Subcritical continuous walnut oil extraction method and extraction tank group

An extraction tank and subcritical technology is applied in the field of walnut oil extraction, extraction tank group, and subcritical continuous extraction of walnut oil. Avoid nutrient loss, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

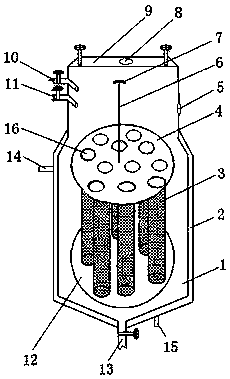

Image

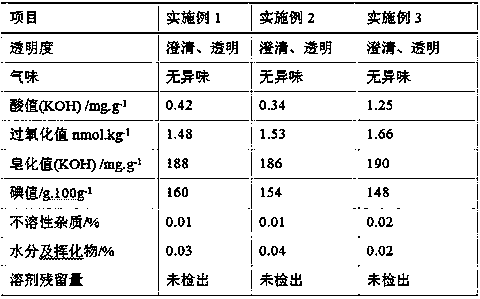

Examples

Embodiment 2

[0050] The method for utilizing the subcritical continuous extraction of walnut oil of the above-mentioned extraction tank group of the present embodiment comprises the following steps:

[0051] Step (1), pretreatment: cold press the walnut kernel raw material through a hydraulic oil press to obtain walnut cake containing 17.6% residual oil, and crush the cake to 40 mesh to obtain walnut meal powder.

[0052] Step (2), extraction:

[0053] In step (2), the countercurrent subcritical fluid continuous extraction is specifically to place the same amount of walnut meal powder in the material barrel 3 of the first, second and third extraction tanks respectively, according to the propane: cake powder volume ratio of 1.2:1. Propane was injected into the first extraction tank, mixed with the raw materials for the first extraction, the extraction time was 22min, the extraction pressure was 0.4MPa, and the extraction temperature was 45°C.

[0054] The obtained extract is poured into th...

Embodiment 3

[0066] The method for utilizing the subcritical continuous extraction of walnut oil of the above-mentioned extraction tank group of the present embodiment comprises the following steps:

[0067] Step (1), pretreatment: cold press the walnut kernel raw material through a hydraulic oil press to obtain walnut cake containing 17.6% residual oil, and crush the cake to 20 mesh to obtain walnut meal powder.

[0068] Step (2), extraction:

[0069] In step (2), the countercurrent subcritical fluid continuous extraction is specifically to place the same amount of walnut meal powder in the material barrel 3 of the first, second and third extraction tanks respectively, according to the volume ratio of liquefied petroleum gas: cake powder 1: 1. Inject liquefied petroleum gas into the first extraction tank and mix it with raw materials for the first extraction. The extraction time is 25 minutes, the extraction pressure is 0.8MPa, and the extraction temperature is 55°C. The obtained extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com