Double-fluidized bed adsorption and desorption device and method for continuous treatment of organic waste gas

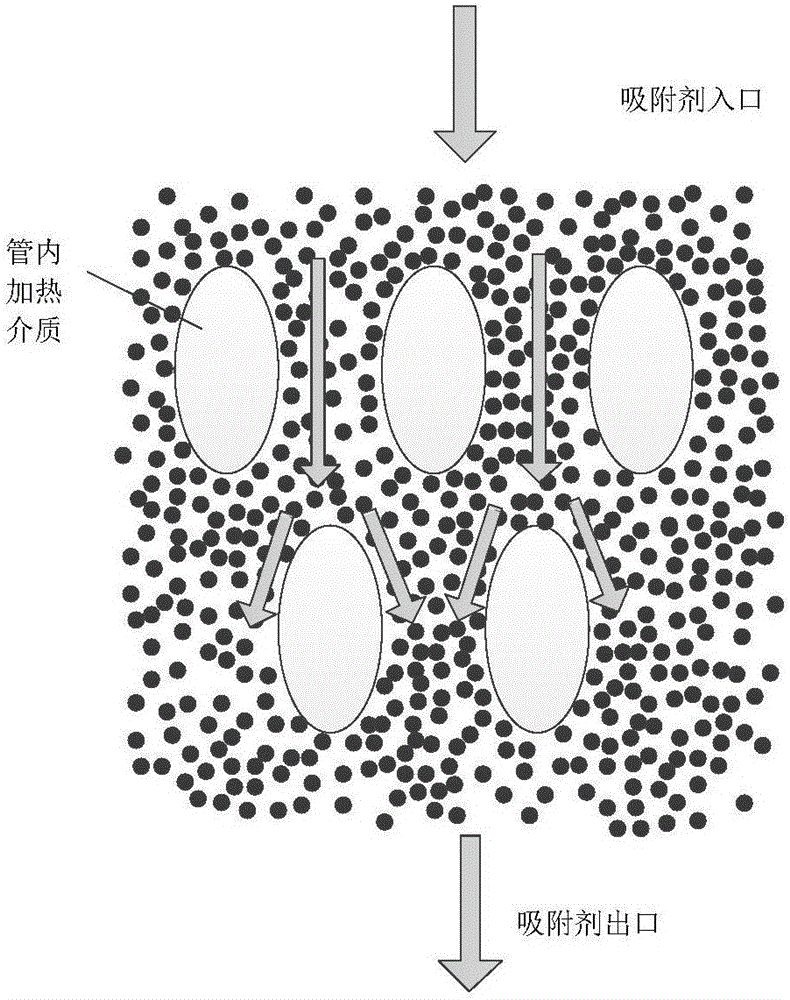

An adsorption device and organic waste gas technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of uneven temperature distribution of the desorption device, high local temperature of the desorption device, inconvenient structure and use, etc. Good heat and mass transfer effect, wide concentration range, and the effect of promoting full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

