Multi-tubular large-capacity microwave extraction machine and microwave extraction method thereof

A large-capacity, extraction machine technology, applied in solid solvent extraction, chemical/physical/physical-chemical processes of applied energy, etc., can solve the problems of small sample volume, insufficient utilization, long extraction time, etc. The effect of power-on time, energy and raw material saving, and shortening of extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

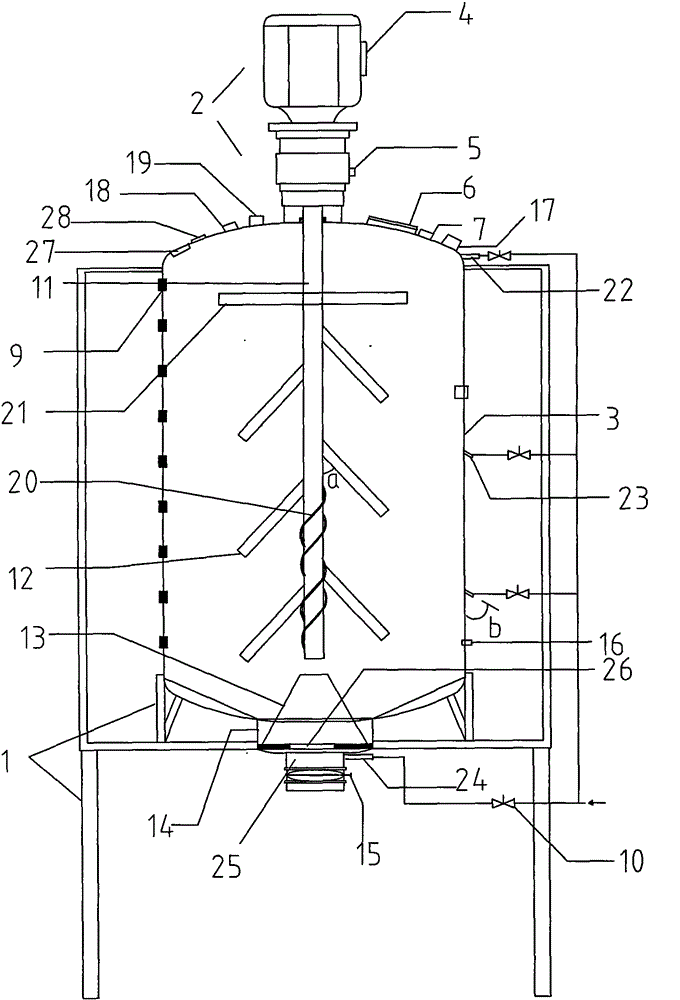

[0036] refer to figure 1, an embodiment of the present invention is proposed, including a frame 1, a transmission device 2, a microwave tank 3, a microwave device, an air filling device, a rotor device, a discharge device, and a control device, and the frame 1 supports the microwave tank 3, The transmission device 2 includes a motor 4 capable of forward and reverse rotation, a reducer 5, and the reducer outputs power to the rotor device. The top of the microwave tank is provided with a feeding port 6 and a water inlet 7, and a discharge device 8 is provided at the bottom. There are several magnetron mounting holes evenly and equidistantly distributed on the tank wall; the microwave device includes several high-frequency magnetrons 9 evenly and equidistantly arranged on the microwave tank wall, and the high-frequency m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com