Dry distillation device and dry distillation method of preparing granular nitrogen-free hot gas from crushed bituminous coal and straw

A particle and bituminous coal technology, which is applied in the field of nitrogen-free hot gas carbonization equipment for preparing particles from crushed bituminous coal straw, can solve the problems of large energy loss in re-drying, high cost of tar purification, and cost, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

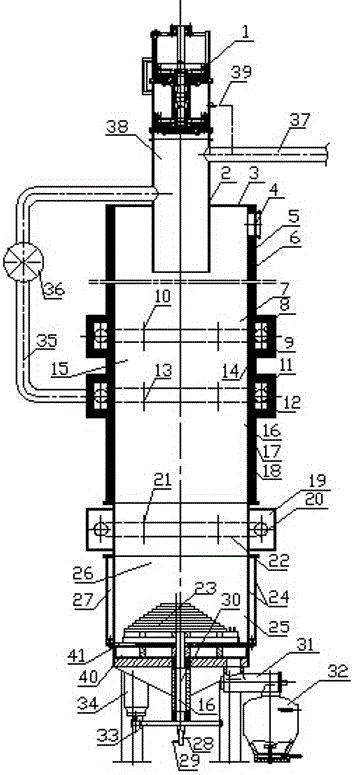

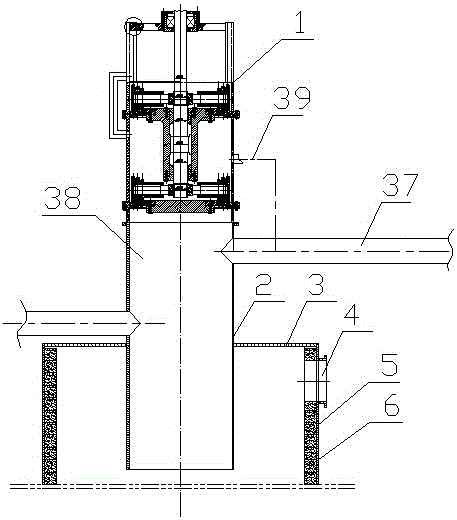

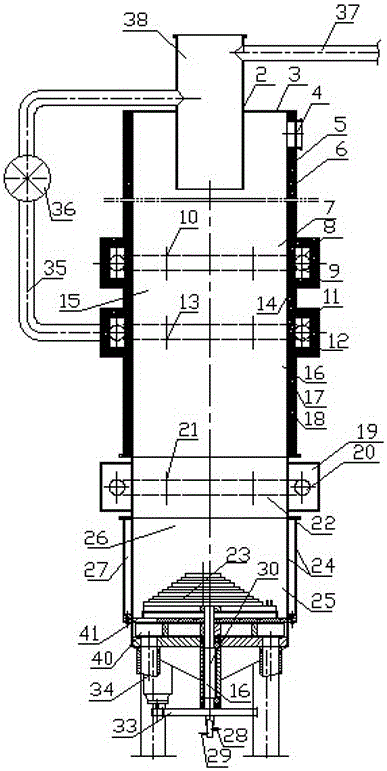

[0026] The nitrogen-free hot gas dry distillation equipment and method for preparing granules from crushed bituminous coal straws of the present invention infiltrate raw materials such as crushed coal, straws, garbage, and sludge with 15-30% of water, and initially roll, knead, and extrude the basic formed powder mud particles, that is, It can be input into the forming cylinder pellet machine 1 and then crushed, kneaded, extruded Φ15-30mm, length 30-200mm cylinder, spherical, diamond-shaped pellets can be input into the material guide cylinder 2 in a mechanically sealed way, or the pellet machine 1 can be set in the semi-coke The upper end of the furnace cover 3 and the extruded particles directly fall into the carbonization chamber 7 in the furnace through the material guide tube 2, and the lower end of the carbonization chamber 7 is connected with a nitrogen-free hot gas chamber 8, and the hot gas chamber 8 generates stable 550- The hot gas at 1150°C passes through the hot ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com