Long conveying pipeline construction method capable of simultaneously clearing pipe and testing pressure

A technology for long-distance pipelines and construction methods, which can be used in cleaning methods and appliances, pipeline laying and maintenance, chemical instruments and methods, etc., and can solve problems such as water waste and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

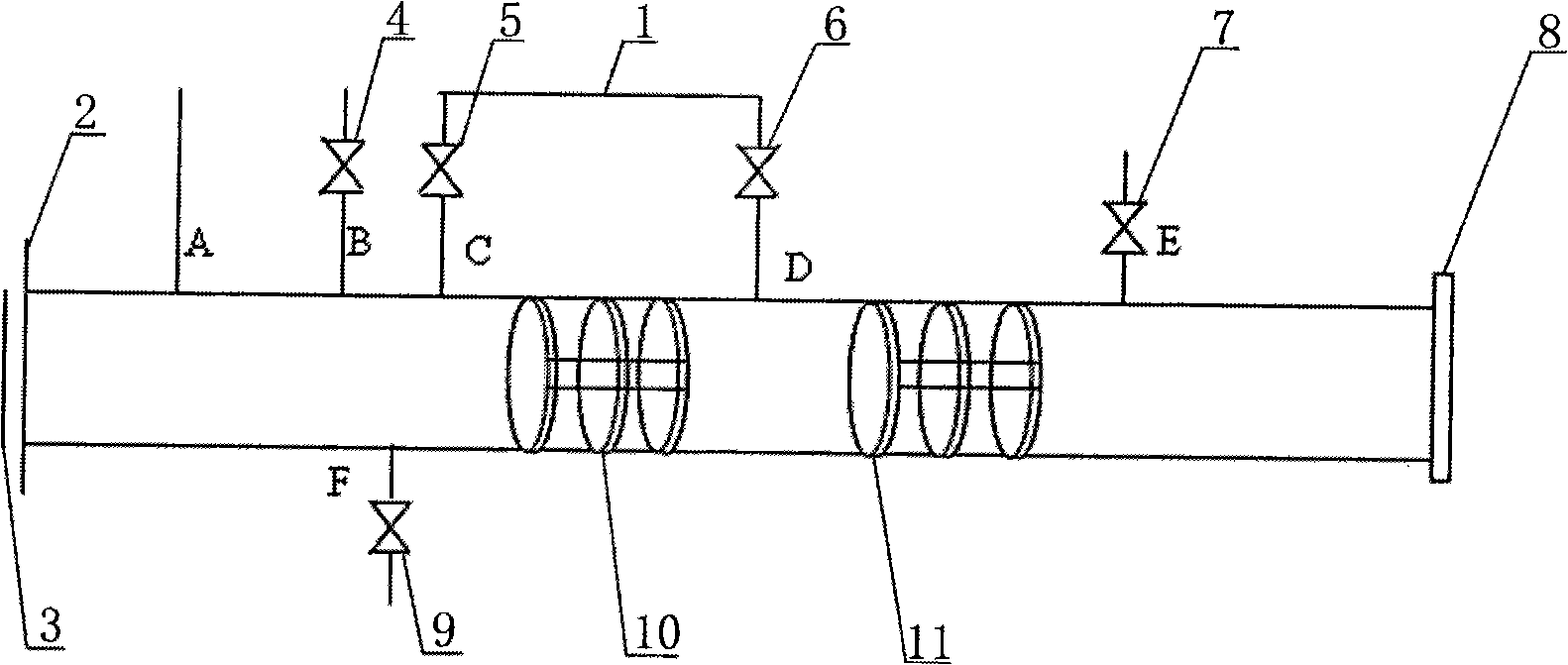

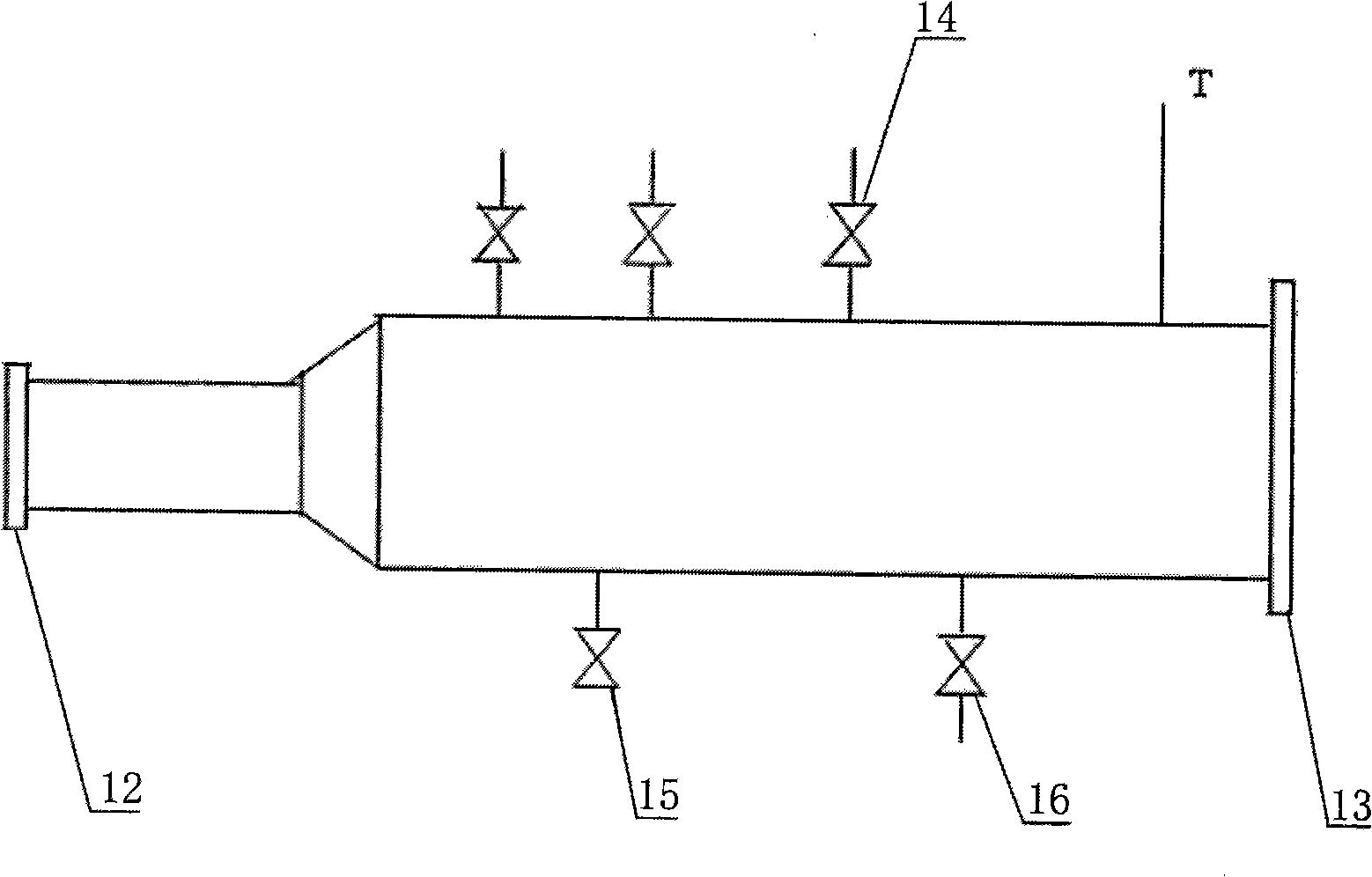

[0016] Process flow of the present invention:

[0017] Determining the overall pressure test plan--construction preparation--making of temporary pigging and pressure test facilities-----pigage and water injection for pressure test--boosting-----strength test-- ---Tightness test-----Pressure relief and drainage-----Pneumatic ball drainage.

[0018] Concrete method steps of the present invention and process parameters in the process thereof:

[0019] 1. Construction procedure:

[0020] Determine the overall pressure test plan-preparation work-making of temporary pigging and pressure test facilities-pigging and pressure test water injection-boosting-strength test-tightness test-pressure relief drainage-air pressure ball drainage.

[0021] 2. Construction principles:

[0022] The lower end of the pipeline is used as the water inlet point for the pigging pressure test, and the higher end is the ball receiving end of the pipeline. Pipe pigging and pressure test water injection a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com