Method for replacing middle bottom-extraction rock roadway with bottom-extraction rock roadway kilometer directional long borehole

A long drilling and rock roadway technology, applied in directional drilling, earthwork drilling, gas discharge, etc., can solve the problems of poor coal seam air permeability, difficulty in forming holes, high investment cost, etc., and achieve good hole quality, drainage and slag discharge Convenience and the effect of prolonging the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be clearly described below in conjunction with the drawings and specific embodiments in the embodiments of the present invention. The description here is only used to explain the present invention, but not as a limitation to the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative work, any modifications, equivalent replacements, improvements, etc., shall be included in the protection scope of the present invention Inside.

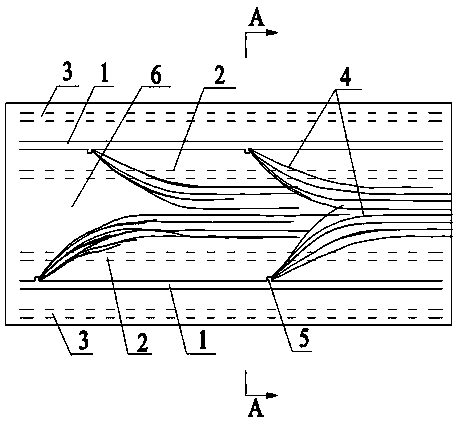

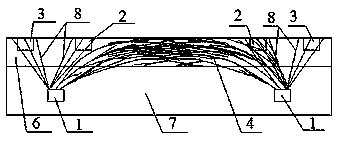

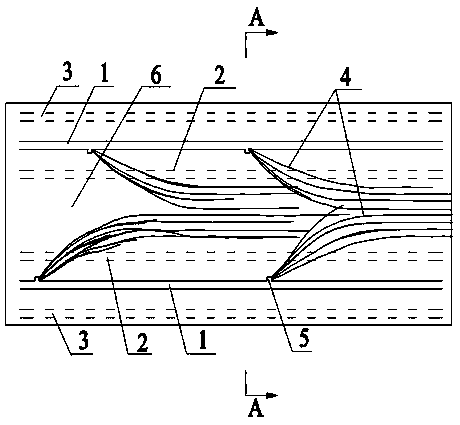

[0023] like Figure 1-2 Shown, a kind of bottom pumping rock roadway kilometer directional long drilling replaces the method of bottom pumping rock roadway in the middle, is to utilize high gas, outburst mines to generally construct and have along groove bottom pumping rock roadway 1 to cover mining working face along groove roadway 2 and The construction method of excavating along the channel roadway 3 on the standby mining face,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com