Dynamic detection method for mine mining-induced fracture

A dynamic detection and fracture technology, applied in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of increasing the rationality of hole layout, prolonging the extraction time, blind hole layout, etc., to increase the rationality of hole layout. , the effect of prolonging the extraction time and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below.

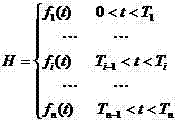

[0025] Concrete technological process of the present invention is as follows:

[0026] The first step: design the required detection drilling location, parameters and quantity.

[0027] According to the downhole conditions, choose a suitable location for construction and detection of drilling pits. Generally, it is selected near the designed recovery line, and the vertical plane where the recovery line is located is used as the detection object to ensure that there is enough time to complete the drilling construction and detection tasks, and to ensure that the detection can be completed. The drilling rig, electricity, water pressure and space required for the task; design the aperture, length, azimuth and elevation of the detection borehole according to the location of the drilling hole, the performance of the drilling rig, and the distance and azimuth of the target to be detected. They are all parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com