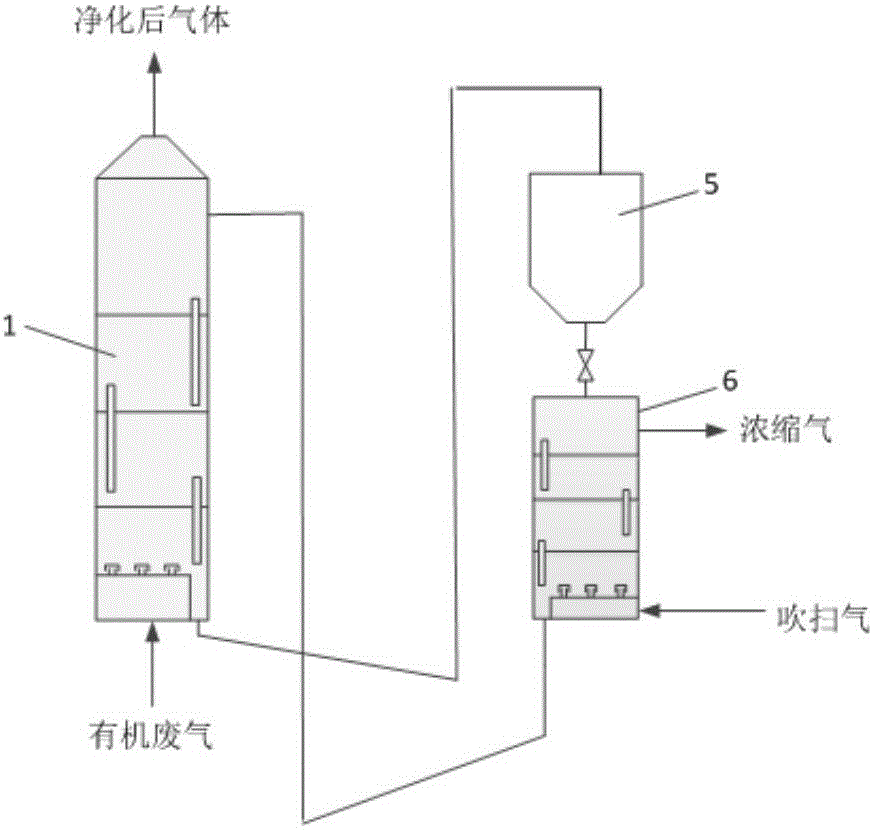

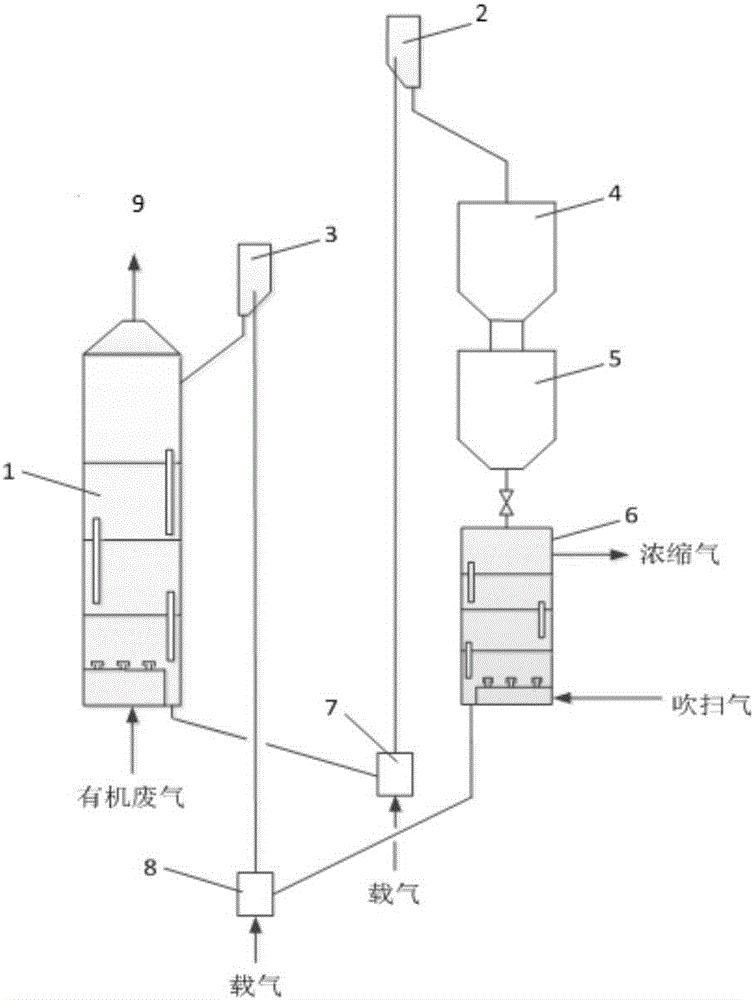

[0043] Embodiment 1 utilizes the spherical polymer resin adsorbent provided by a certain company, and the treatment concentration is 214mg / m 3 Ethyl acetate exhaust gas

[0044] The exhaust gas is introduced from the bottom of the fluidized bed adsorption device, and the gas volume is 30m 3 / h, the internal components of the fluidized bed are three-layer trays; the air is introduced from the bottom of the pneumatic conveyor, carrying the adsorbent with ethyl acetate into the separator, and then continues to be sent into the silo by the separator, and the temperature is 150 ℃ preheater for preheating, and then enter the fluidized bed desorption device with a temperature of 150 ℃ for desorption. The internal components of the fluidized bed are five-layer trays, and 8m 3 / h purge gas, take out the removed ethyl acetate, and the collected concentration is 2400mg / m 3 The condensed gas, the degassed adsorbent is discharged from the bottom and carried by the air through the pneumat...

Embodiment 2

[0045] Embodiment 2 Utilizes the spherical polymer resin adsorbent provided by a certain company, and the treatment concentration is 1094mg / m 3 Exhaust gas of o-xylene

[0046] The exhaust gas is introduced from the bottom of the fluidized bed adsorption device, and the gas volume is 30m 3 / h, the internal components of the fluidized bed are three-layer trays; the nitrogen gas is introduced from the bottom of the pneumatic conveyor, carrying the adsorbent attached to o-xylene into the separator, and then continues to be sent into the silo by the separator, and the temperature is 170 ℃ preheater for preheating, and then enter the fluidized bed desorption device with a temperature of 170 ℃ for desorption. The internal components of the fluidized bed are five-layer trays, and 8m 3 / h purge gas, take out the removed o-xylene, and collect the concentration of 2500mg / m 3 The condensed gas, the degassed adsorbent is discharged from the bottom and carried by nitrogen into the separa...

Embodiment 3

[0047] Embodiment 3 Utilizes the spherical polymer resin adsorbent provided by a certain company to deal with the air volume and low concentration produced by the furniture spray painting industry, and contains acetone, ethyl acetate and xylene with a total concentration of 320mg / m 3 exhaust gas

[0048] The exhaust gas is introduced from the bottom of the fluidized bed adsorption device, and the gas volume is 20000m 3 / h, the internal components of the fluidized bed are three-layer trays, and the feeding rate of the adsorbent is controlled at the same time to 240kg / h; the air is introduced from the bottom of the pneumatic conveyor, and the adsorbent carrying the mixed gas enters the separator, and then continues to be separated by the separator It is sent into the silo, and enters the preheater with a temperature of 170°C for preheating, and then enters the fluidized bed desorption device with a temperature of 170°C for desorption. The internal components of the fluidized bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com