Experimental device for hydraulically simulating non-uniform confining pressure of casing pipe and using method

An experimental device and non-uniform technology, applied in the field of simulation experiments, to achieve the effect of preventing casing instability and damage, preventing instability and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

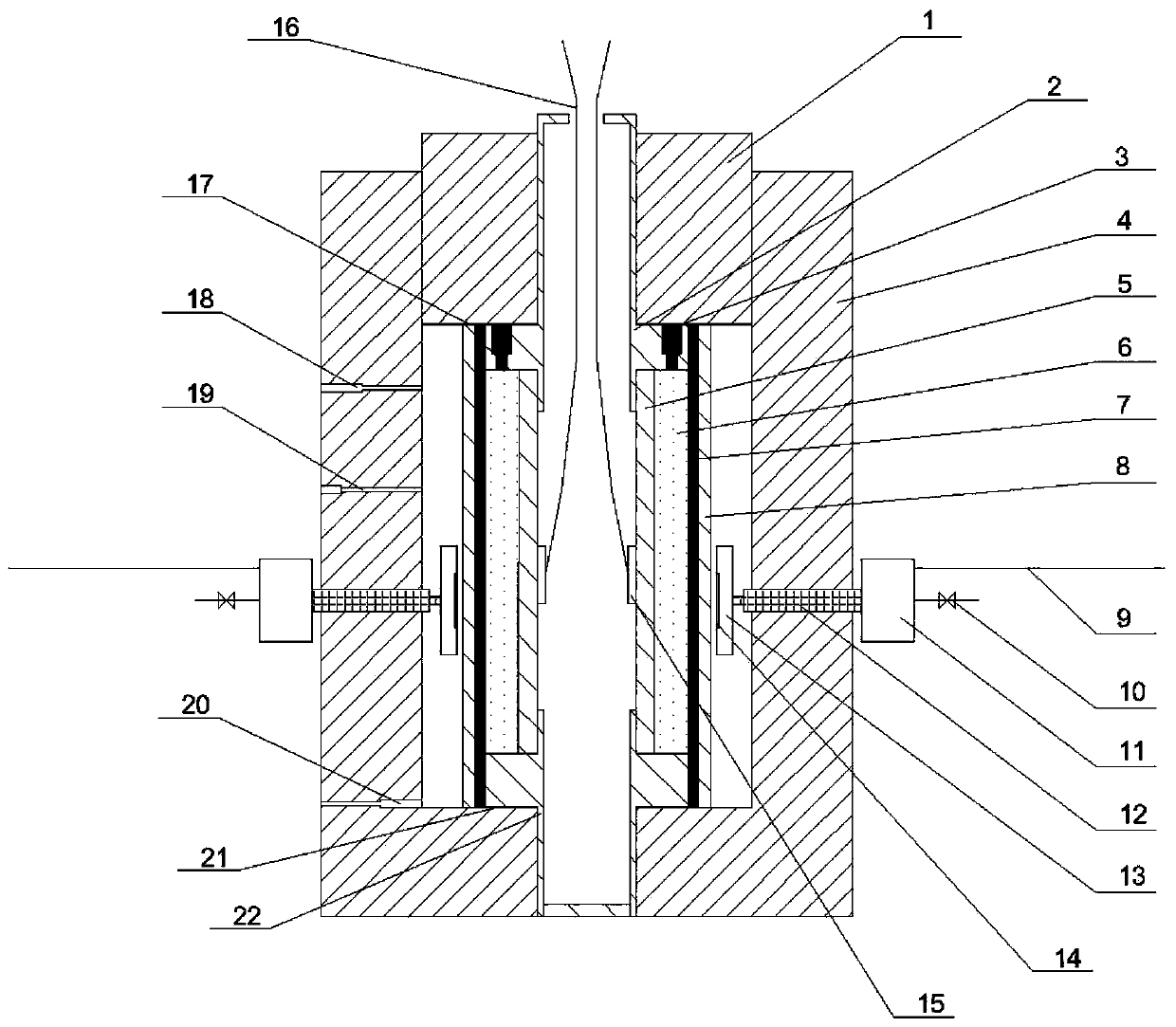

[0042] Embodiment 1. Embodiment 1 is an experimental device for hydraulically simulating non-uniform confining pressure of casings with 4 groups of pressurized components

