Transfer device for machining

A transfer device and mechanical processing technology, applied in the field of mechanical processing, can solve problems such as difficult promotion and application, scratches and collisions of parts, and inability to classify and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

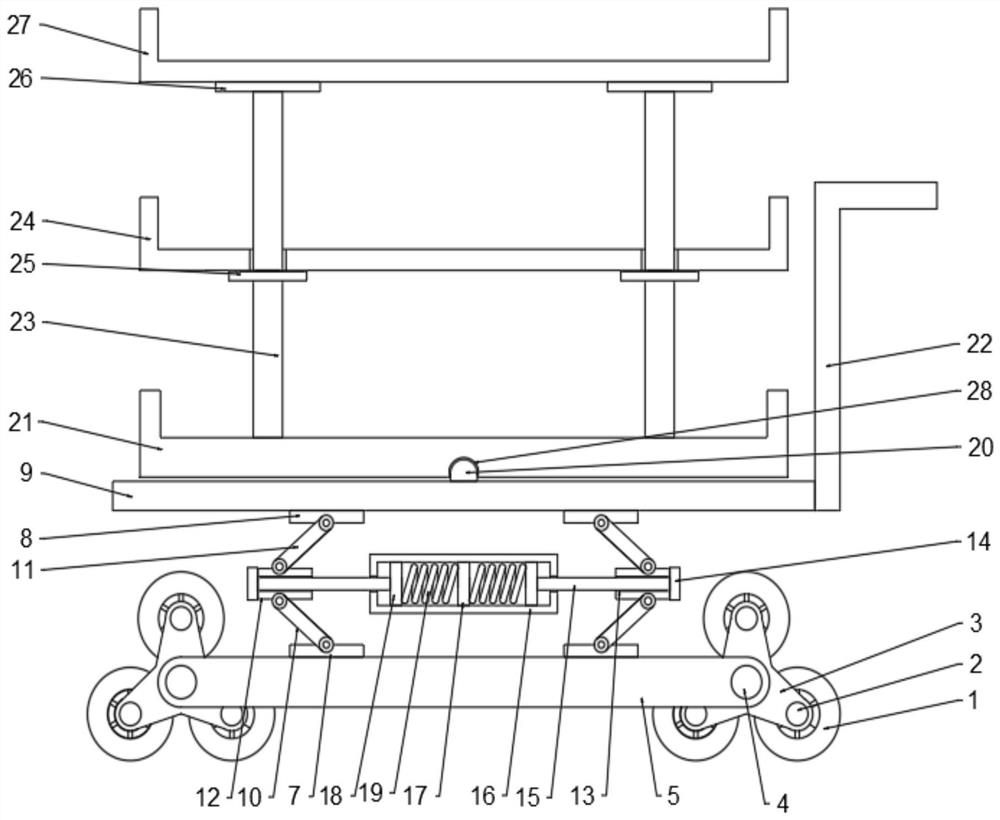

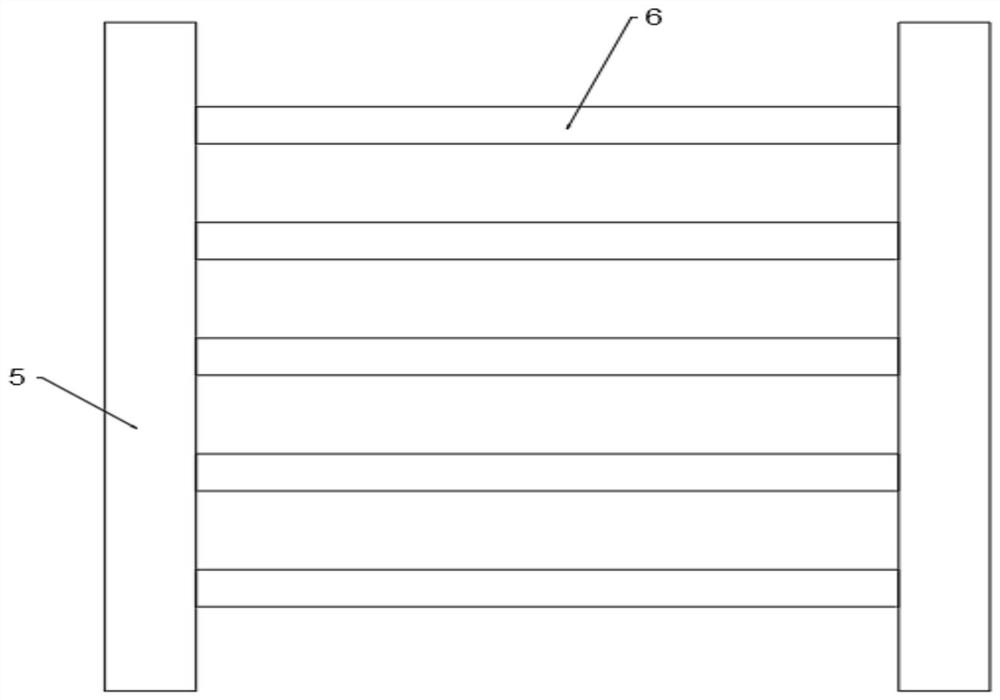

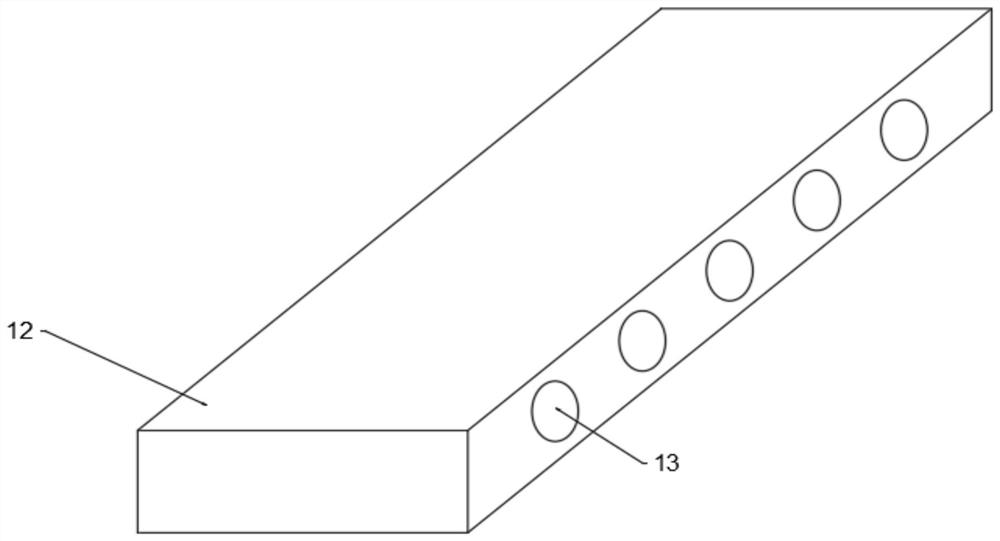

[0025] see Figure 1 ~ Figure 3 , a transfer device for mechanical processing, comprising a support plate 9, a shock absorbing assembly is provided at the bottom of the support plate 9, a moving assembly is fixedly connected to the bottom of the shock absorbing assembly, and a first placement plate is provided above the support plate 9 21. A central rotating rod 20 is fixedly arranged at the center above the support plate 9, and a rotating hole 28 cooperating with the central rotating rod 20 is provided at the bottom of the first placing plate 21. There is a support rod 23, the middle part of the support rod 23 is provided with a second baffle plate 25, the outside of the support rod 23 above the second baffle plate 25 is provided with a second placement plate 24, and the top of the support rod 23 is fixedly connected with Top plate 26, the third placement plate 27 is fixedly connected above the top plate 26, through the first placement plate 21, the second placement plate 24 ...

Embodiment 2

[0031] see Figure 1 ~ Figure 4 , such as a transfer device for mechanical processing in Example 1, including a support plate 9, the bottom of the support plate 9 is provided with a shock absorbing assembly, the bottom of the shock absorbing assembly is fixedly connected with a moving assembly, and the top of the support plate 9 A first placing plate 21 is provided, and a central rotating rod 20 is fixedly arranged at the center above the support plate 9, and a rotating hole 28 cooperating with the central rotating rod 20 is provided at the bottom of the first placing plate 21, and the first placing The top of the plate 21 is symmetrically and vertically provided with a support rod 23, the middle part of the support rod 23 is provided with a second baffle plate 25, and the outside of the support rod 23 above the second baffle plate 25 is provided with a second placement plate 24. The top of the rod 23 is fixedly connected with a top plate 26, and the top of the top plate 26 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com