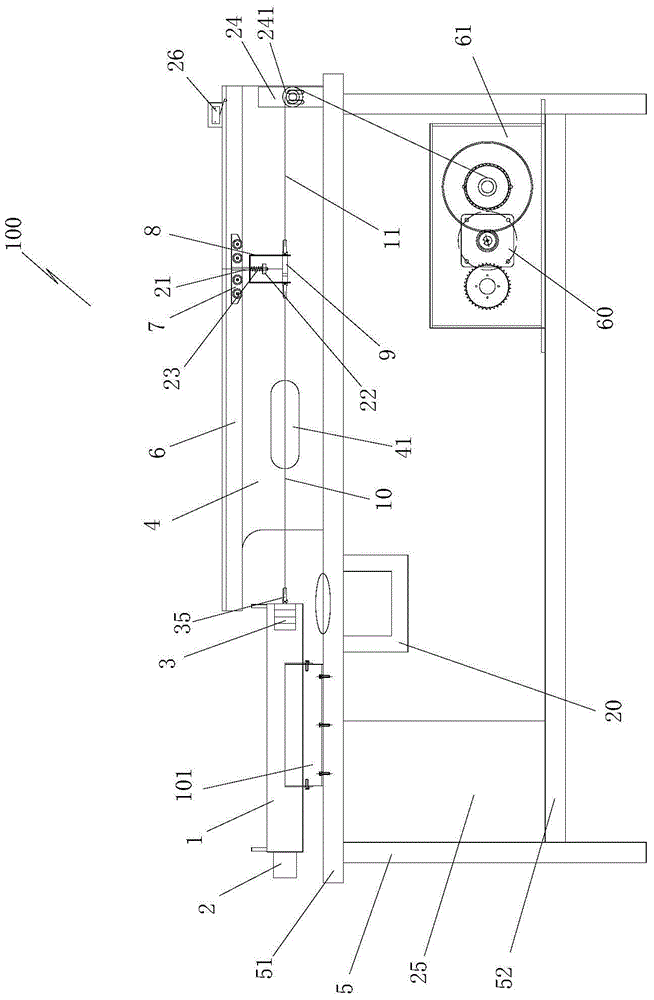

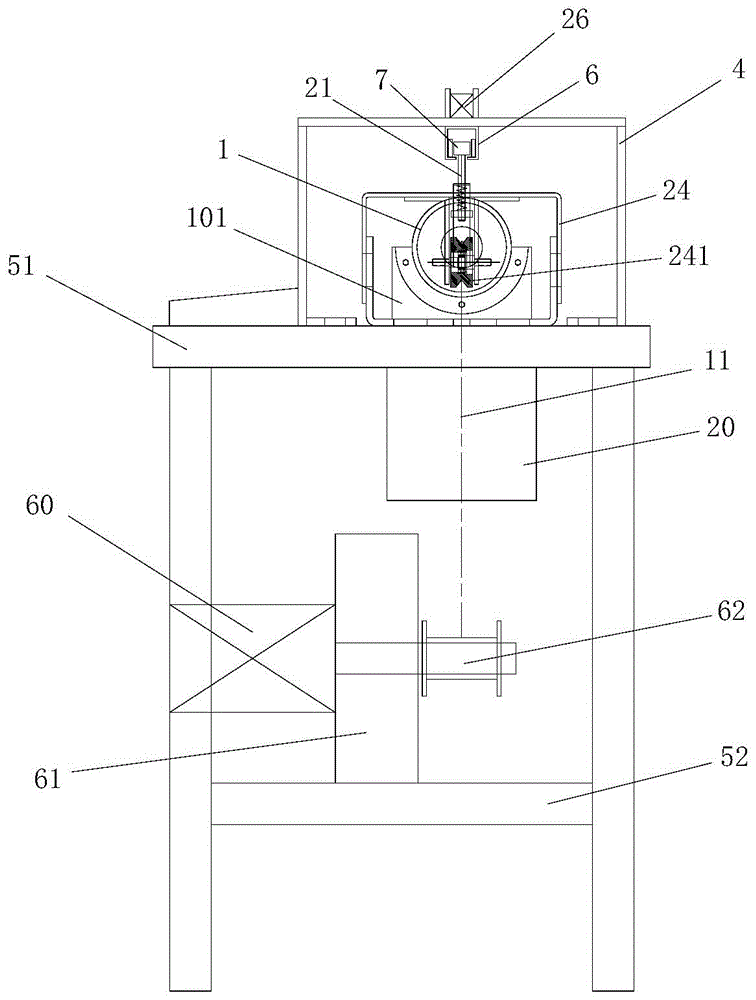

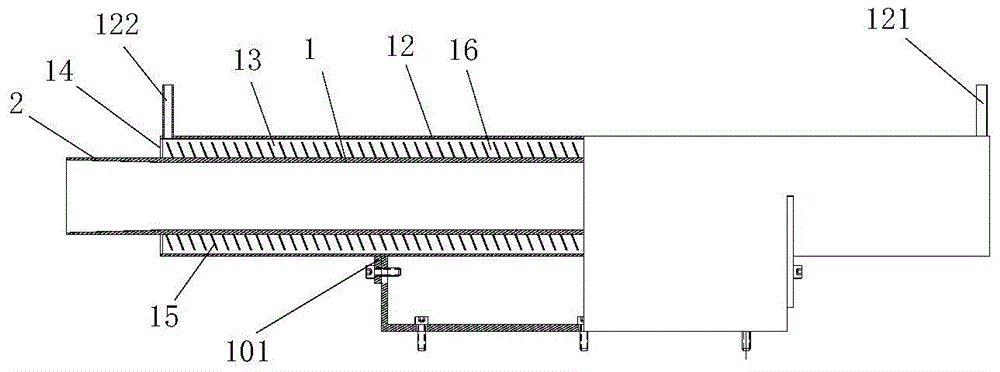

Crude oil pipeline ball passing and wax removal simulation experiment device and experiment method

A technology for simulating experimental devices and pipelines, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., and can solve problems such as peeling off of wax deposits on pipe walls that have not been involved in the strength of wax deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0072] Experimental conditions: dish-shaped double cup equal diameter pipe cleaner (Shore A hardness 85); 50% blending mass ratio of prepared wax deposits; experimental temperature 10°C; wax layer thickness 2, 4, 6mm. The wax layer resistance corresponding to the first short yield stage of the wax removal resistance curve obtained in this experiment is the wax layer destructive force corresponding to the thickness of the wax layer. The experimental results are shown in Table 1:

[0073] Table 110 ℃ wax removal test results

[0074]

[0075] It can be seen from Table 1 that the destructive force of the wax layer under 2, 4, and 6mm is different, but the strength of the wax layer is the same. This shows that the strength of the wax layer is only related to the characteristics of the wax layer (such as wax content) and has nothing to do with the thickness of the wax layer. The average value is 191511.6Pa. This value can be defaulted to be the intensity of the measured 50% blending ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com