High-efficiency plugging oil-base drilling fluid and preparation method thereof

A technology of oil-based drilling fluid and drilling fluid density, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as well wall collapse, improve the pressure bearing capacity of formations, be conducive to stability, and have simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

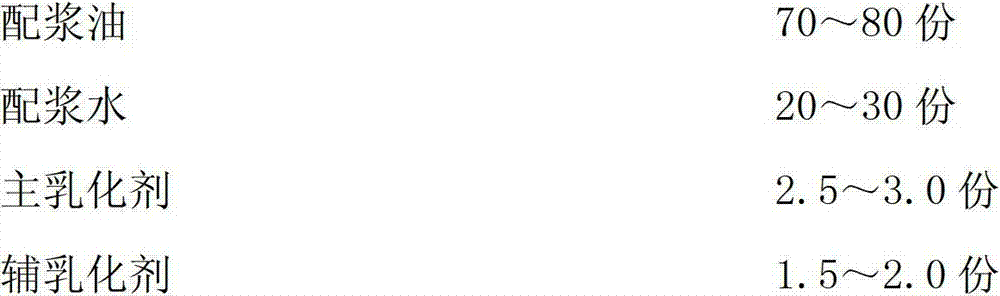

[0042] The high-efficiency plugging oil-based drilling fluid of this embodiment consists of the following raw materials:

[0043]

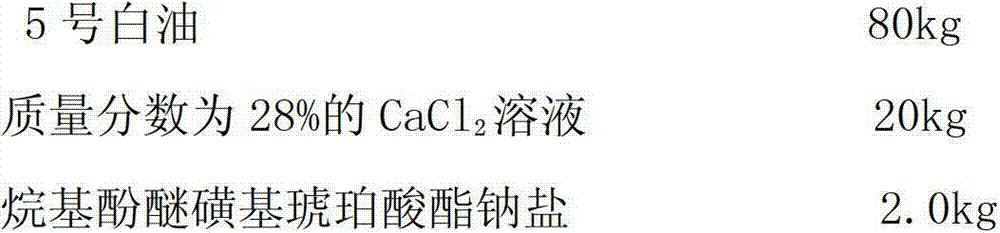

[0044]

[0045] Add barite to make the drilling fluid density reach 1.45g / cm 3 .

[0046] The preparation method of the high-efficiency plugging oil-based drilling fluid of the present embodiment comprises the following steps:

[0047] 1) Take No. 5 white oil in parts by weight, and add alkylphenol ether sulfosuccinate sodium salt, castor oil polyoxyethylene ether phosphate, fatty alcohol polyoxyethylene ether and mass fraction in sequence under stirring at 12000rpm 28% CaCl 2 Solution, measure the demulsification voltage of the water-in-oil emulsion, check the emulsion stability, and meet ES>400V;

[0048] 2) Add lecithin, imidazoline, organic soil, oxidized asphalt, humic acid, calcium oxide, xanthan gum in sequence, stir and mix well, then add sulfonated phenolic resin, water-dispersed emulsified asphalt SFT-120 (commercially available) ...

Embodiment 2

[0051] The high-efficiency plugging oil-based drilling fluid of this embodiment consists of the following raw materials:

[0052]

[0053]

[0054] Add barium carbonate to make the drilling fluid density reach 1.50g / cm 3 .

[0055] The preparation method of the high-efficiency plugging oil-based drilling fluid of the present embodiment comprises the following steps:

[0056] 1) Take No. 3 white oil in parts by weight, and add castor oil polyoxyethylene ether phosphate, polyoxyethylene sorbitan fatty acid ester and CaCl with a mass fraction of 28% in sequence under stirring at 12000 rpm 2 Solution, measure the demulsification voltage of the water-in-oil emulsion, check the emulsion stability, and meet ES>400V;

[0057] 2) Add imidazoline, oxidized asphalt, modified asphalt, humic acid, calcium hydroxide, calcium oxide, xanthan gum, and phenolic resin in sequence, stir and mix well, then add lignite resin, sulfonated phenolic resin, and water-dispersed emulsified asphalt...

Embodiment 3

[0060] The high-efficiency plugging oil-based drilling fluid of this embodiment consists of the following raw materials:

[0061]

[0062]

[0063] Add barite and limestone to make the drilling fluid density reach 1.56g / cm 3 .

[0064] The preparation method of the high-efficiency plugging oil-based drilling fluid of the present embodiment comprises the following steps:

[0065] 1) Take No. 3 white oil and No. 5 white oil in parts by weight, and add alkylphenol ether sulfosuccinate sodium salt, fatty alcohol polyoxyethylene ether, and polyoxyethylene sorrel under stirring at 12000 rpm. Alcohol fatty acid ester and mass fraction are 28% CaCl 2 Solution, NaCl solution, measure the demulsification voltage of the water-in-oil emulsion, check the emulsion stability, and meet ES>400V;

[0066] 2) Add lecithin, organic soil, oxidized asphalt, calcium hydroxide, phenolic resin in turn, stir and mix well, then add lignite resin, water-dispersed emulsified asphalt SFT120 (comme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com