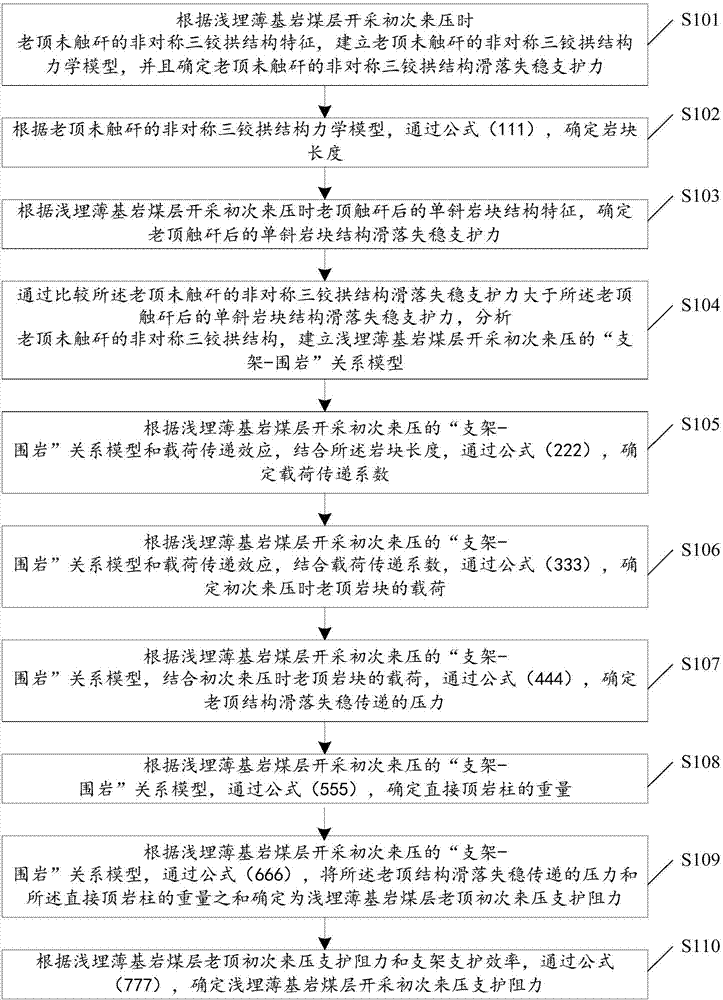

Method for determining first weighting supporting resistance of shallow thin bedrock coal seam mining

A determination method and thin bedrock technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to fully guide the mining of shallow buried thin bedrock coal seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

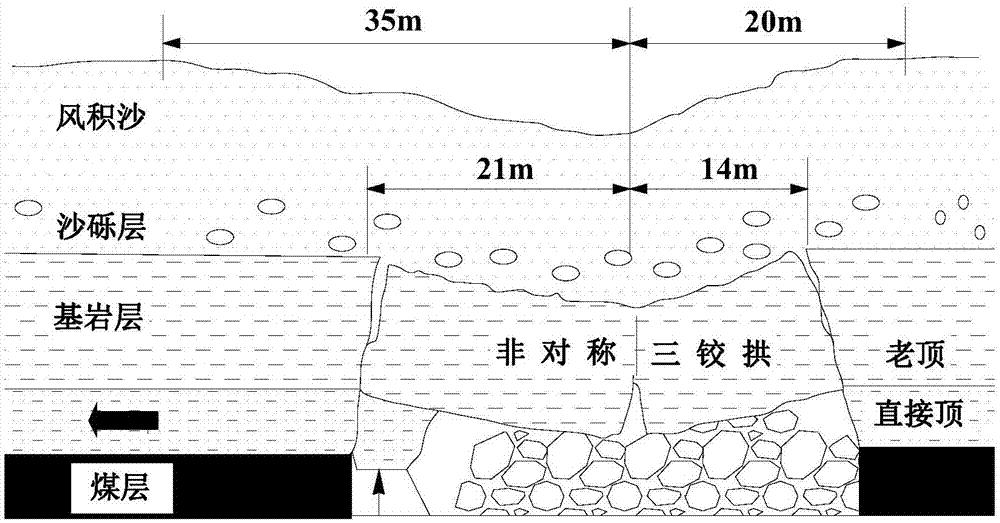

[0175] Bulianta Mine is located in the south of Dongsheng Coalfield, Yikezhao League, Inner Mongolia Autonomous Region. Face 2211, located in the north wing of the second mining area, is the first mining face of the mine. The coal seam has a dip angle of 1°-3°. The texture is hard, and the fissures are extremely undeveloped. The strike length of the working face is 1460m, and the inclination length is 180m. The working face adopts the domestic ZY6000-25 / 50 type two-column shielding hydraulic support, the support width b=1.5m, the support efficiency μ=0.9, and the control distance l k =2.2m, the initial supporting force of the support is 5048kN, and the rated working resistance is 5998kN.

[0176] According to the actual mining conditions of the working face, the parameters are determined as: h=14m; ρg=24kN / m 3 ; h 1 = 40m; ρ 1 g=18kN / m 3 ;Σh=5.8m; m=4.5m; b=1.5m; μ=0.9; l k =2.2m;

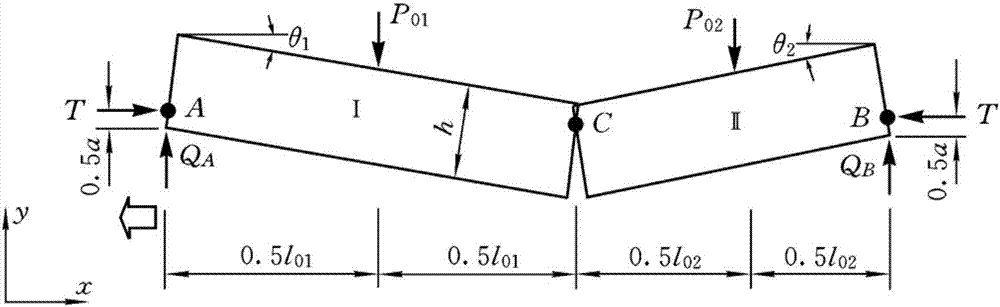

[0177] First, calculate the block length l according to formula (111) 01 : Among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com