Method for comprehensively utilizing magnesium and iron in nickel laterite ore

A technology of laterite nickel ore and ferromagnesia, which is applied in the direction of magnesia and improvement of process efficiency, can solve the problems of high leaching residual acid, loss, and insufficient nickel leaching rate, and achieve good sealing performance, offset production costs, and high concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

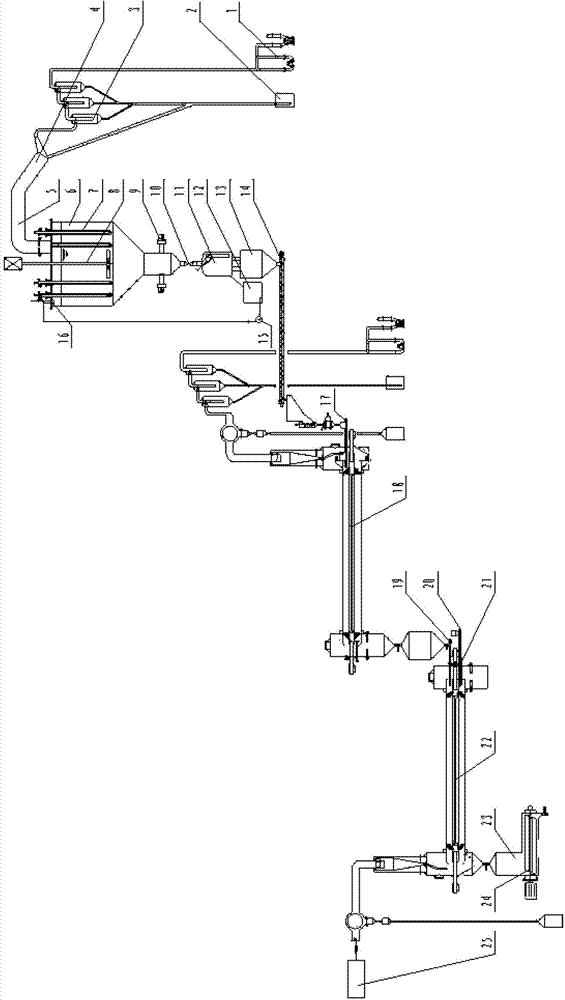

Image

Examples

Embodiment Construction

[0025] The method for the comprehensive recovery and utilization of ferromagnesia in the laterite nickel ore of the present invention, the specific operation steps are as follows:

[0026] The ore of laterite nickel ore is intensified leached with sulfuric acid to obtain an intensified leaching solution, which uses magnesite or brucite or other magnesium-containing materials as a neutralizing agent to remove iron. In the one-stage iron removal method, since magnesite or brucite or other magnesium-containing materials contain slag, the iron removal slag is temporarily stored or used for other purposes. When the aluminum content of the laterite nickel ore is low, the second-stage iron removal slag is repeatedly used as a neutralizer for the first-stage iron removal to dissolve the aluminum and wash the entrained nickel to reduce the nickel content in the iron slag. When more aluminum is accumulated, the iron removal slag in the second stage is kept for separate aluminum and iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com