Ultralow-pressure well leakage plugging method

A plugging method and ultra-low pressure technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of cement pipe strings stuck in the wellbore, unable to achieve effective plugging, and cement slurry Leakage and other problems, to achieve the effect of guaranteed construction quality, improved pressure bearing capacity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

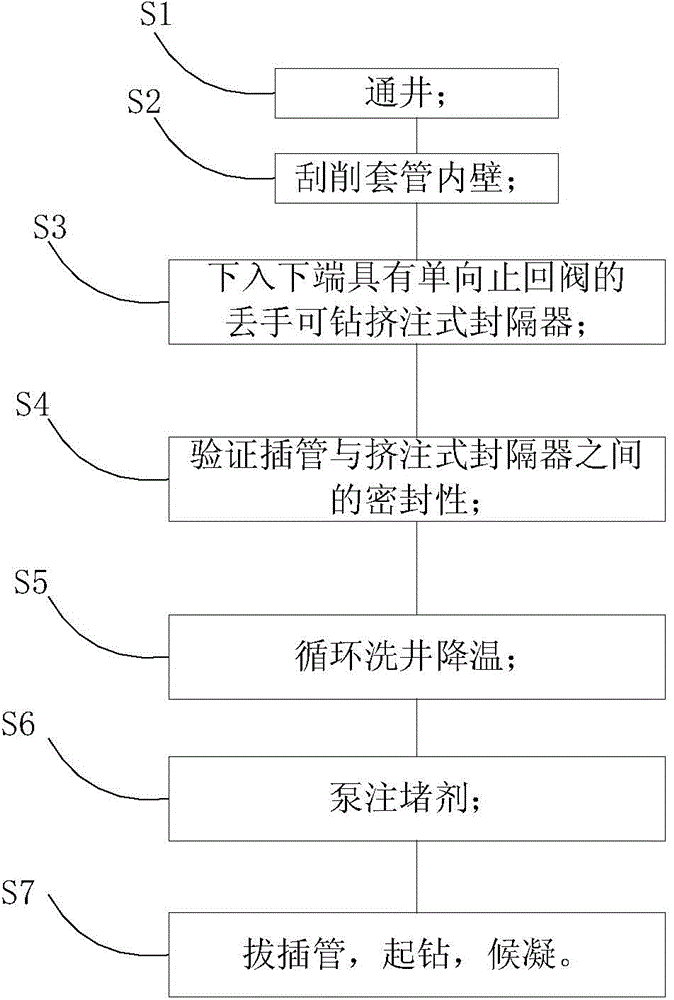

[0023] Embodiment 1: as figure 1 , figure 2 As shown, a plugging method for ultra-low pressure wells in oilfields can effectively reduce the large loss of working fluid, reduce the incidence of engineering accidents, and have a high plugging success rate.

[0024] The ultra-low pressure well plugging method includes the following steps:

[0025] a. After selecting a perforated well section as the entrance of cement slurry, set a squeeze packer in the upper casing of the perforated well section. return valve;

[0026] b. Lower the squeeze string, insert the cannula at the lower end of the squeeze string into the socket of the packer, so as to seal the gap between the string and the squeeze packer, and prevent the plugging agent from returning to the squeeze during plugging construction. Injection packer caused engineering accidents;

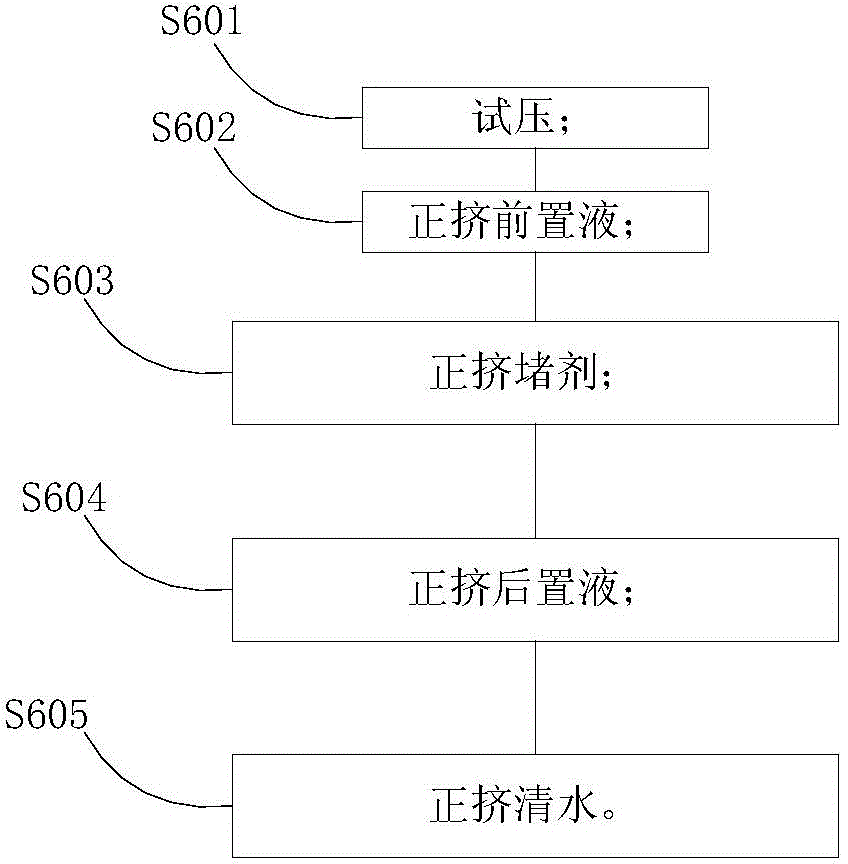

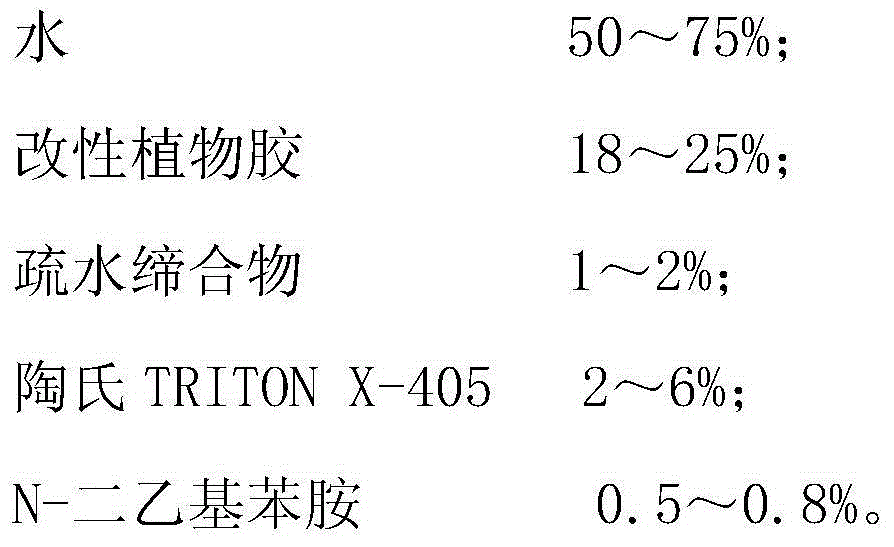

[0027] c. First pump the gel spacer fluid into the squeeze string, then pump the cement slurry, and finally pump the gel spacer fluid, squee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com