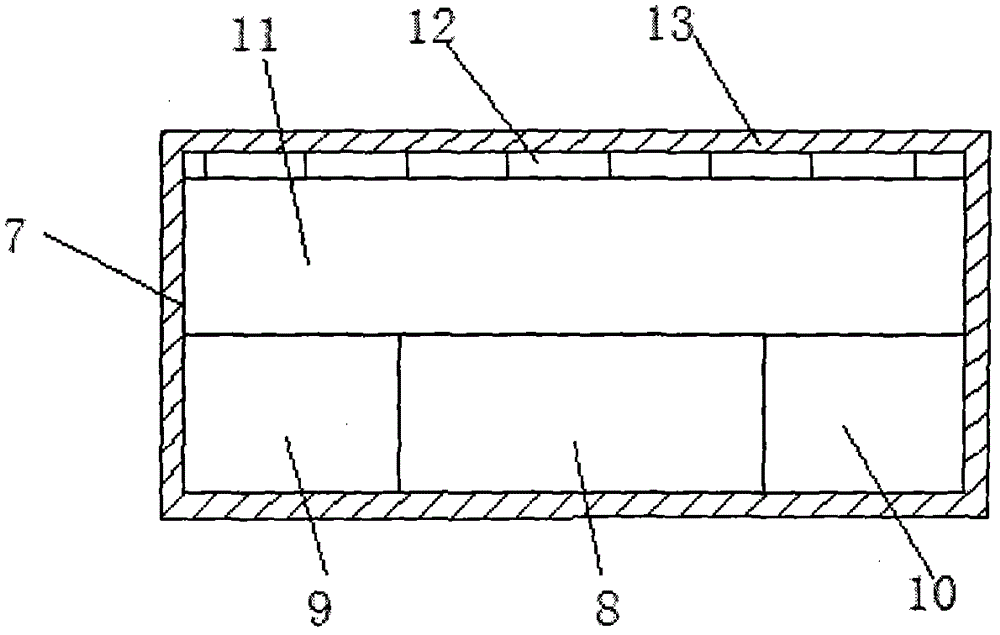

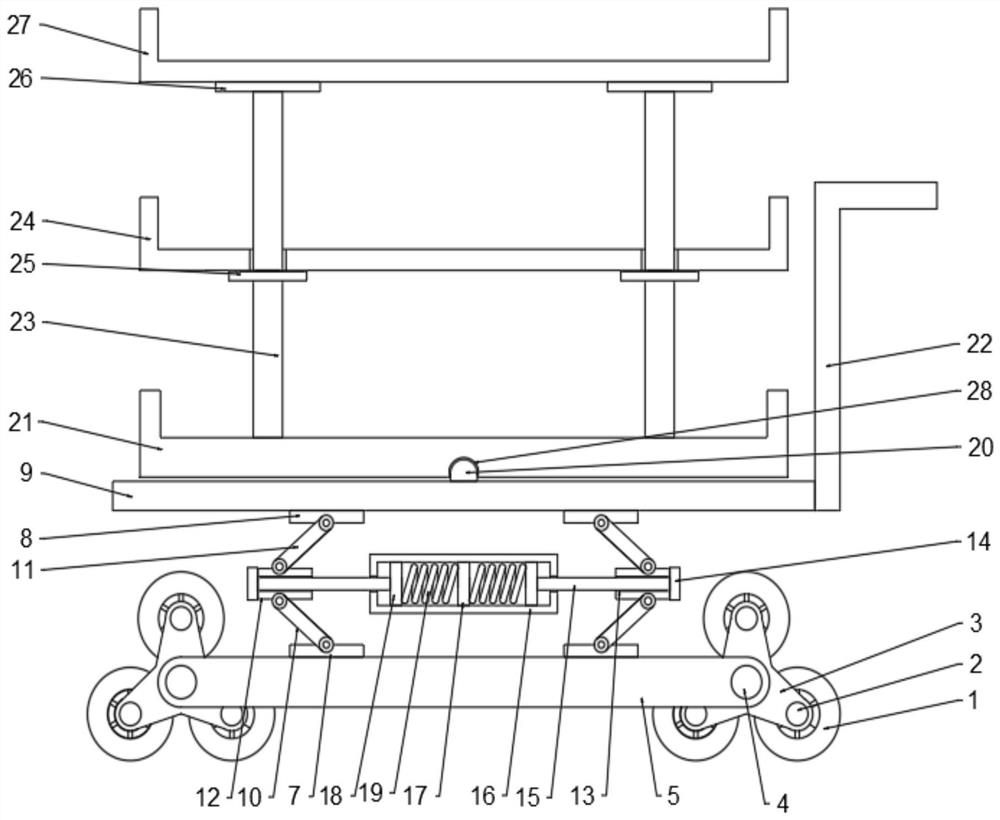

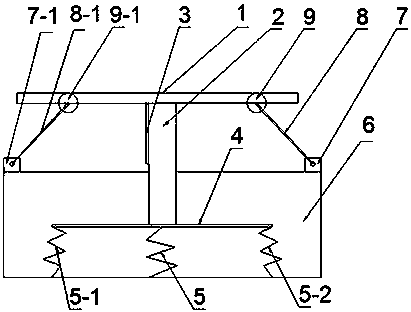

Damping device with combined spring and roller

PendingCN107630959AReduce hard requirementsExpand the available rangeShock absorbersEngineeringVibration source

The invention relates to the field of mechanical damping and discloses a damping device with combined springs and rollers. Vibration is conducted through a vibration sensing plate 1 from a vibration source, a vibration column 2 is driven to move downwards, the vibration is buffered through a damping plate 4 through a damping spring 5, a left damping spring 5-1 and a right damping spring 5-2, on the other hand, as the vibration sensing plate 1 is moved downwards, a right roller 9 and a left roller 9-1 are driven to slide on the vibration sensing plate 1, and thus the vibration is counteracted.Damping is achieved in two modes, the device is relatively efficient, and relatively rich types of damping materials can be selected.

