Method for recycling fenton sludge through two-step calcining method

A Fenton sludge and calcination technology, which is applied in the field of water pollution control, can solve the problems of secondary pollution, unfriendly environment, and high cost of Fenton sludge treatment, and achieve the effect of simple operation, environmental friendliness and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

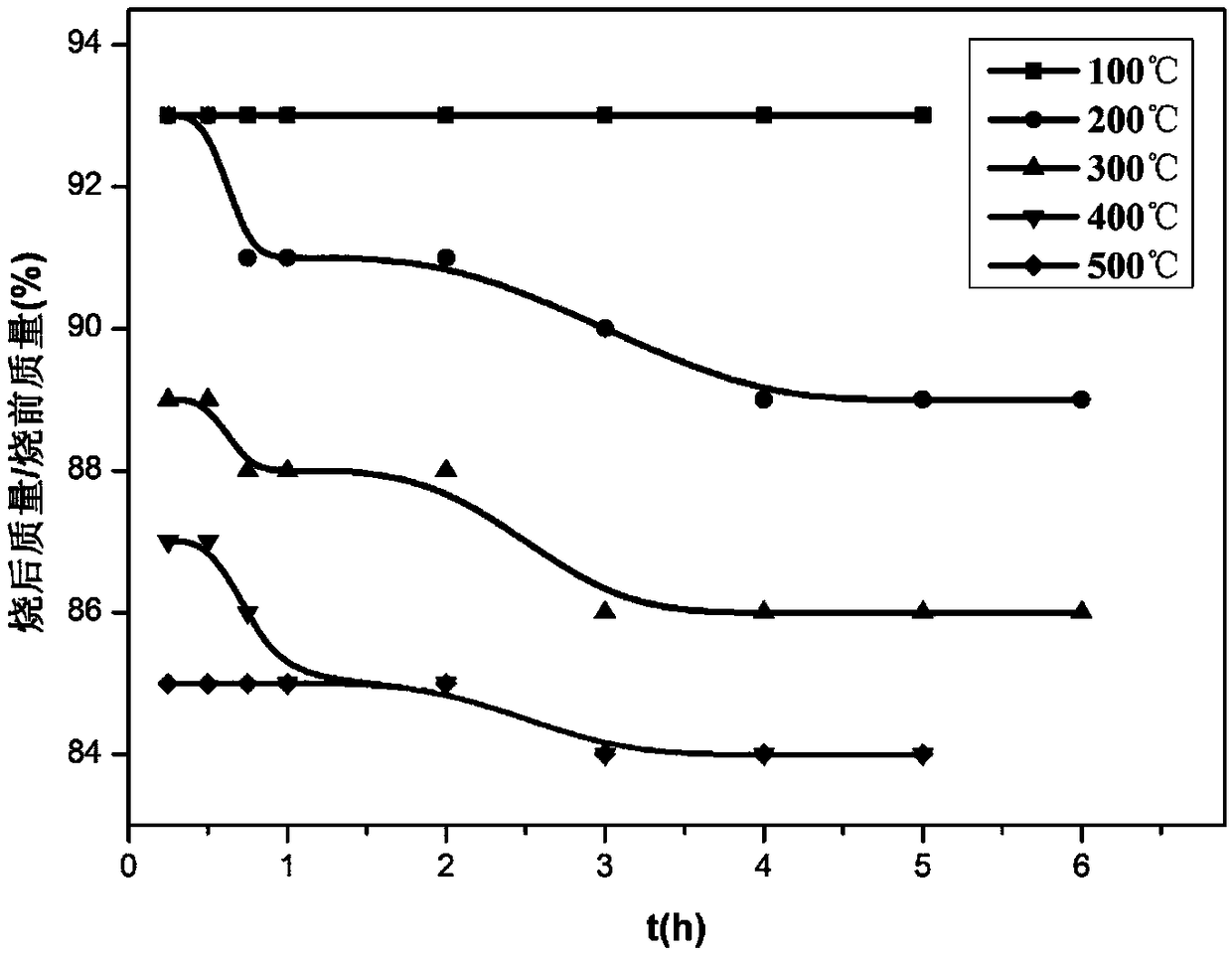

[0027] The present embodiment provides the investigation of the temperature and time of the first calcination of the present invention, specifically as follows:

[0028] Using the Fenton method to treat simulated urotropine wastewater: adjust the pH of the wastewater to 4, and then add 5g / L FeSO 4 and 15g / L of H 2 o 2 , adding alkali after the reaction, adjusting the pH value to 7, and standing for precipitation. The obtained precipitate is Fenton sludge, and its main components are FeOOH and organic matter; the Fenton sludge is dehydrated to a water content of 15wt%.

[0029] Five parts of the dehydrated Fenton sludge were taken, weighed, placed in a muffle furnace, calcined at different temperatures for different times, and weighed. Divide the weight of Fenton's sludge after calcining by the weight of Fenton's sludge before calcining to obtain the weight ratio before and after calcining, so as to investigate the oxidation of organic matter in Fenton's sludge. The results a...