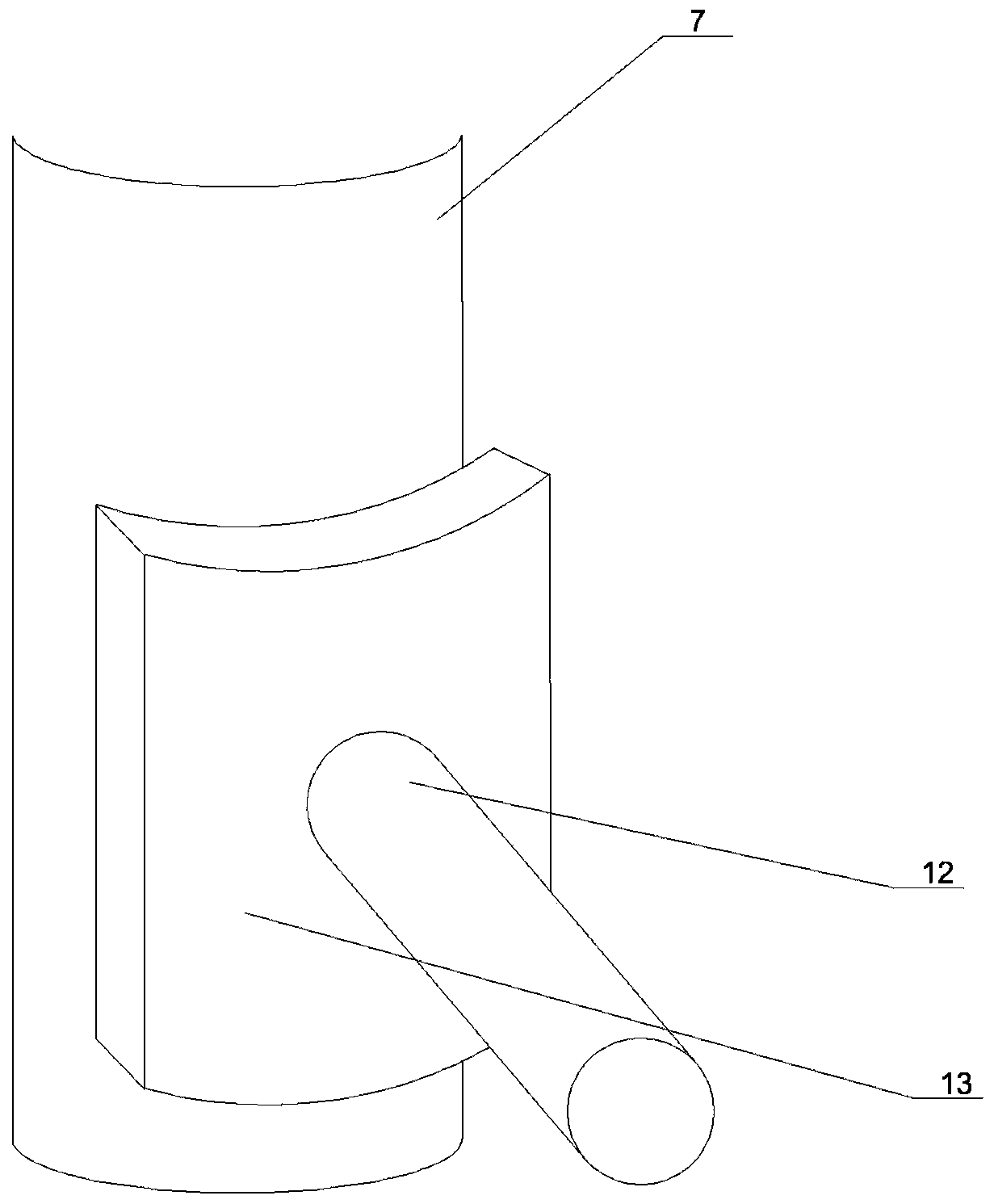

[0043] Such as figure 1 , figure 2 , image 3 As shown, a hydraulic simulation experiment device for casing non-uniform confining pressure of the present invention comprises kettle cover 1, casing upper cover 2, cement sprue 3, kettle body 4, casing 5, cement sheath 6, rubber Cylinder 7, double semicircular cylinder liner 8, built-in data line 9, air valve 10, pneumatic hydraulic pump 11, hydraulic push rod 12, mechanical pusher 13, strain patch 14, strain gauge 15, strain gauge data line 16, top sealant Ring 17, water inlet 18, thermocouple 19, water outlet 20, bottom sealing rubber ring 21, casing lower cover 22.

[0044] The experimental device includes a kettle body assembly, an experimental assembly, a data acquisition assembly, and a pressurization assembly.

[0045] The kettle body assembly incl...

