Method for preparing lactic acid by applying double pole film electrodialysis technique

A technology of bipolar membrane electrodialysis and electrodialyzer, applied in the field of preparation of lactic acid using bipolar membrane electrodialysis technology, can solve the problems of product loss cost, loss, increase, etc., and achieve significant industrial application value and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

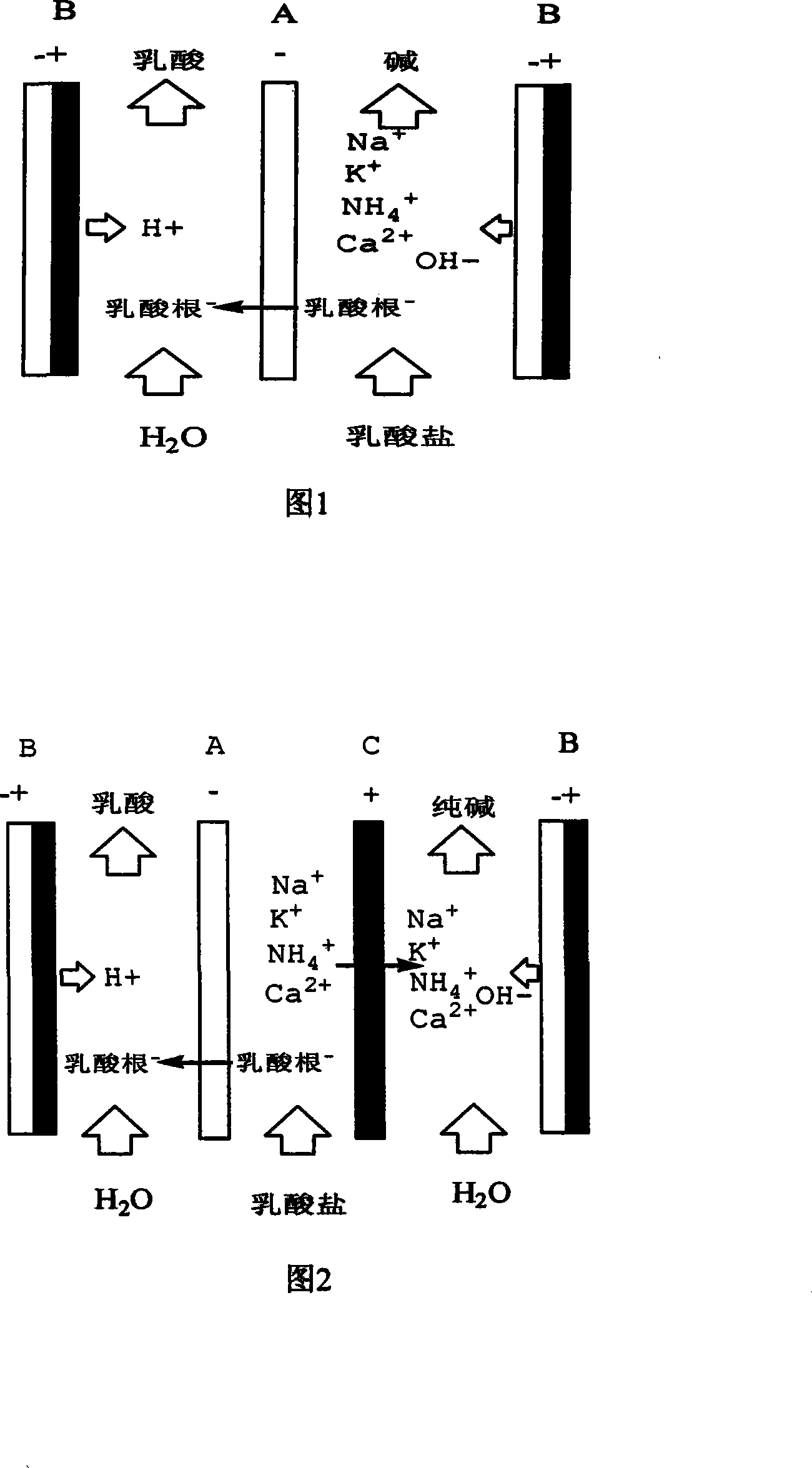

[0017] Pump 2L of the pretreated lactic acid fermentation broth (with a lactate content of 1.5mol / L) at a rate of 70L / h into the salt chamber of the salt / acid two-chamber electrodialyzer (Figure 1). Then pump 0.6L of lactic acid solution with an initial concentration of 0.2mol / L into the acid chamber at a rate of 60L / h to increase the conductivity of the acid chamber solution. Control the voltage so that the current density is maintained at 160mA / cm 2 , the operating temperature is 60°C, the reaction is 4 hours, the conversion rate of lactate reaches 95%, the energy consumption is 2.6kW·h / kg, the current efficiency is about 80%, and the recovery rate of lactic acid can reach 90%.

Embodiment 2

[0019] Pump 2L of pretreated lactic acid fermentation broth (1.5mol / L lactate content) at a rate of 100L / h into the salt chamber of the acid / salt / alkali three-chamber electrodialyzer (Figure 2). Then pump 1L of lactic acid solution with an initial concentration of 0.2mol / L into the acid chamber at a rate of 60L / h, and 1L of NaOH solution with an initial concentration of 0.1mol / L into the alkali chamber at a rate of 70L / h to increase the acid-base The conductivity of the solution in each chamber. Control the voltage so that the current density is maintained at 80mA / cm 2 , the operating temperature is 40°C, the reaction is 6 hours, the conversion rate of lactate reaches 97%, the energy consumption is 5.5kW·h / kg, the current efficiency is 90%, and the recovery rate of lactic acid can reach 90%.

Embodiment 3

[0021] The method is the same as in Example 1, except that the electrodialyzer is assembled between a pair of electrodes and three membrane repeating units shown in Figure 1 form a plurality of compartments, and the compartments are combined into an anode compartment-acid compartment - salt chamber - acid chamber - salt chamber - acid chamber - salt chamber - cathode chamber. The acid chambers were perfused with lactic acid solution with an initial concentration of 0.2mol / L at a flow rate of 80L / h to increase the conductivity of the acid chamber solution. The salt chambers were perfused with fermentation broth with a lactate content of 1.5 mol / L at a flow rate of 100 L / h. Control the voltage so that the current density is maintained at 160mA / cm 2 , the operating temperature is 25°C, the reaction is 6 hours, the conversion rate of lactate reaches 94%, the energy consumption is 3.2kW·h / kg, the current efficiency is about 80%, and the recovery rate of lactic acid can reach 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com