Gas extraction secondary high-pressure slip-casting hole-sealing apparatus and its hole-sealing method

A technology of gas drainage and hole sealing device, which is applied in the direction of gas discharge, safety device, sealing/isolation, etc., and can solve problems such as not being able to achieve the best sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

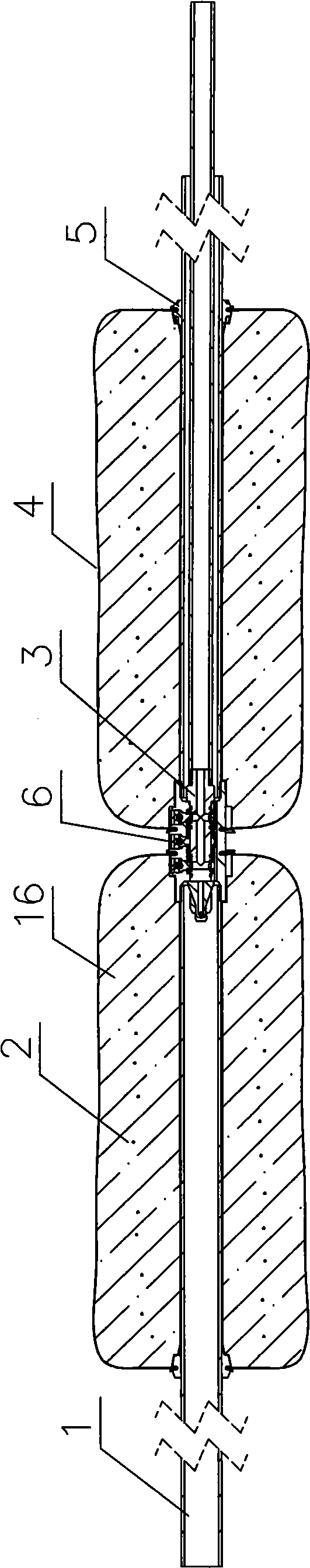

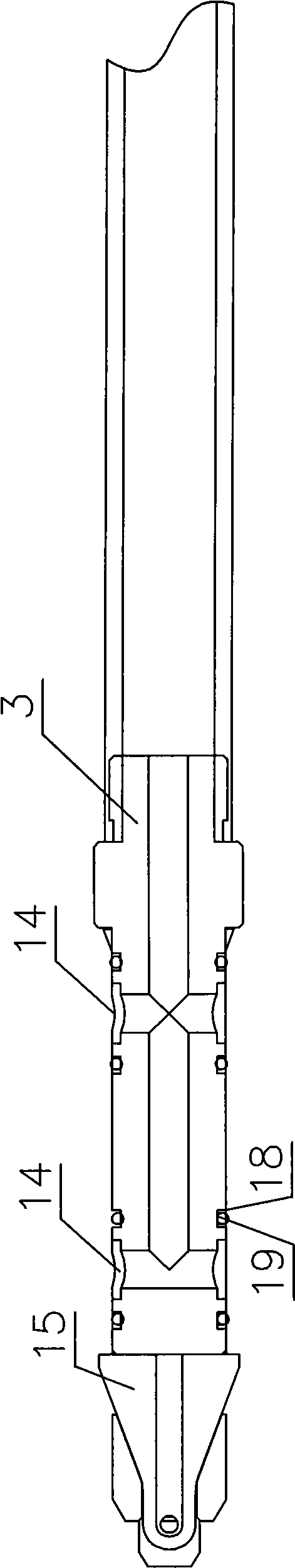

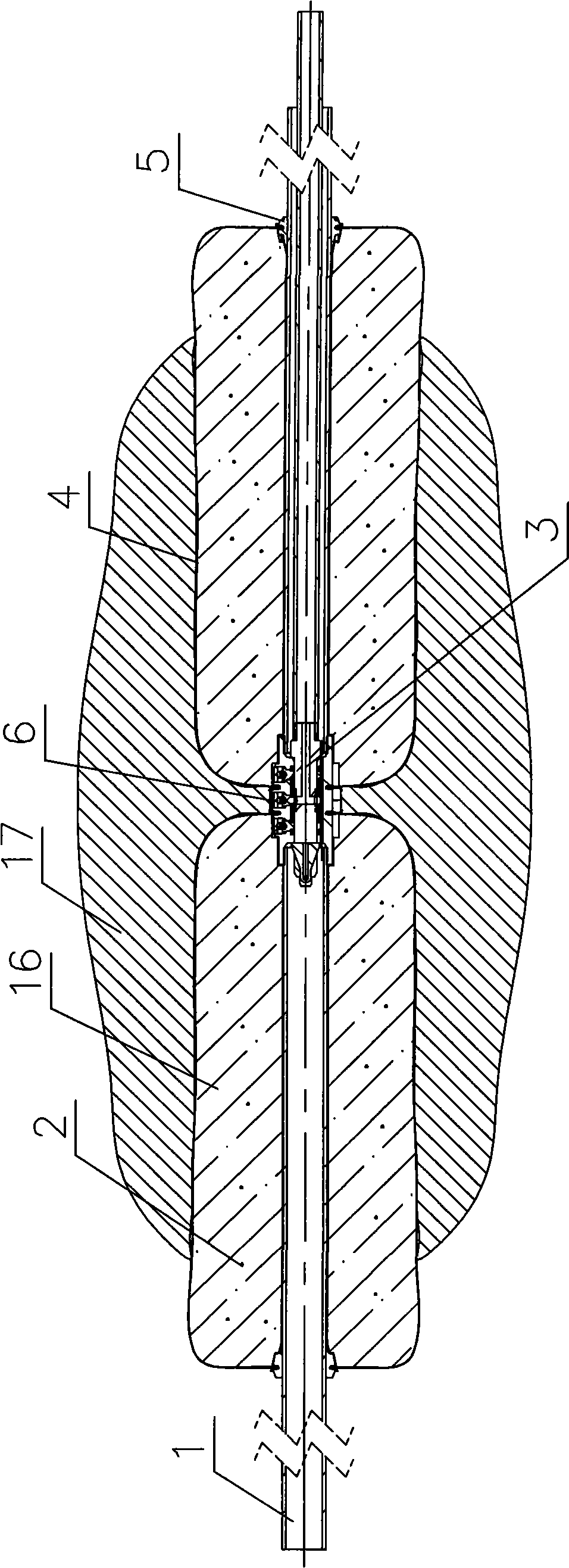

[0025] Such as figure 1 , figure 2 , Figure 7 , Figure 8 As shown, the secondary high-pressure grouting and sealing device for gas drainage includes a drainage pipe 1 and a bladder 4, and also includes a tubular secondary slurry feeding device 6, and the two sides of the secondary slurry feeding device 6 are butt-connected with drainage pipes 1. The pipe wall of the secondary pulp feeding device 6 is provided with an axial exhaust hole 13 connecting the extraction pipes 1 on both sides, and the inner pipe wall of the secondary pulp feeding device 6 is provided with a reinforced steel pipe 12. The extraction pipes 1 connected on both sides of the device 6 are provided with plugs 5 respectively, and a bag 4 is arranged between each plug 5 and the side adjacent to the secondary slurry feeding device 6, and an exhaust device is provided on the bag 4 , the exhaust device is a puncture microhole 2 arranged on the pouch 4, and the pouch 4 can be composed of a variable-diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com