Method for producing semi-tempered glass

A production method and semi-tempered technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as unsatisfactory glass flatness, energy consumption, and unstable operation process, so as to avoid collisions, scratches, and operation Flexible, process-stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 glass thickness is the production of semi-tempered glass of 8mm

[0047] Place the glass horizontally on the roller table, send it to the tempering furnace through the roller table, and then heat the glass to 700°C for 320s;

[0048] The heated glass is conveyed to the quenching zone through the roller table, the glass is placed horizontally on the roller table, and quenched for 300s under the wind pressure of 200Pa;

[0049] Cool the quenched glass under 350Pa wind pressure for 30s; then adjust the height of the upper air grille to 35mm and the lower air grille height to 40mm, and then cool it under 3000Pa wind pressure for 160s. Output the semi-tempered glass finished product with a thickness of 8mm.

Embodiment 2

[0051] Place the glass horizontally on the roller table, send it to the tempering furnace through the roller table, and then heat the glass to 690°C for 400s;

[0052] The heated glass is conveyed to the quenching zone through the roller table, the glass is placed horizontally on the roller table, and quenched for 390s under the wind pressure of 80Pa;

[0053] Cool the quenched glass under 100Pa wind pressure for 50s; then adjust the height of the upper air grille to 48mm and the lower air grille height to 40mm, and then cool it under 3000Pa wind pressure for 200s. Output the semi-tempered glass finished product with a thickness of 10mm.

Embodiment 3

[0055] Place the glass horizontally on the roller table, send it to the tempering furnace through the roller table, and then heat the glass to 680°C for 480s;

[0056] The heated glass is conveyed to the quenching zone through the roller table, the glass is placed horizontally on the roller table, and quenched for 600s under the wind pressure of 35Pa;

[0057] Cool the quenched glass under 50Pa wind pressure for 50s; then adjust the height of the upper air grille to 50mm and the height of the lower air grille to 30mm, and then cool it under 2000Pa wind pressure for 360s. Output the semi-tempered glass finished product with a thickness of 12mm.

[0058] It should be noted that the process parameters in the embodiments may vary according to the temperature and density of the airflow.

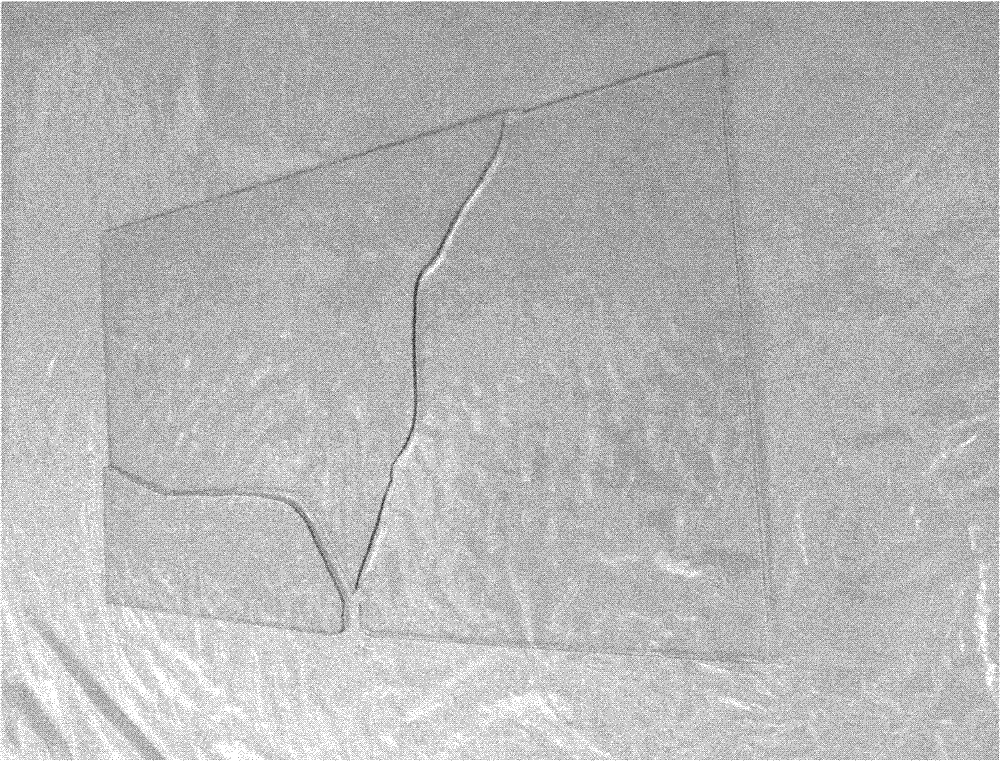

[0059] figure 1 It is the picture after cracking of semi-tempered glass produced by the method of the present invention. As shown in the figure, there is no tangential crack expansion when the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com