High-speed rotating brush pipe cleaner

A high-speed rotation and pigging technology, which is applied in the pigging field of petroleum, fluid conveying pipelines, and natural gas pipelines, can solve the problems of low pigging efficiency and poor pigging effect, achieve sufficient mixing, fine particles, and improve pigging quality effect on efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

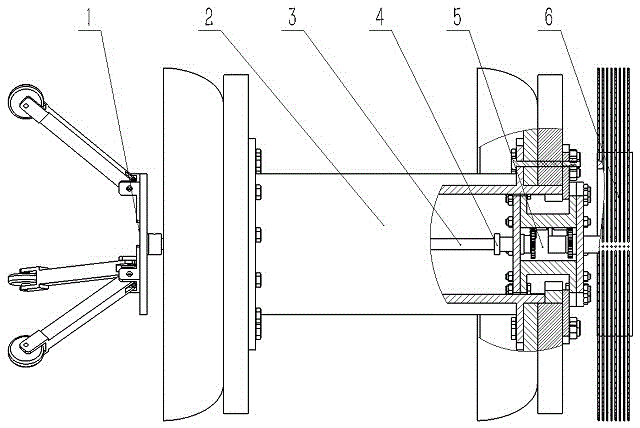

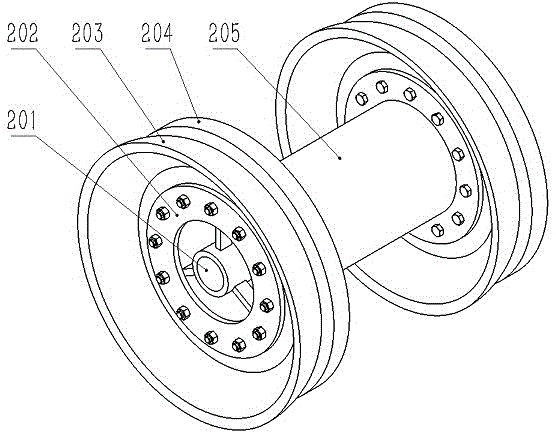

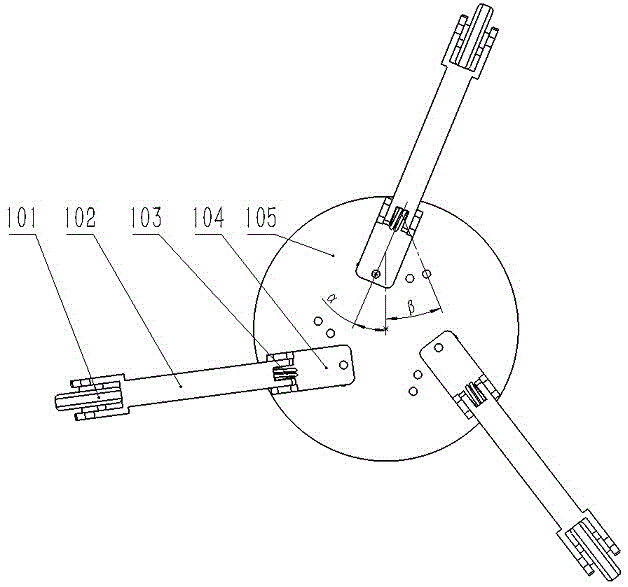

[0019] Such as figure 2 As shown, the pig supporting body 2 is composed of a rotating shaft mounting seat 201 , a flange 202 , a sealing cup 203 , a supporting cup 204 , and a skeleton 205 . A sealing cup 203 and a guide cup 204 are installed at the front and rear ends of the framework 205, and are fixed with a flange 202. The rotating shaft mounting seat 201 is installed in the draw-in groove at the rear end of the skeleton 205, and is compressed and fixed by the flange 202. Such as figure 1 As shown, the rotating mechanism 1 is installed at the rear end of the pig supporting body 2, the cleaning brush 6 is installed at the front end of the pig supporting body 2, the planetary gear transmission 5 is installed inside the pig supporting body 2, the rotating mechanism 1, the rotating shaft 3 , planetary gear transmission 5, cleaning brush 6 are connected successively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com