Composites and methods for treating bone

a technology of composite materials and bone, applied in the field of composite materials, can solve the problems of fractures in the spine and hips, affecting mobility and quality of life, and the medical advances aimed at slowing or arresting bone loss from aging have not provided solutions to this problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

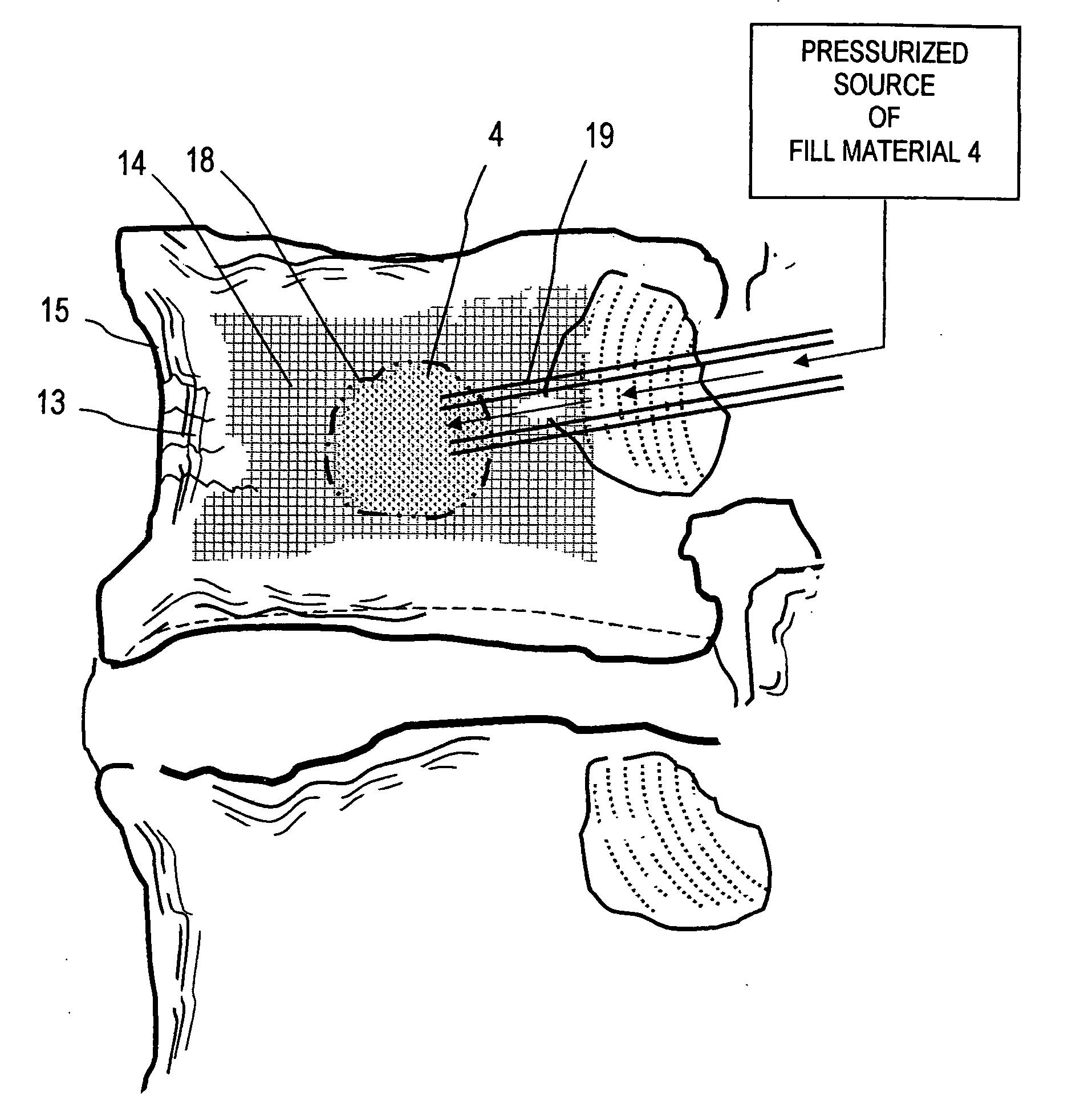

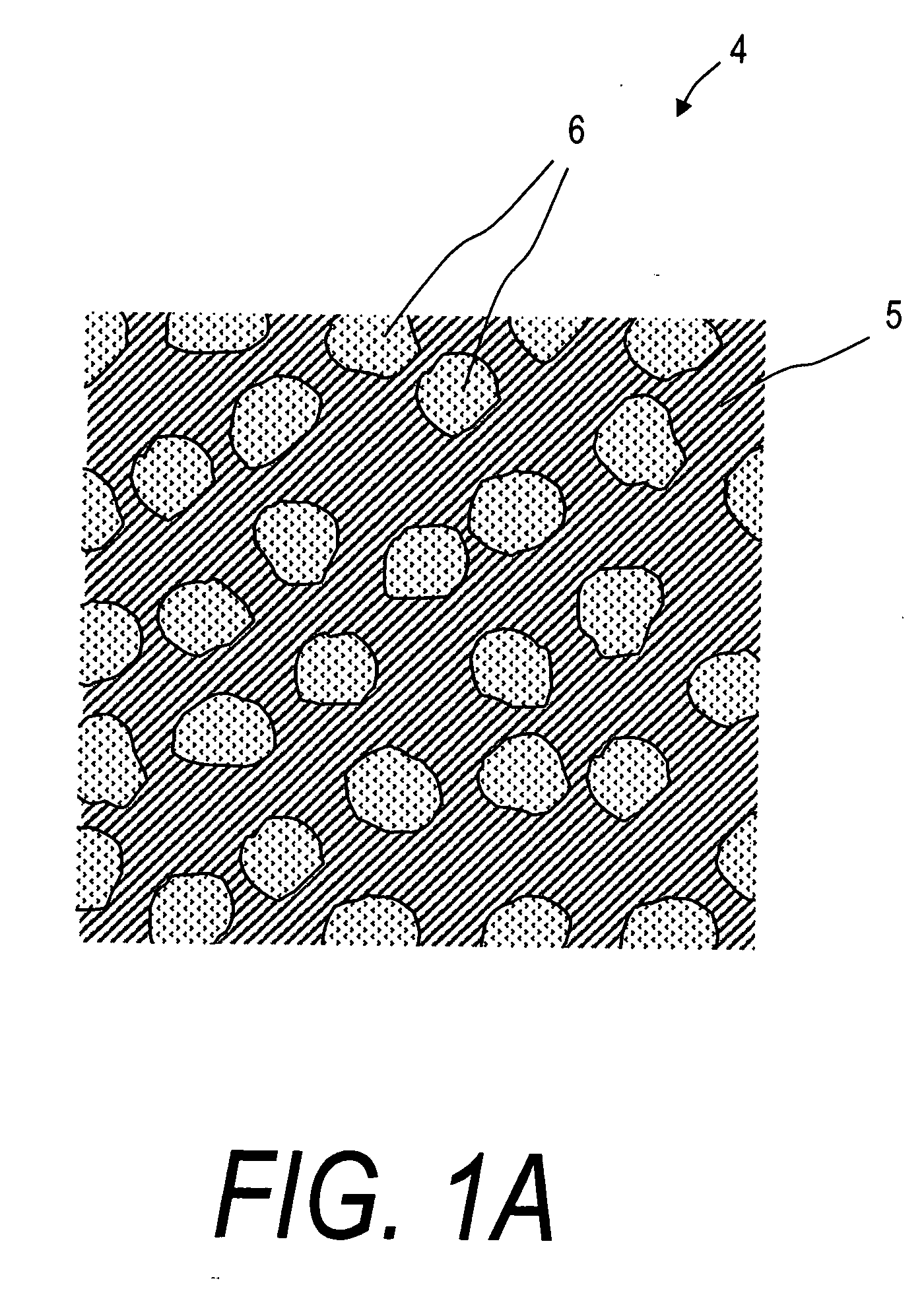

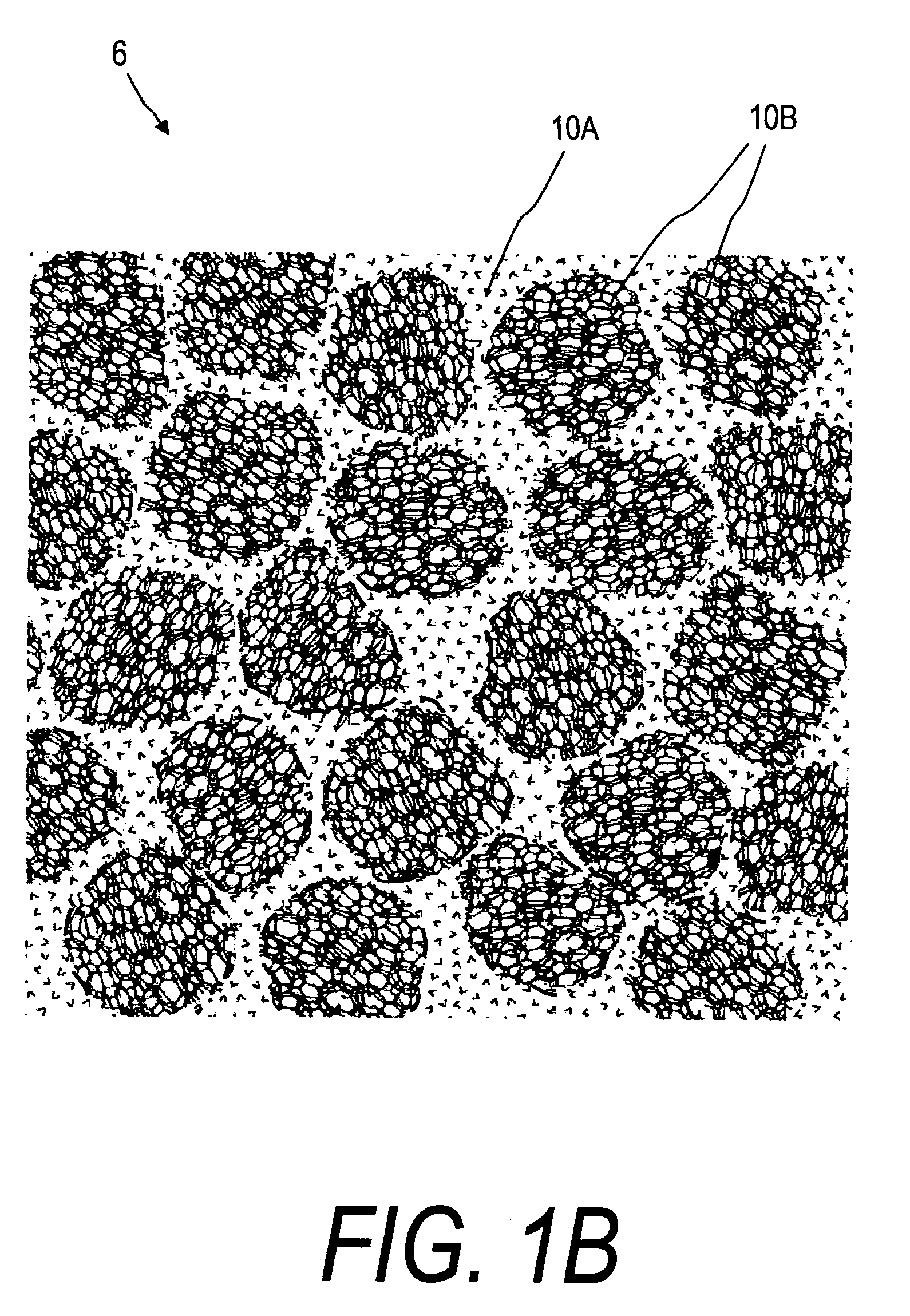

[0029]FIG. 1A illustrates a cross-sectional view of fill material 4 that comprises flowable component 5 with elastomeric polymer component 6 dispersed therein. The flowable component or material 5 is an in-situ hardenable bone cement (e.g., PMMA) that is intermixed with elastomeric component 6 that comprises a plurality of small elastomeric elements, such as silicone particles or elements of another biocompatible polymer. The flowable material 5 and elastomeric elements 6 can be intermixed prior to introduction into bone or contemporaneous with introduction into bone from separate channels in an introducer. The elastomeric elements 6 are typically dimensioned to be small enough to allow their passage within the openings of cancellous bone in a targeted treatment site. In one embodiment as depicted in FIG. 1B, the elastomeric elements 6 themselves comprise a composite of base elastomer 10A and reticulated, open-cell scaffold structures indicated at 10B. Such reticulated open-cell str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com