Mosaic joint structure and mobile carrier

A joint structure and vehicle technology, which is applied in the connection and connection between the superstructure and the superstructure sub-assemblies, can solve the problems of poor vibration isolation effect and noise, reduce the center of gravity of the whole vehicle, reduce the difficulty, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the above objects, features and features of the present invention more comprehensible, the relevant embodiments of the present invention are described in detail as follows with reference to the accompanying drawings.

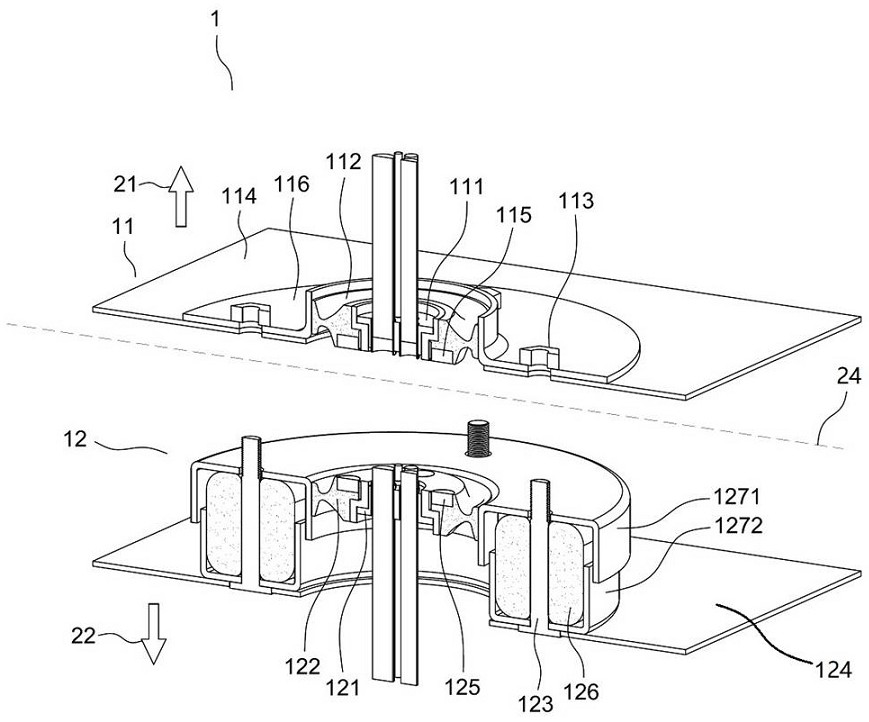

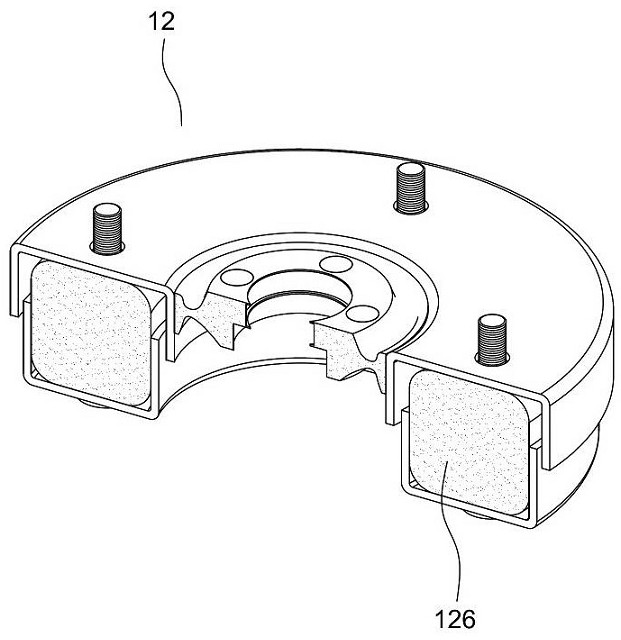

[0055] figure 2 It is an exploded perspective view of an upper joint and a lower joint of a mosaic joint structure according to an embodiment of the present invention. Please refer to figure 2 , the mosaic joint structure 1 includes an upper joint 11 and a lower joint 12 . The upper connector 11 includes an upper connector socket 111 , an upper connector elastic material seat 112 , an upper connector fixing member 113 , an upper carrier base 114 , an upper connector magnet 115 and an annular upper plate 116 . The upper joint elastic material seat 112 overlaps the upper joint socket 111 , the annular upper plate 116 overlaps the upper carrier bottom plate 114 , and the annular upper plate 116 surrounds and adheres to the upper joint el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com