Owner:成都大运汽车集团有限公司

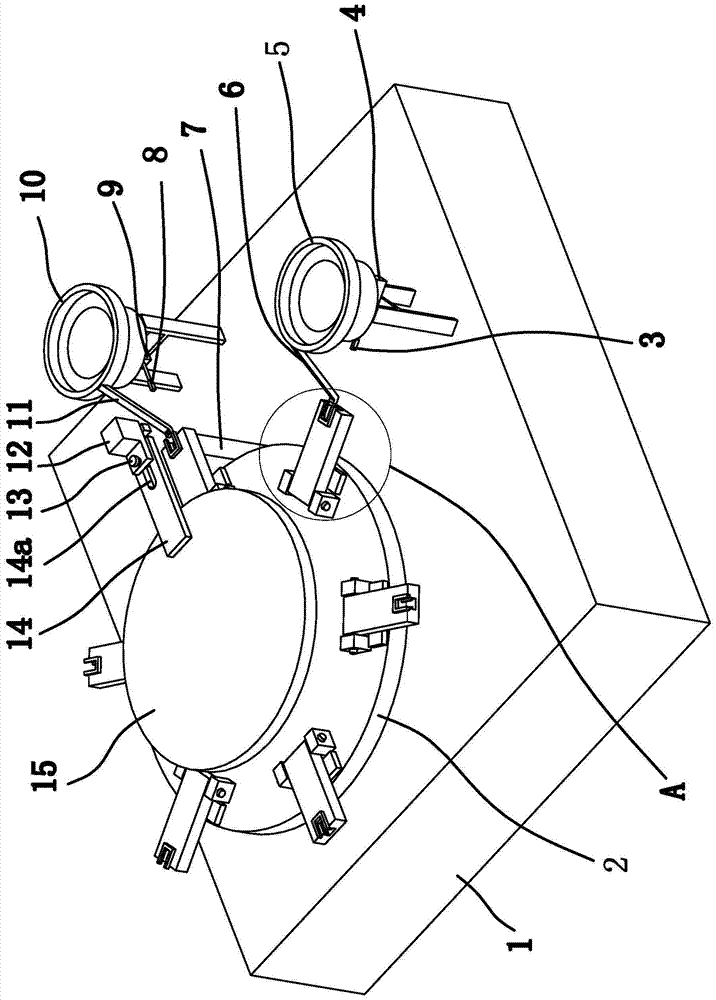

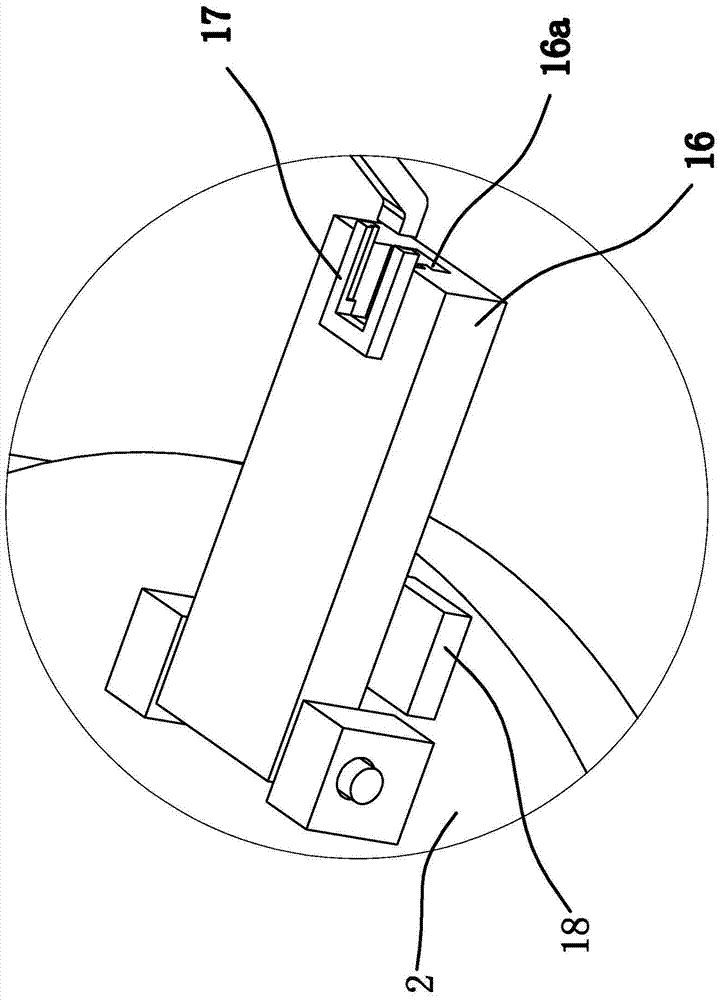

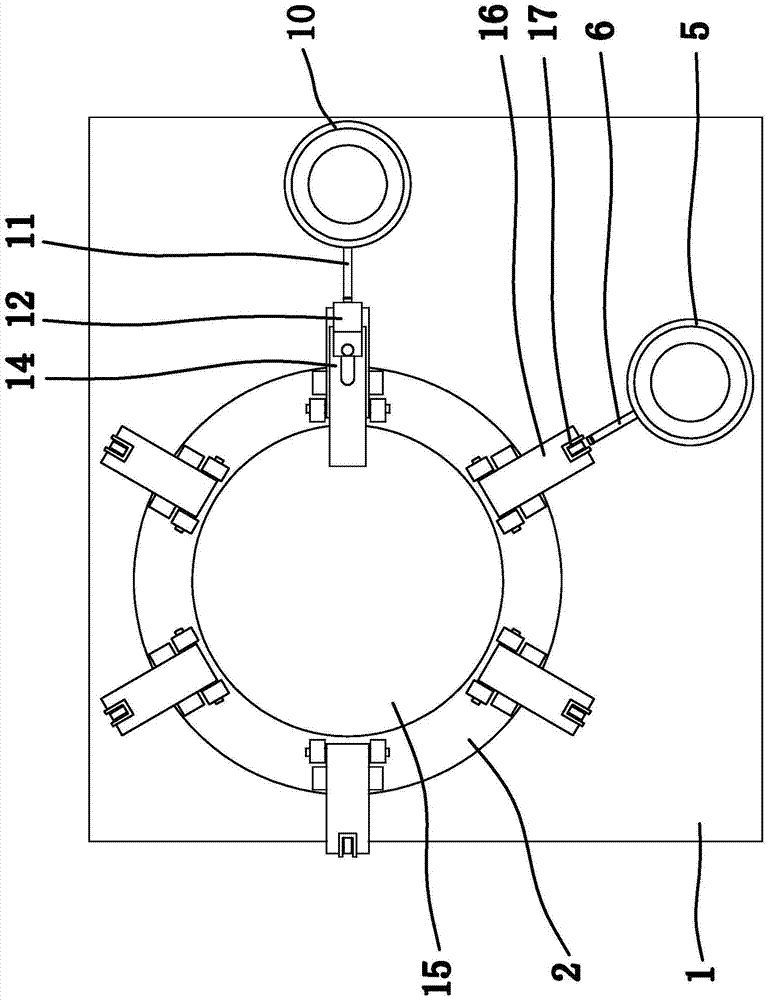

An assembly device for a slider in a zipper

InactiveCN104942164BRealize automatic loading operationContinuous uninterrupted assembly workSlide fastenersMetal-working feeding devicesEngineeringFastener

The invention provides an assembling device for pullers in zippers, and belongs to the technical field of machinery. By the aid of the assembling device, technical problems of low production efficiency, high labor intensity and the like due to the fact that assembling mechanisms in the prior art cannot be used for large-scale production operation and need to be manually operated can be solved. The assembling device for the pullers in the zippers comprises a framework, a fixing disc, a connecting rod, a turntable, a connecting barrel, a stamping assembly and a driving assembly. The upper end of the connecting rod is fixedly connected to the center of the fixing disc, a through hole is formed in the center of the turntable, the connecting rod penetrates the through hole in the turntable, the lower end of the connecting rod is fixedly connected onto the framework, the connecting barrel sleeves the connecting rod, the upper end of the connecting barrel is fixedly connected with the turntable, the lower end of the connecting barrel is connected with the driving assembly, a positioning mechanism capable of positioning a body is arranged at the edge of the turntable, and the stamping assembly is fixedly connected to the edge of the fixing disc and can be vertically aligned with the positioning mechanism after the driving assembly drives the turntable to intermittently rotate. The assembling device has the advantages of high assembling efficiency and good universality.

Owner:广州市正伟翔拉链有限公司

A hard disk video recorder with anti-shock device

ActiveCN103945155BIncrease elasticityGently eliminate vibrationTelevision system detailsUndesired vibrations/sounds insulation/absorptionCooling effectVibration isolation

The invention discloses a hard disk video with vibration isolation equipment. The hard disk video comprises a hard disk body, a shell and vibration isolation equipment, wherein the hard disk body is arranged in a hard disk holding cavity in a hard disk video case, the shell is arranged in the hard disk holding cavity so as to enclose the hard disk body, and the isolation equipment is arranged in the shell; the damping device comprises an upper end damping part and a lower end damping part, wherein the upper end damping part is a rectangular structural body and is respectively divided into a solid layer, a hollow layer and a raised layer from top to bottom, and the thickness proportion of the solid layer, the hollow layer and the raised layer is (1-2): (2-4): 1; the lower end damping part comprises two wedged structural bodies which are alternately arranged at the bottom of the hard disc body, and the axial directions of the wedge structural bodies and the axial direction of the hard disc body are arranged in parallel. The hard disk video with the vibration isolation equipment is simple in structure, good in vibration isolation effect, good in cooling effect and convenient to change a hard disk, so that the hard disk video can be applied to mass production.