Embodiment 2

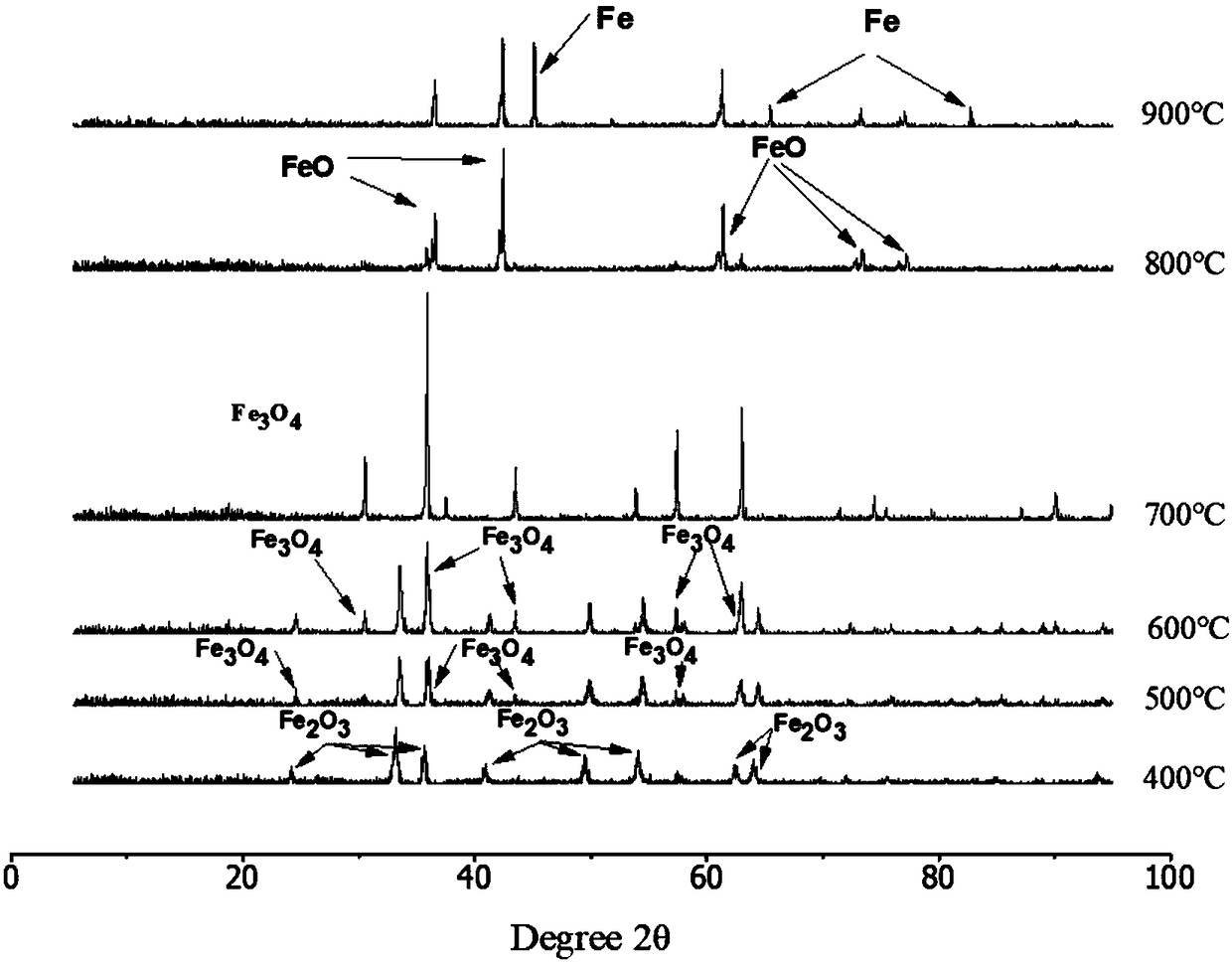

[0038] The present embodiment provides the investigation of the temperature and time of the second calcination of the present invention, specifically as follows:

[0039] Take the first calcined product calcined at 500°C for 5 hours and carbon powder in Example 1 and mix them evenly in a mass ratio of 84:16, divide them into 5 parts, put them into tube furnaces respectively, and heat them at different temperatures Calcined under different conditions for different times to obtain the second calcined product, the 5 parts of the second calcined product were analyzed by X-ray diffractometer respectively, the results are shown in the attached figure 2 As shown, namely:

[0040] When the calcination temperature is lower than 500°C, the iron of the second calcined product is Fe 2 o 3 exists in the form of

[0041] When the calcination temperature was 500°C, a small amount of Fe began to appear in the second calcined product 3 o 4 ;

[0042] When the calcination temperature is ...

Embodiment 3

[0048] The present embodiment provides the method that the two-step calcination method of the present invention reclaims Fenton's sludge, specifically:

[0049] Using the Fenton method to treat simulated urotropine wastewater: adjust the pH of the wastewater to 4, and then add 5g / L FeSO 4 and 15g / L of H 2 o 2, add alkali after the reaction, adjust the pH value to 7, let it stand for precipitation, the obtained sediment is Fenton sludge, and its main components are FeOOH and organic matter;

[0050] Dewatering the Fenton sludge to a water content of 15 wt%;

[0051] The dehydrated Fenton sludge is placed in a muffle furnace, and calcined at 500° C. for 3 hours, the calcined carbon dioxide and water are discharged, and the solid obtained by calcining is the first calcined product. After the first calcination, the organic matter in the Fenton sludge has been completely oxidized to generate carbon dioxide and water, and the main component of the first calcined product is Fe pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com