Band-bubble type heat-exchanger

A heat exchanger and thermal fluid technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of uneven deformation of plates, low working temperature and working pressure, and low yield, etc. To achieve the effect of increasing the heat exchange area, improving the heat exchange efficiency, and improving the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

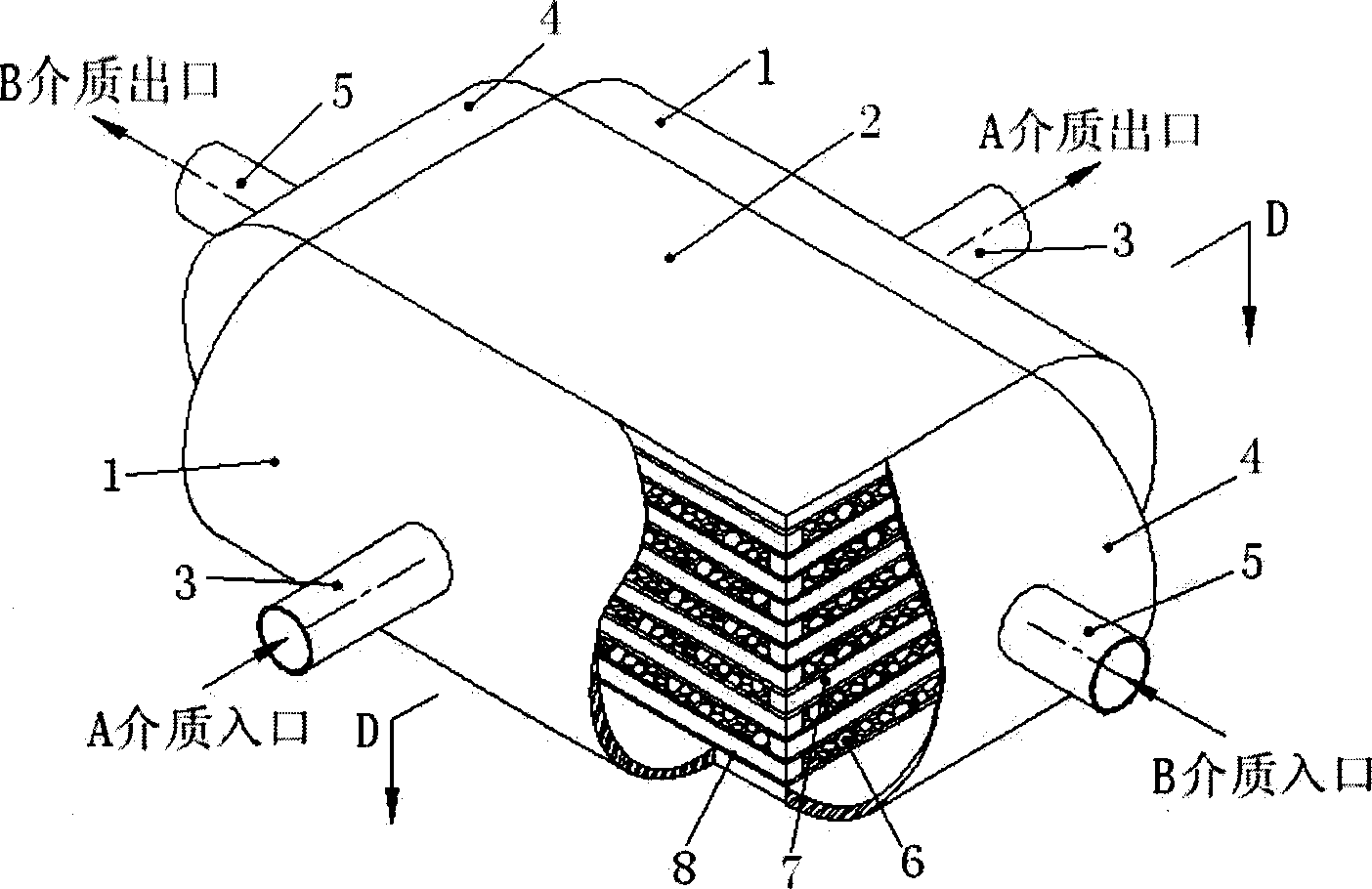

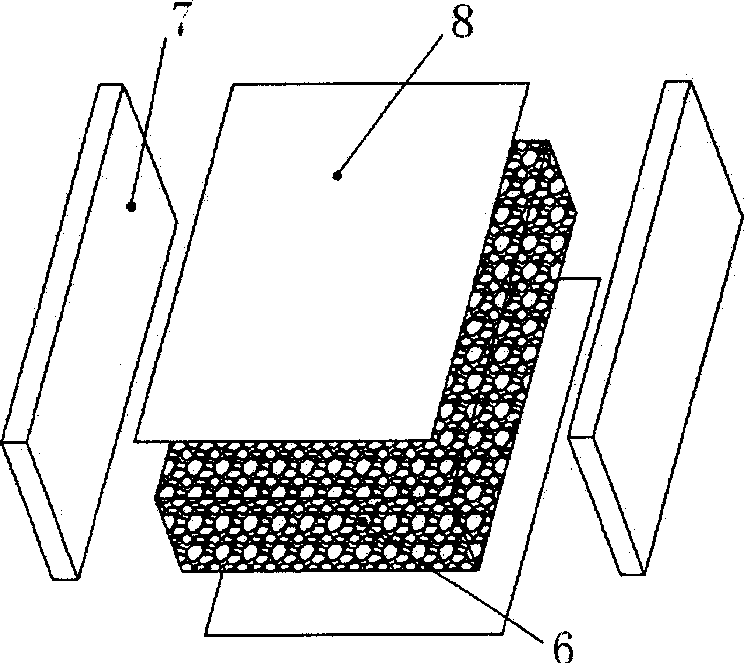

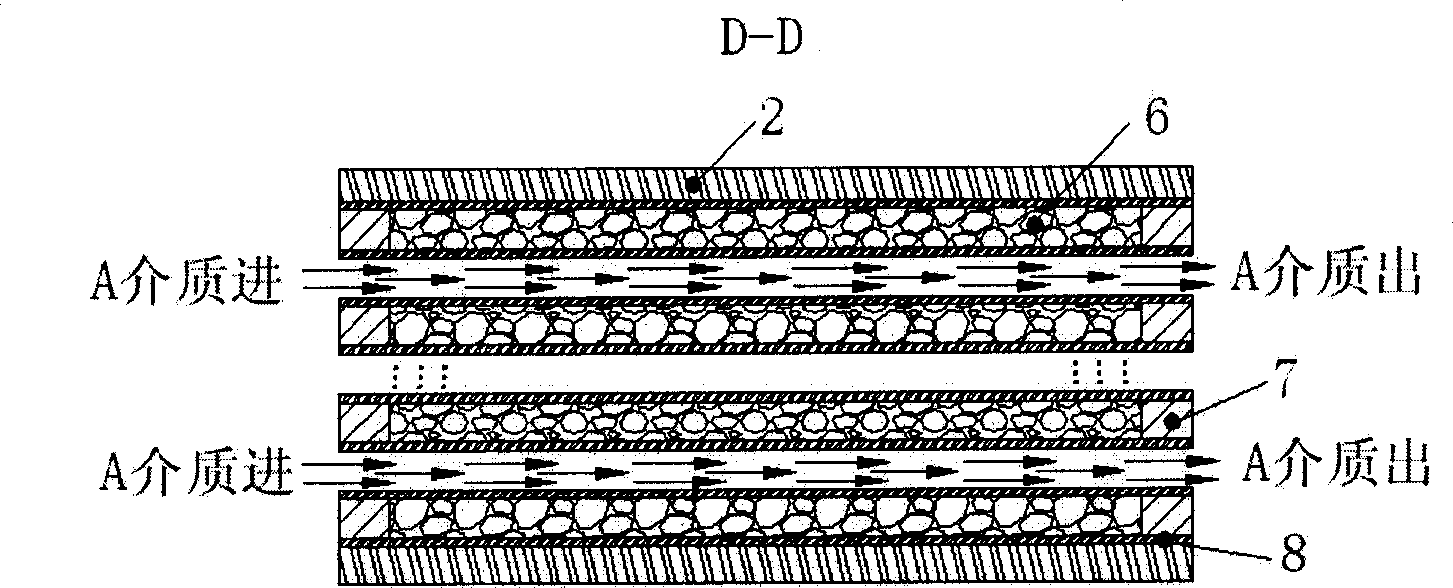

[0044] The plate-bubble heat exchanger is used as a small cooler (mainly used for cooling and heat dissipation in some working conditions), and the overall aluminum alloy material is used, and the high-conductivity foam material based on aluminum alloy (open cell structure, the opening ratio is 90 %) is used as the fluid channel of the cooler, and its core size is 20cm (width) × 20cm (length) × 13.7cm (height), adopting a cross-flow flow form, in which there are 10 channels for cold medium and 5 channels for heat medium , the average pore diameter of the porous material in the channel section is 1.5mm, the overall pressure drop is 0.5kPa, the core body weight is 1.5kg, which is less than 1 / 10 of the structure type of the plate-fin heat exchanger, and the actual heat exchanger area is 881m 2 , is more than 200 times the structural form of the plate-fin heat exchanger. The size of the average pore diameter has a great influence on the performance of the heat exchanger. With the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com