Water-coal-slurry additive and preparation method thereof

An additive and coal-water slurry technology, which is applied in the field of coal-water slurry additive and its preparation, can solve the problems of high price and achieve the effects of excellent performance, simple production process and good static stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

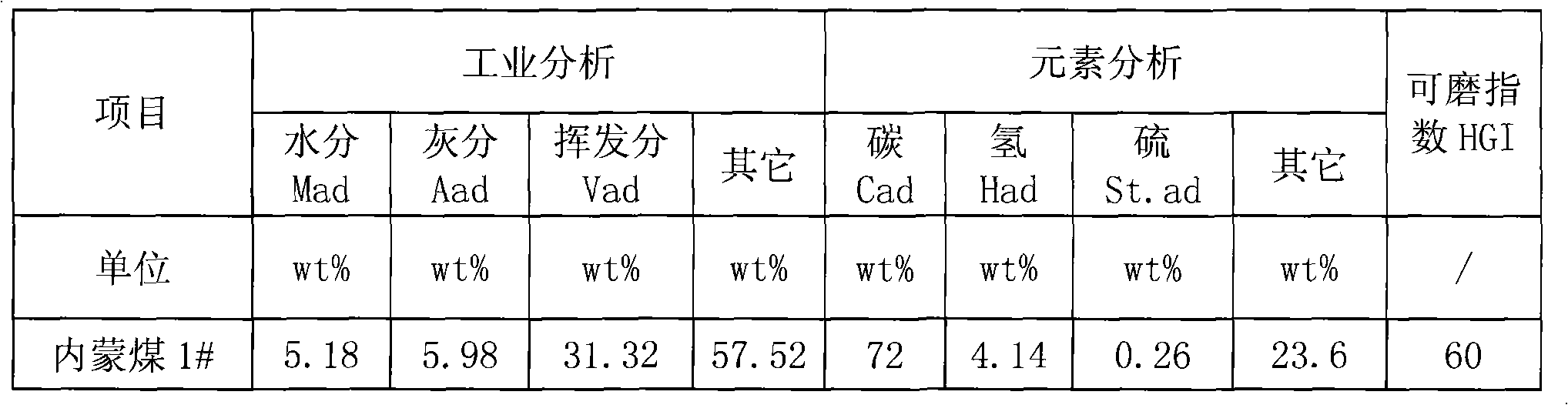

[0026] Coal sample source: Inner Mongolia Coal 1#

[0027]

[0028] Note: The industrial analysis of coal shall be determined according to GB / T212-2001; the elemental analysis of coal shall be determined according to GB / T476-2001; the grindability index of coal shall be determined according to MT / T230-2005. The following examples 2-10 are similar.

[0029] Additive type: naphthalenesulfonic acid formaldehyde condensate sodium salt: sodium lignosulfonate: octylphenol polyoxyethylene ether (meth) acrylate = 1:8:1, the degree of polymerization of naphthalenesulfonic acid formaldehyde condensate sodium salt is 7. The degree of polymerization of alkylphenol polyoxyethylene ether acrylate is 100.

[0030] Additive dosage: the quality of the composite additive (fold solid) is 0.1% of the coal (dry basis) quality.

[0031] Slurry performance results: the concentration of coal water slurry is 67%, at 25°C, the shear rate is 28.38s -1 , the apparent viscosity is 920mPa.s, and it c...