Embodiment 2

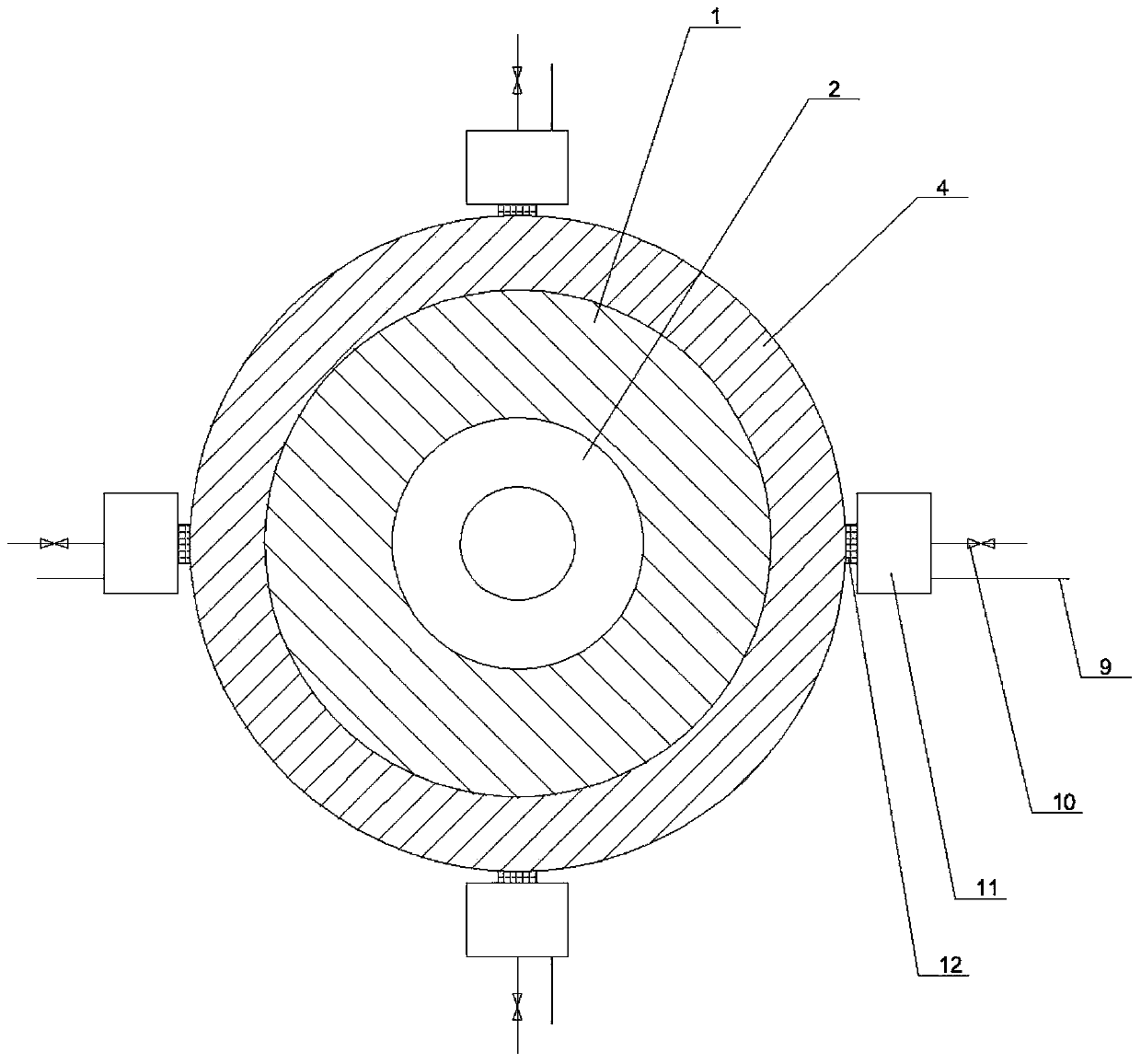

[0058] Embodiment 2. Embodiment 2 is an experimental device for hydraulic simulation of casing non-uniform confining pressure of 8 groups of pressurized components

[0059] Such as figure 1 , figure 2 , Figure 4 As shown, the structure of this embodiment 2 is basically the same as that of embodiment 1, the difference is that the number of pressurized components is 8 groups, the angle between the pressurized components and the center line of the kettle body is 45°, and the distribution density is higher. The higher the pressure, the greater the distribution of the confining pressure that the pressurizing component can achieve when applying pressure to the casing 5, and the more realistic simulation of the impact of the non-uniform confining pressure in the formation on the casing 5 and the cement sheath 6.

[0060] The test method of embodiment 2 is:

[0061] First, the strain gauge 15 is evenly attached to the corresponding position on the inner wall of the casing 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com