Laminated board fin structured heat exchanger with medium equipartition device

A technology of equalizers and laminated plates, which is applied in the direction of heat exchanger shells, indirect heat exchangers, heat exchanger types, etc., can solve problems such as uneven distribution, small refrigerant flow rate, and low evaporation efficiency, and achieve cost reduction. Low, good sealing effect, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

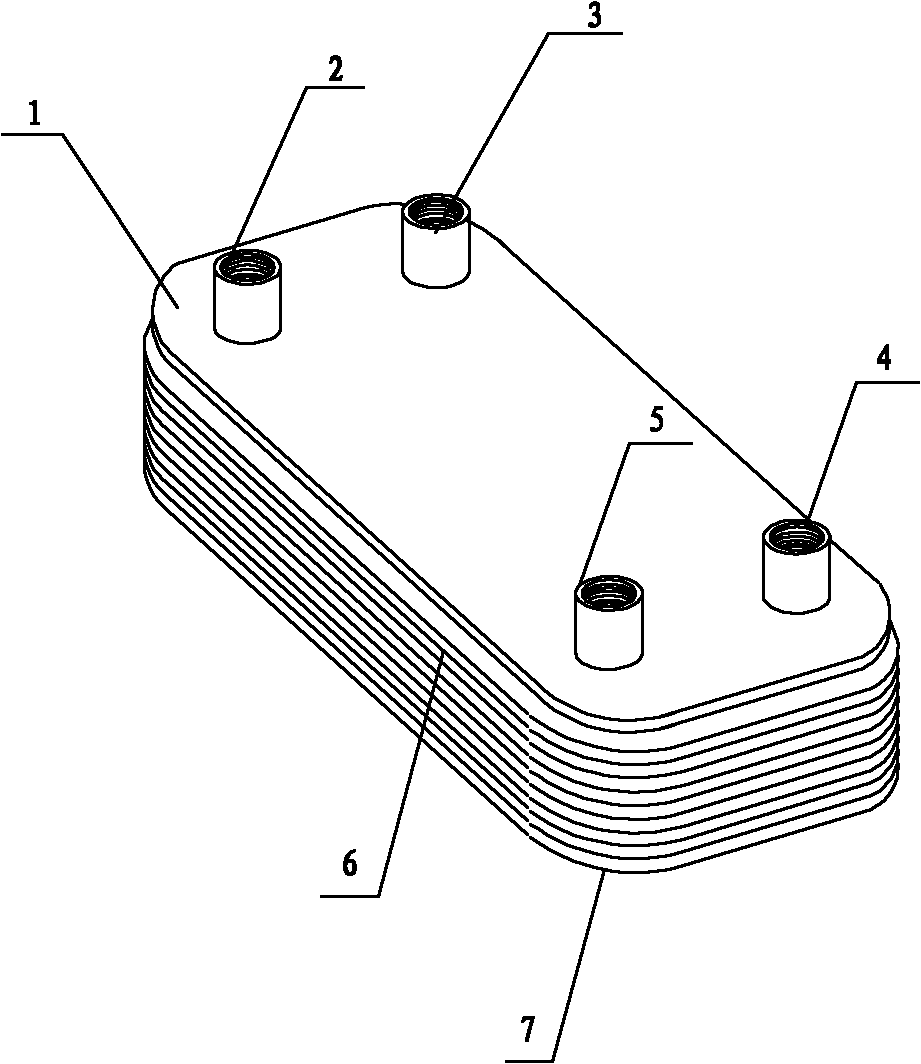

[0029] Refer to attached figure 1 , 3, 7, 9, the laminated plate-fin structure heat exchanger with medium divider is composed of upper cover plate 1, medium

