Telescopic connector for logging-while-drilling instrument

An instrument while drilling, telescopic technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve problems such as wear, cable erosion, poor insulation, etc., to ensure reliability, pressure bearing capacity and reliability of parts , Avoid the effect of cable contact with mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with figure, the present invention is described in further detail:

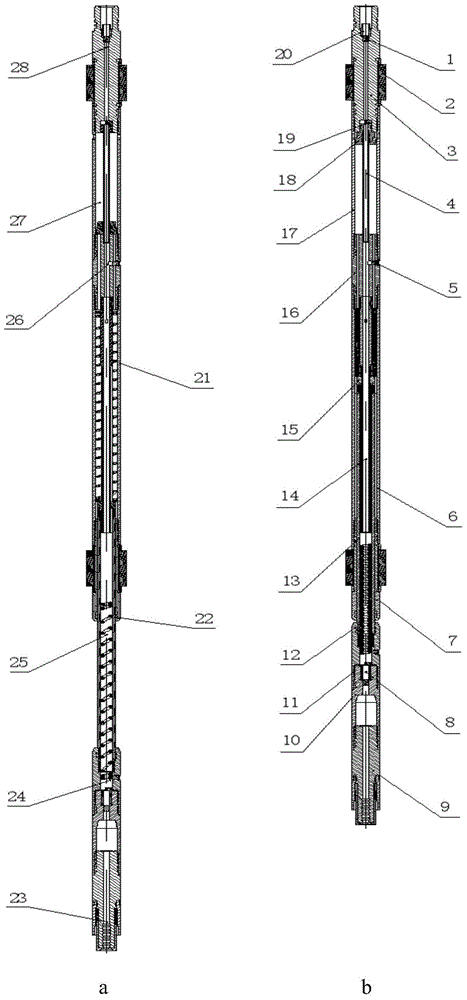

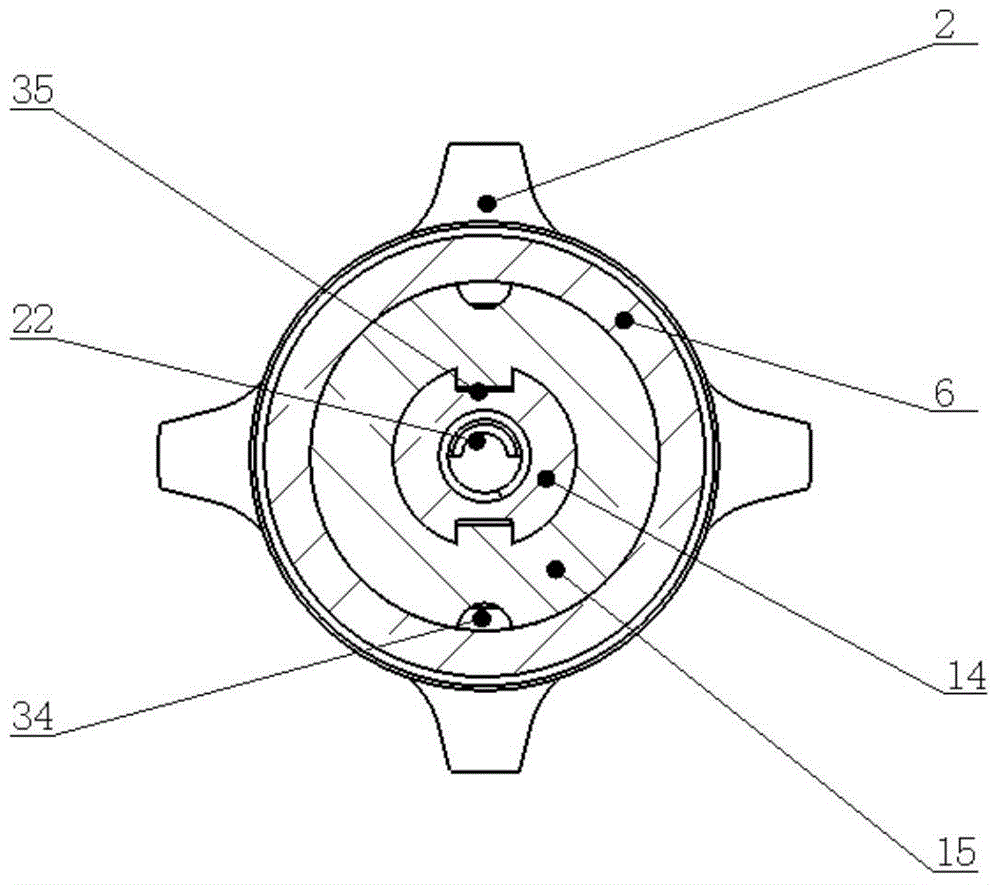

[0030] see Figure 1 to Figure 4 , The present invention is mainly composed of middle joint sub-joint 28, pressure balance sub-joint 27, upper oil injection sub-joint 26, lower oil injection sub-joint 24, telescopic sub-joint 25 and rotary connector 23. figure 1 The ultimate tension state a and the ultimate compression state b of the connector are shown in .

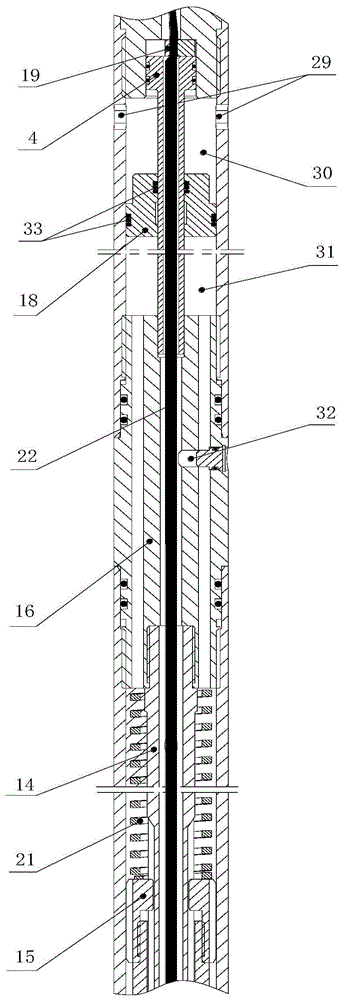

[0031] The middle joint short section 28 is connected to the upper end of the balance shell 17 by the middle joint 3 and the centralizer 2, and the other end of the middle joint 3 is connected to the MWD instrument. The high-pressure sealing plug 1 is 5 cores, installed in the sealing surface of the middle joint 3, and fixed by the sealing plug pressing ring 20. One end of the high-voltage sealing plug 1 is connected to the MWD instrument with a lead wire, and the other end is welded to the spring telescopic cable 22. One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com