Method for purifying and refining L-lactic acid

A refining method and lactic acid technology, which are applied in the preparation of carboxylate, separation/purification of carboxylate compounds, calcium/strontium/barium sulfate, etc., can solve the problem of high processing pressure, poor production environment, and the cost of waste carbon and solid waste treatment. Advanced problems, to achieve the effect of increasing added value, reducing burden, saving equipment investment and auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

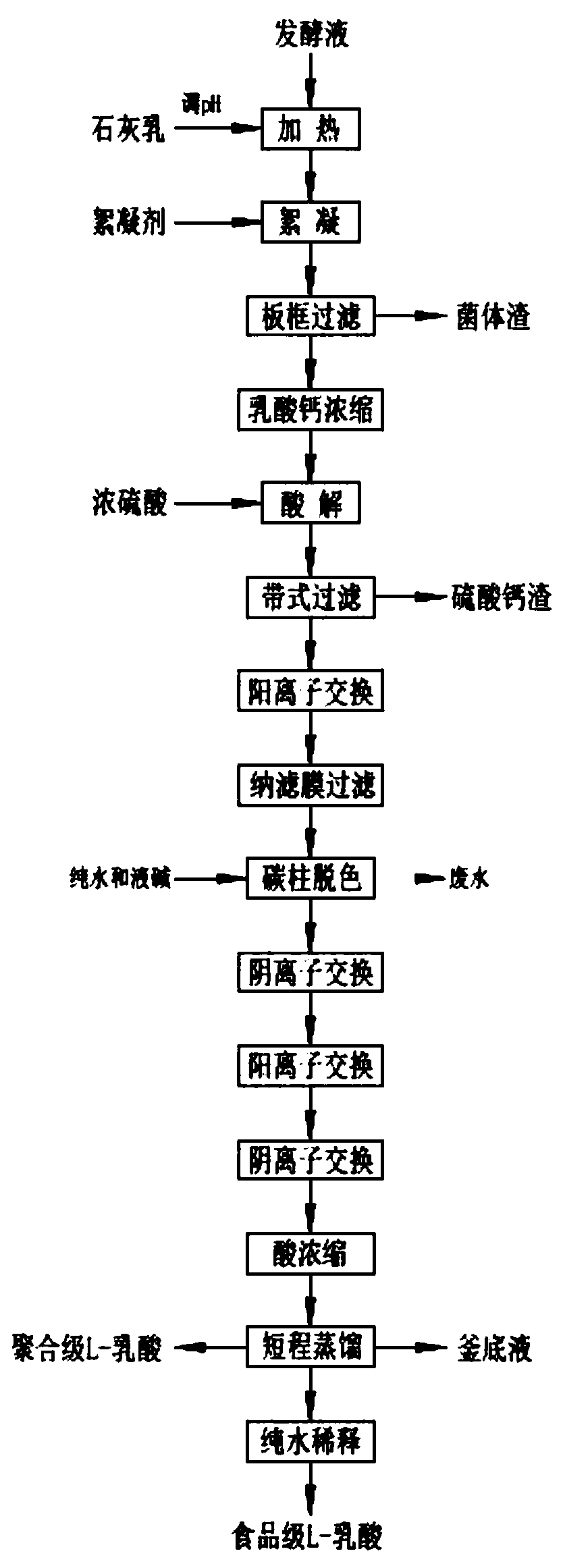

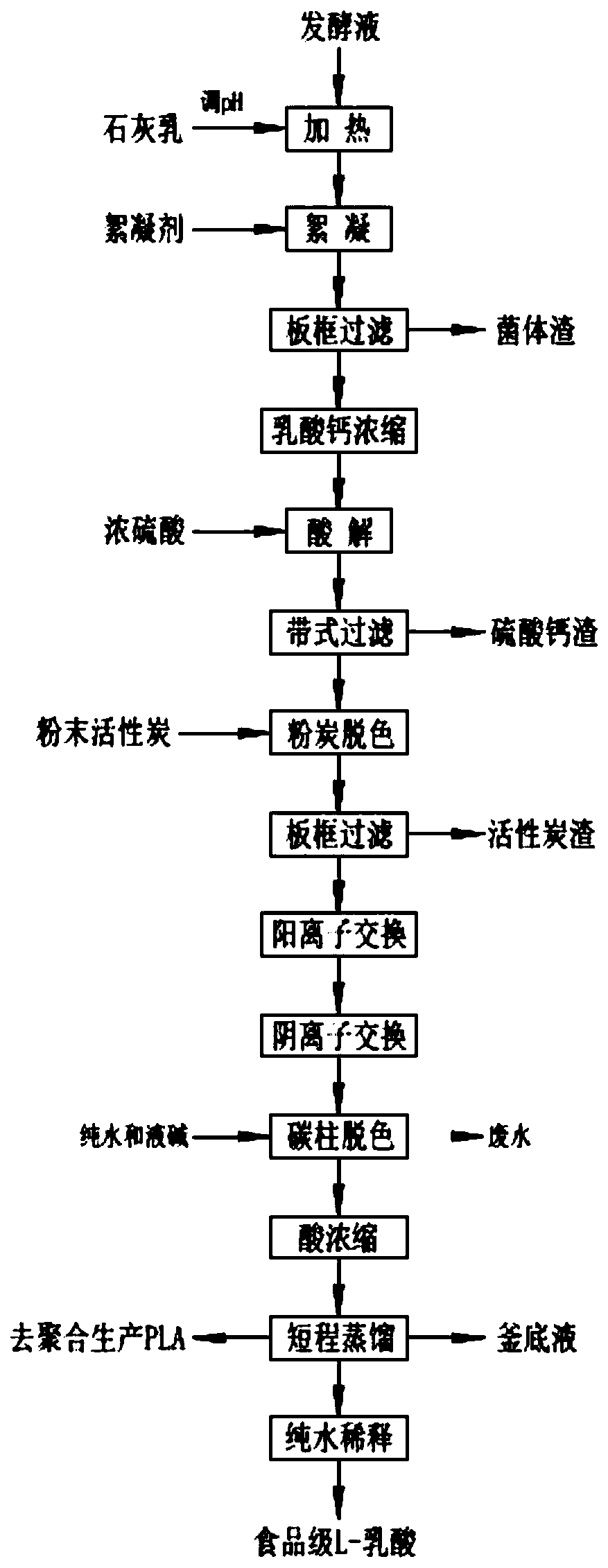

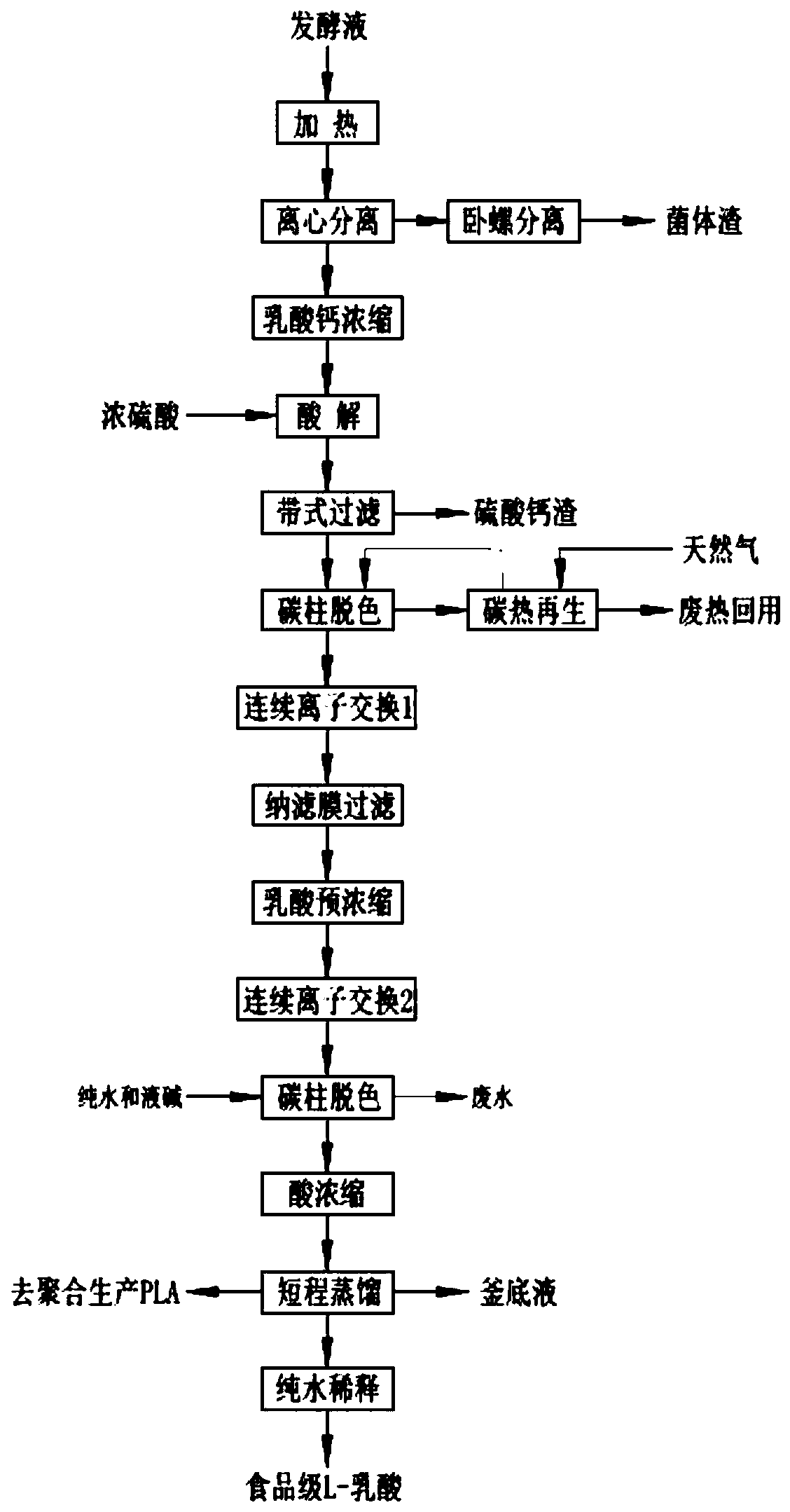

Method used

Image

Examples

Embodiment 1

[0061] Taking an annual output of 10,000 tons of L-lactic acid as an example, using the purification process of the present invention, the steps of the specific purification method in this embodiment are as follows:

[0062] (1) Provide L-lactic acid fermented liquid is 8.669m 3 / h, the L-lactic acid content in the fermentation broth is 16% (mass volume ratio m / v), and the temperature of the fermentation broth is heated from 50°C to 65°C by steam;

[0063] (2) pump the heated fermented liquid obtained in step (1) into the disc centrifuge, the amount of washing water accounts for 17% of the feed amount, the volume content of suspended solids in the light phase is 0.18% v / v, and OD≤2. The heavy phase is continuously processed through the decanter centrifuge to obtain solid slag, the solid content of the solid slag is 51.25%, and the obtained clear liquid is returned to the feed tank of the disc centrifuge;

[0064] (3) The light phase of the disc centrifuge obtained in step (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com