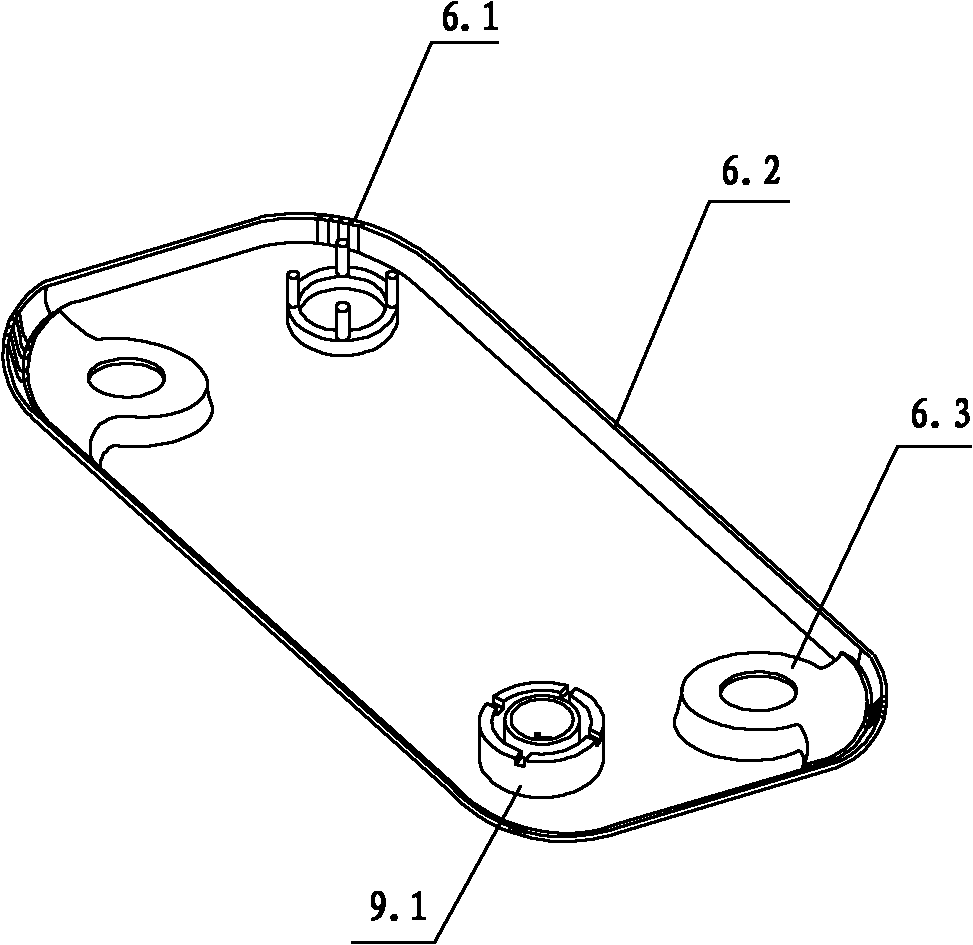

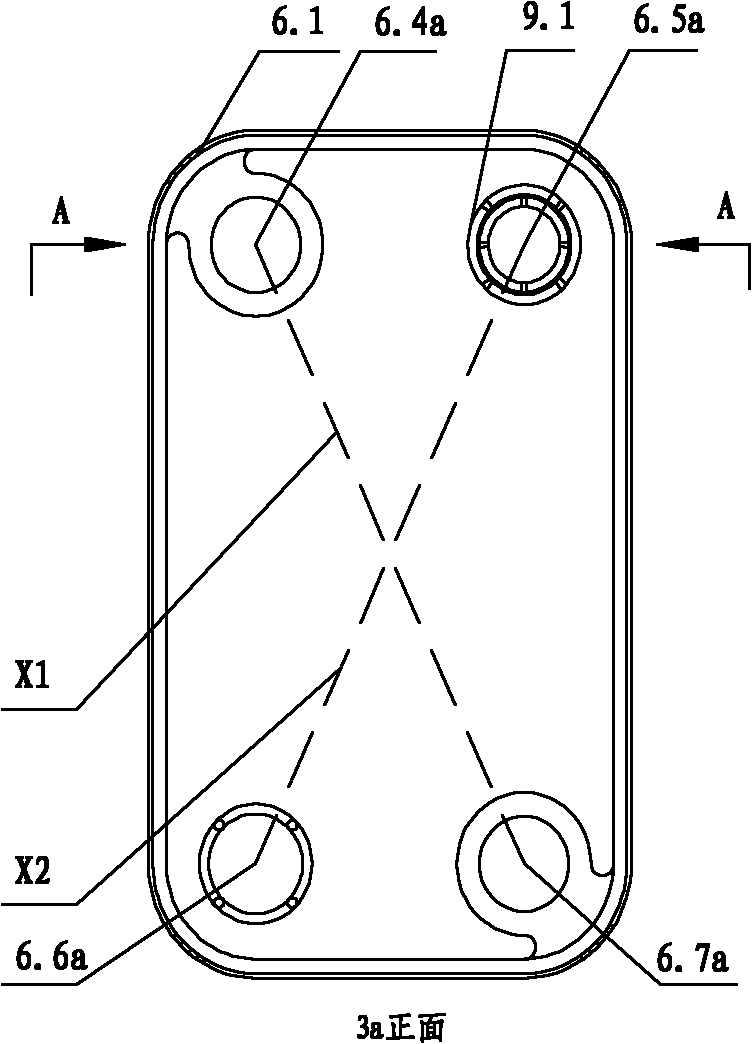

[0030] 1 inlet joint 2, medium 2 outlet 3, medium 2 inlet 4, medium 1 outlet 5, at least two partitions 6a and 6b, lower cover 7, at least two fins 8a and 8b, equalizer 9.1, ring top Column 9.2. The equalizer 9.1 is set on the low plane 11 of the partition 6, and the low plane 11 at the other end of the diagonal line X1 is an annular top column 9.2, and the medium inlet and outlet connecting pipes 2, 3, 4, 5 are respectively set on the upper cover plate 1 above. The flanging at four corners on the dividing plate 6 has anti-wrinkle incision 6.1.

[0031] Refer to attached Figure 3A , 3B with Figure 4A , 4B As shown, the separators 6a, 6b are punched into a disk-shaped structure, and the four sides of the separators 6a, 6b are provided with folded edges 6.2 extending upward from the low plane, and the angle betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com