Anchoring force pre-warning device for anchor rod

A technology of early warning device and anchoring force, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of many device components and cumbersome operation process, so as to improve the integrity, ensure safe and efficient production, The effect of improving the support ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

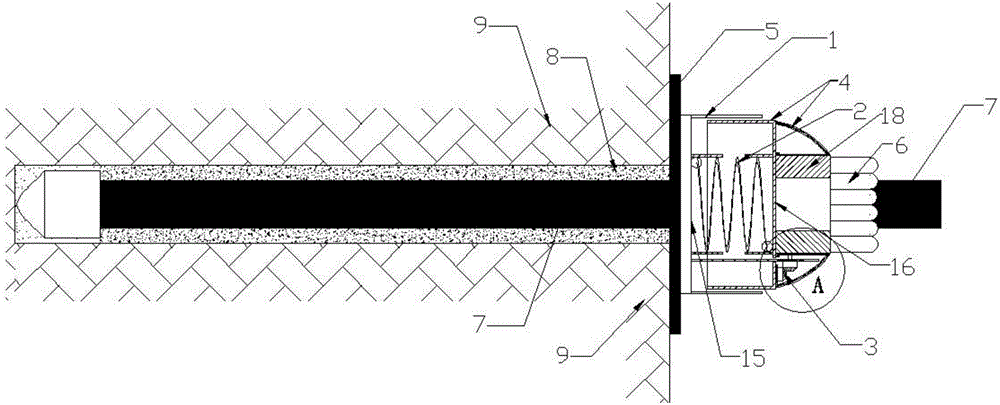

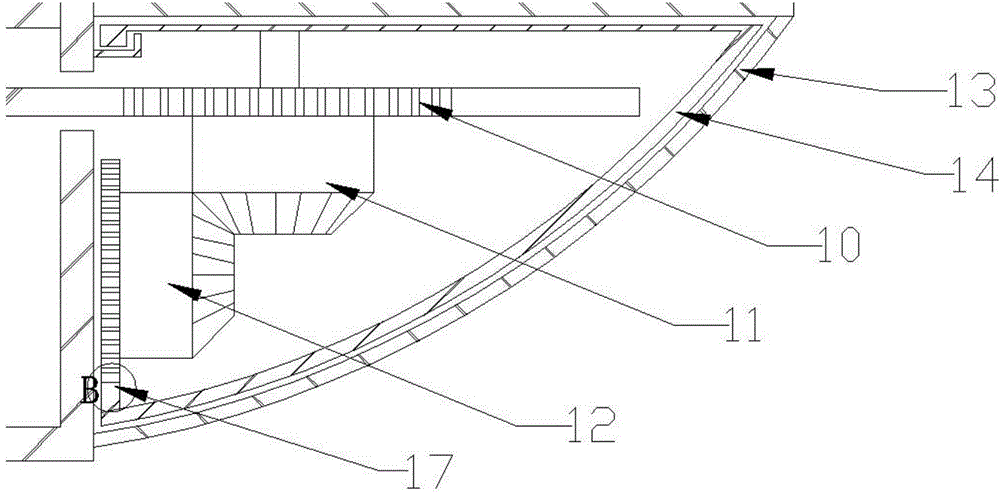

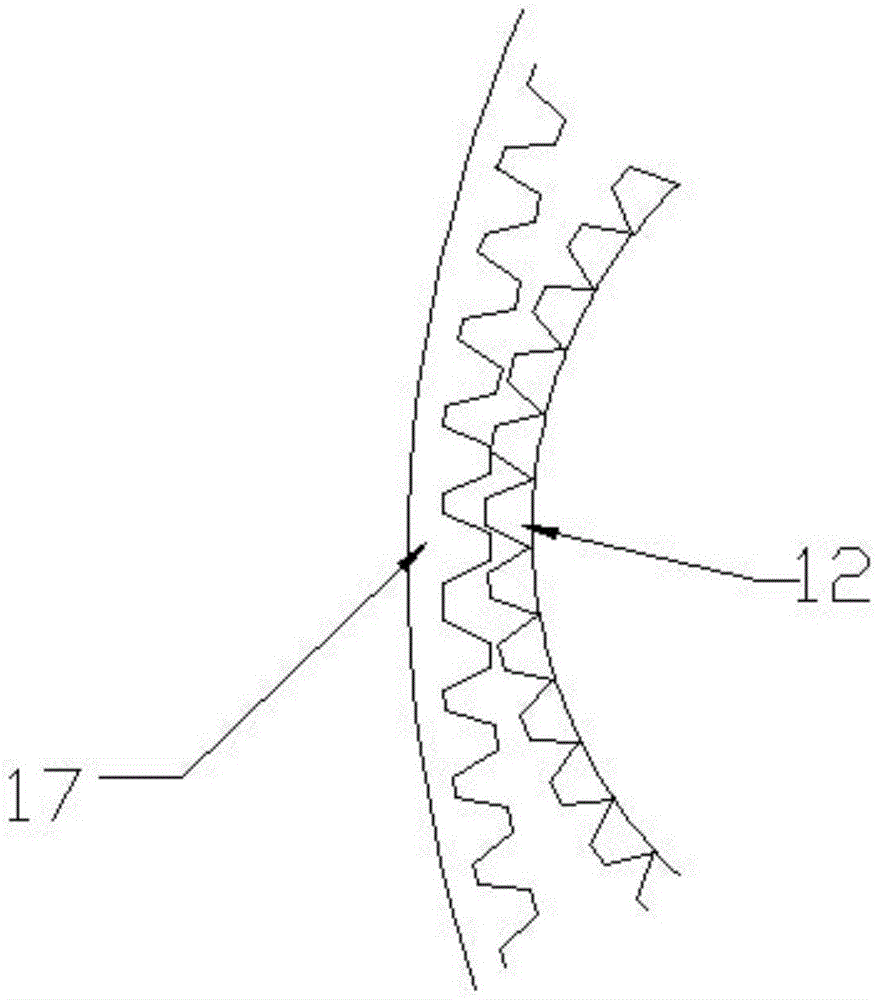

[0023] like Figure 1-7 As shown, the bolt anchoring force early warning device of the present invention includes: a shell 1, a high-strength central spring 2, a rack 10, a side reflective tape and a rotatable wide-angle reflective tape 4, a vertical plastic helical bevel gear 3, and an outer ball Shell 13 and inner spherical shell 14, upper base 15 and lower base 16, hollow cylinder 18, the central spring 2 is welded in the central circular groove of the upper base 15 and the lower base 16; the bottom end of the rack 10 Welded on the upper base 15, the rack 10 extends into the inner spherical shell 14 through the small hole on the edge of the central circular groove of the lower base 15, and the rack 10 is meshed with the vertical gear 11; the vertical gear 11 is connected with the horizontal gear 12 toothed and connected; the large-diameter inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com