Visual servo-loading seepage test method for cracked coal and rock sample

A technology for crushing coal rocks and testing methods, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, permeability/surface area analysis, etc., can solve actual measurement, difficult to collapse zone pore structure and permeability, etc. problem, to achieve the effect of safe and efficient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

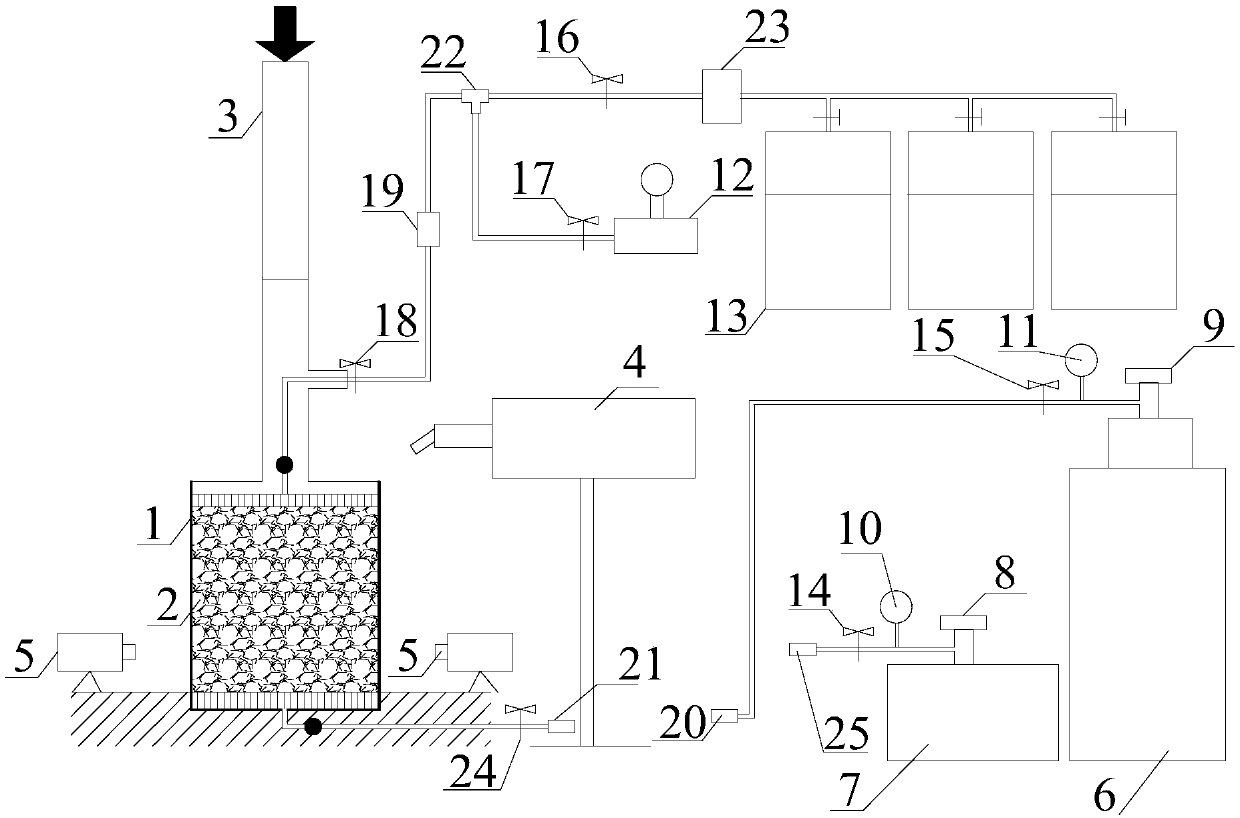

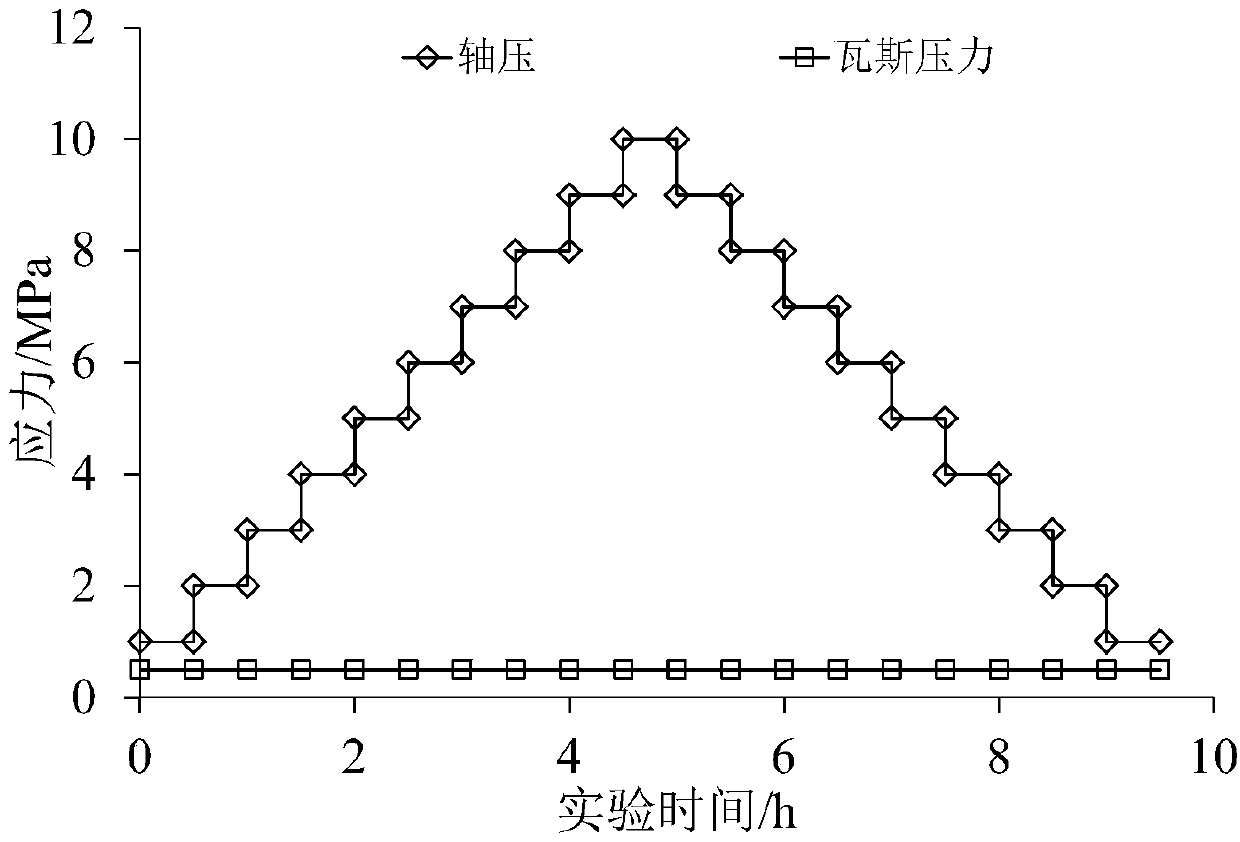

[0019] The present invention adopts a set of visual servo loading seepage test system for broken coal rock samples, the system mainly includes: visual transparent kettle body 1 (using transparent resin material), automatic servo loading device 3, micro-focus CT scanner 4, high-speed camera 5 , automatic gas source 6, hydraulic pump 7, gas cylinder pressure gauge 11, gas flow meter 13, liquid flow meter 12, automatic switching of the gas-liquid seepage test is realized through the gas-liquid automatic switching valve 22. The broken coal rock sample visual servo loading seepage test method of the present invention mainly includes compaction stress path measurement, broken coal rock sample preparation, stress test point selection, CT scanning, permeability test, high-speed camera shooting, pore structure reconstruction and various The mutual cooperation betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com