Owner:哈威光电科技(苏州)有限公司

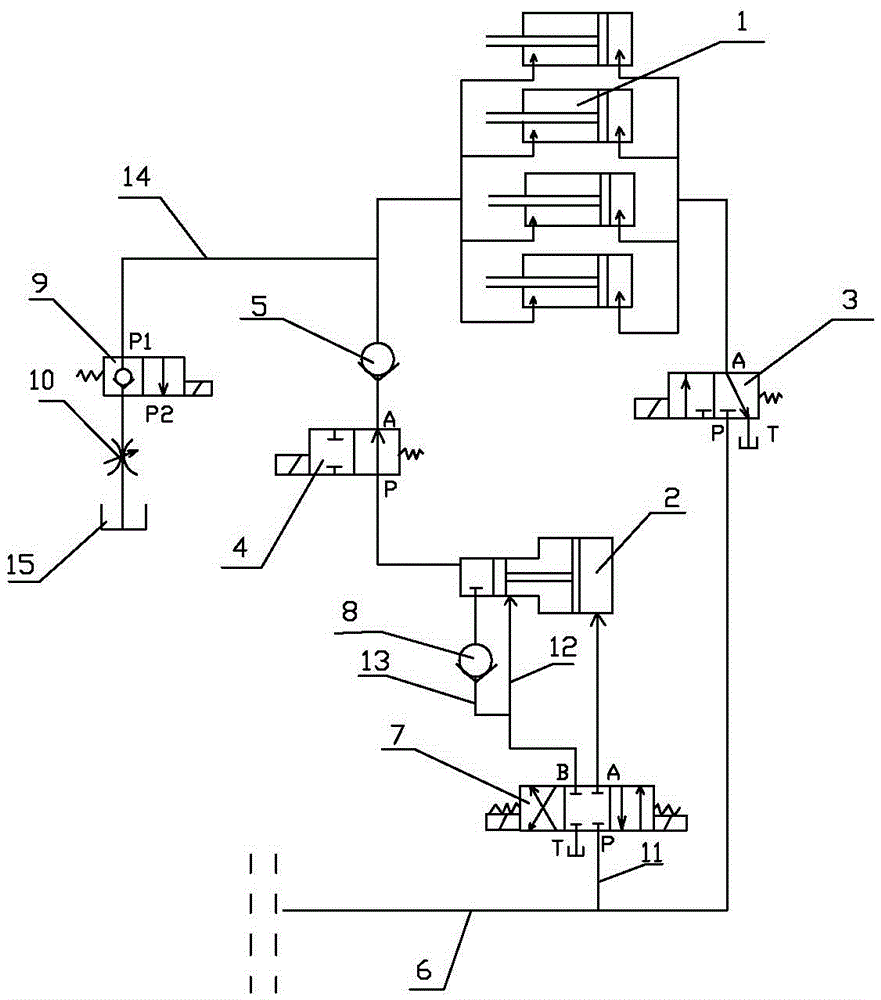

Two-platen hydraulic injection molding machine normal pressure, pressurized, high pressure mold clamping circuit

The invention discloses a two-platen hydraulic injection molding machine with normal pressure, boosted pressure and high pressure mold clamping circuit, including a mold clamping hydraulic cylinder, a booster hydraulic cylinder, a two-position three-way reversing valve, and a two-position two-way reversing valve of the mold clamping oil circuit And clamping oil circuit check valve, characterized in that: the pressure oil pipe is connected to the pressure side oil port P of the three-position four-way reversing valve through the first branch pressure oil pipe, and the right end of the three-position four-way reversing valve The side oil port A is connected to the oil port of the rodless chamber of the large oil cylinder of the pressurized hydraulic cylinder; the upper oil port B on the left end of the three-position four-way reversing valve is connected with the rod chamber of the small oil cylinder of the pressurized hydraulic cylinder through a connecting oil pipe At the same time, the oil port B on the left end of the three-position four-way reversing valve is also communicated with the rodless cavity of the small oil cylinder of the pressurized hydraulic cylinder through the second branch oil pipe. This circuit is simple in structure, easy to operate, and has two functions of normal pressure mold clamping and high pressure mold clamping. It can not only realize mold clamping, but also slow down the impact buffer on the contact surface of the mold through normal pressure mold clamping, so as to achieve the initial stability of the mold clamping process. Require.

Owner:山东胜沃塑料机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com