Method for producing formic acid through phosphoric acid and sodium formate

A technology of sodium formate and sodium dihydrogen phosphate, applied in carboxylate preparation, organic chemistry, etc., can solve problems such as environmental pollution, achieve the effects of protecting the environment, convenient operation, and promoting comprehensive utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

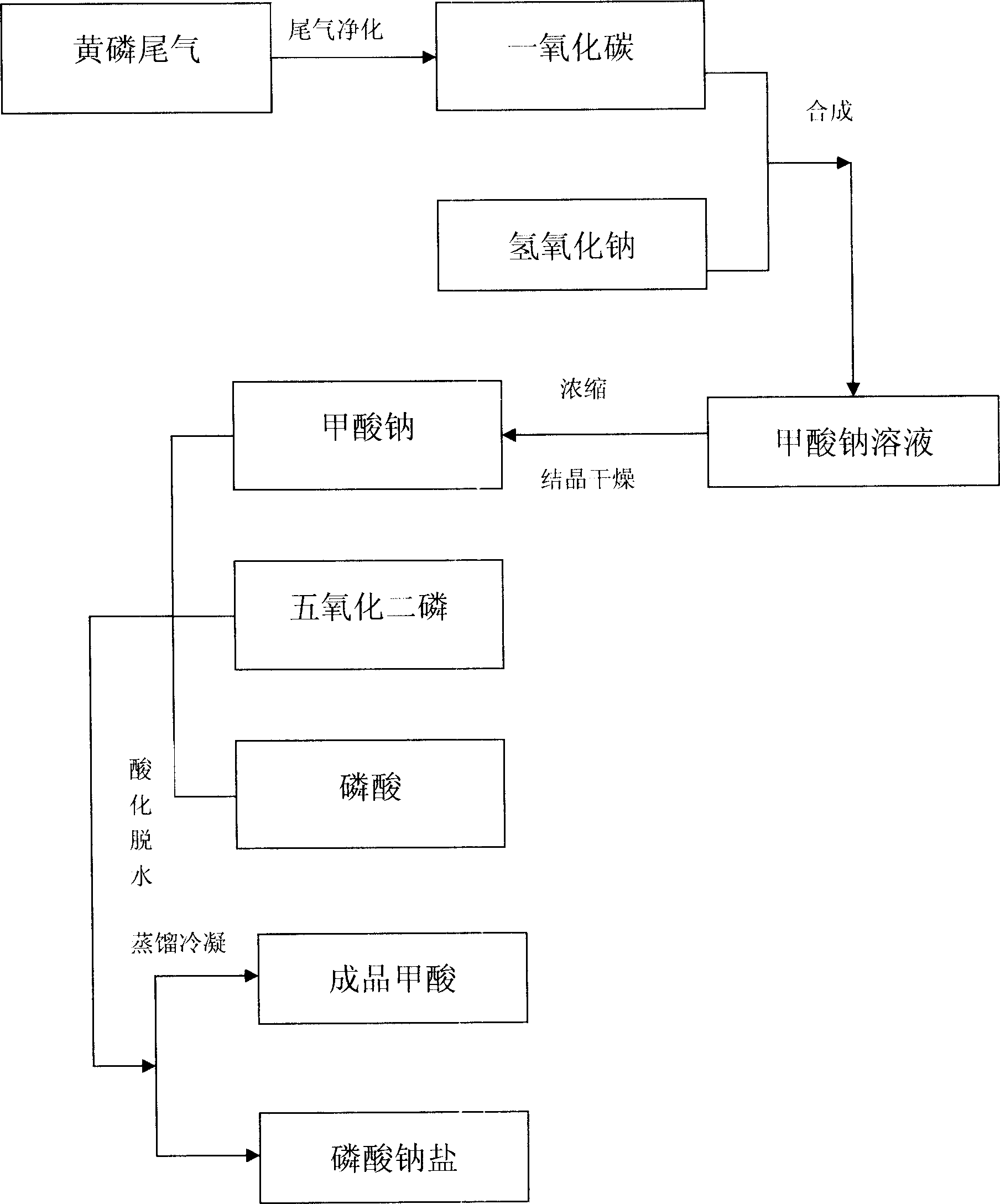

[0014] Such as figure 1 As shown, using the carbon monoxide tail gas in the production of yellow phosphorus as raw material, through purification and desulfurization treatment, the carbon monoxide obtained is synthesized with caustic soda, concentrated crystallization, separation, and drying to obtain sodium formate; first add 600Kg of phosphoric acid in the reactor, and then Then add 600Kg of sodium formate, control the reaction temperature at 40°C, and react under the action of stirring to obtain a solution of formic acid and sodium dihydrogen phosphate, which enters the evaporator through the outlet at the bottom of the reactor. Add 180Kg of phosphorus pentoxide to the top of the tank to remove the water in the solution. After stirring evenly, heat with steam and carry out distillation. Control the distillation temperature at 110°C. The gas phase enters the cooler and is cooled with tap water. The distillate after cooling is For formic acid, the liquid phase is sodium dihyd...

Embodiment 2

[0017] Such as figure 1 As shown, using the carbon monoxide tail gas in the production of yellow phosphorus as raw material, through purification and desulfurization treatment, the carbon monoxide obtained is synthesized with caustic soda, concentrated crystallization, separation, and drying to obtain sodium formate; first add 760Kg of phosphoric acid in the reactor, and then Then add 650Kg of sodium formate, control the reaction temperature at 50°C, and react under the action of stirring to obtain a solution of formic acid and sodium dihydrogen phosphate, which enters the evaporator through the outlet at the bottom of the reactor. Add 200Kg of phosphorus pentoxide to the top of the tank to remove the water in the solution. After stirring evenly, heat with steam and carry out distillation. Control the distillation temperature at 130°C. The gas phase enters the cooler and is cooled with tap water. The distillate after cooling is For formic acid, the liquid phase is sodium dihyd...

Embodiment 3

[0020] Such as figure 1 As shown, using the carbon monoxide tail gas in the production of yellow phosphorus as raw material, through purification and desulfurization treatment, the carbon monoxide obtained is synthesized with caustic soda, concentrated crystallization, separation, and drying to obtain sodium formate; first add 800Kg of phosphoric acid in the reactor, and then Then add 700Kg of sodium formate, control the reaction temperature at 45°C, and react under the action of stirring to obtain a solution of formic acid and sodium dihydrogen phosphate, which enters the evaporator through the outlet at the bottom of the reactor. Add 220Kg of phosphorus pentoxide to the top of the tank to remove the water in the solution. After stirring evenly, heat with steam and carry out distillation. Control the distillation temperature at 140°C. The gas phase enters the cooler and is cooled with tap water. The distillate after cooling is For formic acid, the liquid phase is sodium dihyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com