Embodiment 2

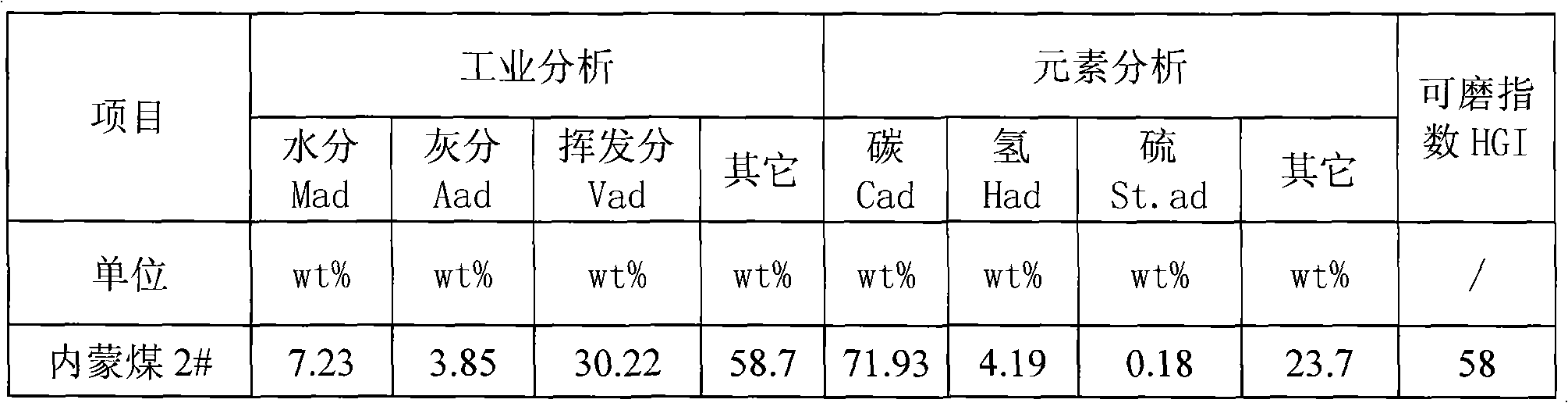

[0033] Coal sample source: Inner Mongolia Coal 2#

[0034]

[0035] Additive type: naphthalenesulfonic acid formaldehyde condensate sodium salt: calcium lignosulfonate: nonylphenol polyoxyethylene ether (meth) acrylate=5:4:1, the degree of polymerization of naphthalenesulfonic acid formaldehyde condensate sodium salt is 7. The degree of polymerization of alkylphenol polyoxyethylene ether acrylate is 10.

[0036] Additive dosage: the quality of the composite additive (fold solid) is 0.1% of the coal (dry basis) quality.

[0037] Slurry performance results: the concentration of coal water slurry is 68%, at 25°C, the shear rate is 28.38s -1 , the apparent viscosity is 880mPa.s, and it can exist stably for 10 days.

Embodiment 3

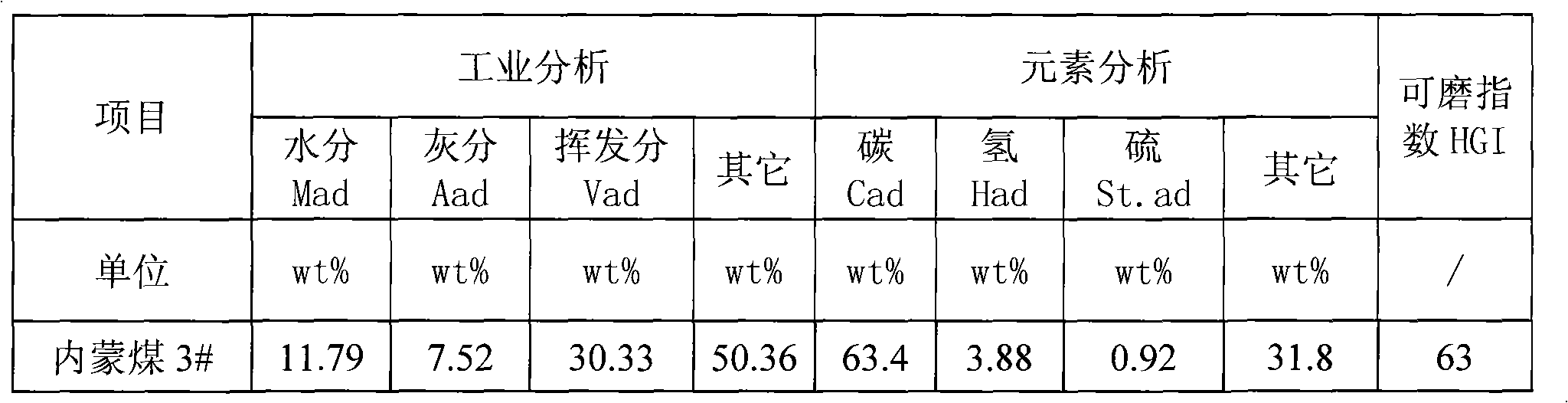

[0039] Coal sample source: Inner Mongolia Coal 3#

[0040]

[0041] Additive type: naphthalenesulfonic acid formaldehyde condensate sodium salt: sodium lignosulfonate: [dodecylphenol polyoxyethylene ether (meth)acrylate and nonylphenol polyoxyethylene ether (meth)acrylate] = 8:1:1, the degree of polymerization of naphthalenesulfonic acid formaldehyde condensate sodium salt is 15, and the polymerization degree of alkylphenol polyoxyethylene ether acrylate is 40.

[0042] Additive dosage: the quality of the composite additive (fold solid) is 1% of the coal (dry basis) quality.

[0043] Slurry performance results: the concentration of coal water slurry is 63%, at 25°C, the shear rate is 28.38s -1 , the apparent viscosity is 1040mPa.s, and it can exist stably for 5 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com