Two-package curing type polyurethane paint and preparation thereof

A polyurethane coating and hardening technology, applied in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problems of low TDI boiling point, unsuitable coatings, high viscosity of polyurethane coatings, etc., and achieve excellent tensile strength, Strong operability and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

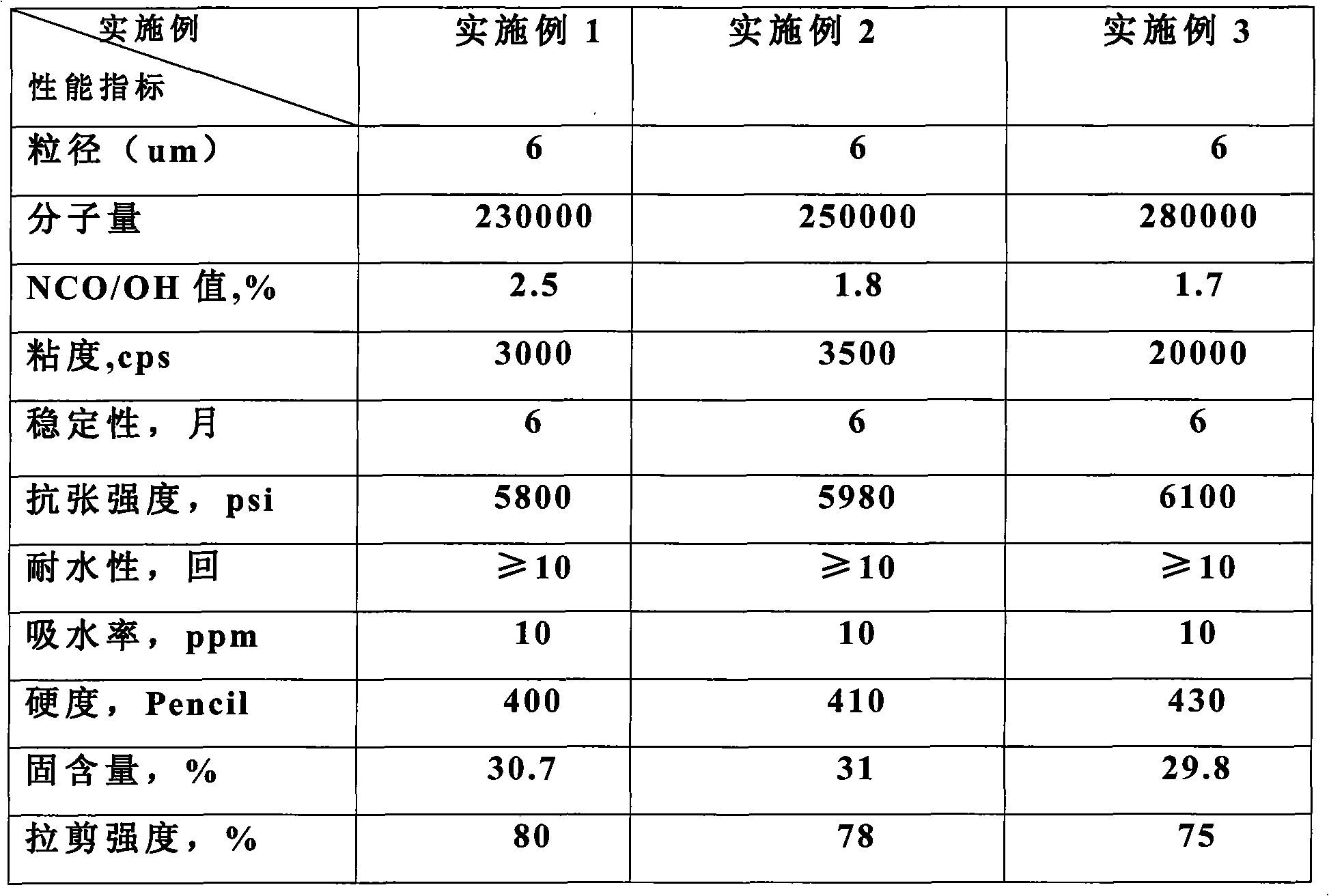

Embodiment 1

[0019] According to the raw material formula of the two-liquid hardening type polyurethane coating of the present embodiment is:

[0020] 70 grams of polydihydrofuran ether diol (molecular weight 735), 60 grams of 1,4-butanediol, 158 grams of MDI, and 650 grams of dimethylformamide (DMF).

[0021] Polyurethane coatings are prepared as follows:

[0022] Add 70 grams of polydihydrofuran ether diol, 60 grams of 1,4-butanediol and 650 grams of DMF into a 2000 mL four-neck reactor, stir rapidly, heat to about 70 ° C, carry out under dry nitrogen, and gradually add MDI After reacting for about 1 hour, when it reaches the theoretical value of 158 grams, take a little reactant for FTIR spectral characteristic absorption peak test until the peak near 2270CM-1 disappears, which means the reaction is complete.

Embodiment 2

[0024] According to the raw material formula of the two-liquid hardening type polyurethane coating of the present embodiment is:

[0025] 70 grams of polydihydrofuran ether diol (molecular weight 700), 60 grams of 1,4-butanediol, 185 grams of MDI, and 700 grams of dimethylformamide (DMF).

[0026] Polyurethane coatings are prepared as follows:

[0027] Add 70 grams of polydihydrofuran ether diol, 60 grams of 1,4-butanediol and 650 grams of DMF into a 2000 mL four-neck reactor, stir rapidly, heat to about 70 ° C, carry out under dry nitrogen, and gradually add MDI , reacted for 1 hour, measured the viscosity of the system as 3500 (25°C), stopped adding MDI, and obtained the coating of this embodiment.

Embodiment 3

[0029] According to the raw material formula of the two-liquid hardening type polyurethane coating of the present embodiment is:

[0030] 70 grams of polydihydrofuran ether glycol (molecular weight 750), 60 grams of 1,4-butanediol, 185 grams of MDI, and 750 grams of DMF.

[0031] Polyurethane coatings are prepared as follows:

[0032] Add 70 grams of polydihydrofuran ether diol, 60 grams of 1,4-butanediol and 650 grams of DMF into a 2000 mL four-neck reactor, stir rapidly, heat to about 70 ° C, carry out under dry nitrogen, and gradually add MDI , reacted for 1 hour, measured the viscosity of the system as 20000 (25°C), stopped adding MDI, and obtained the coating of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com