A method of recovering and utilizing salt lake lithium extraction mother liquor and producing a by-product basic magnesium carbonate

A technology for extracting lithium mother liquor and lithium mother liquor from salt lakes, which is applied in the direction of lithium carbonate; Benefits and economic benefits, the effect of improving recycling rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

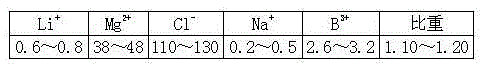

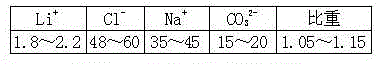

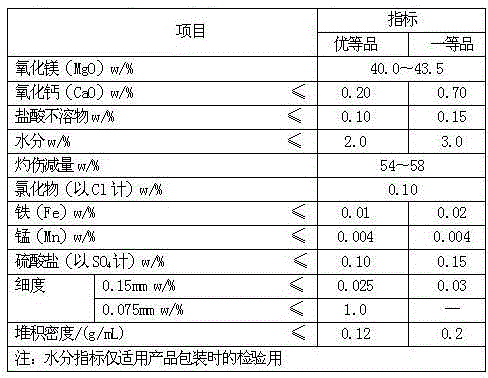

Embodiment 1

[0028] (1) Lithium Extraction Mother Liquor 1 is the tail liquid produced in the separation process of magnesium and lithium in brine with a high magnesium-lithium ratio raw material. The contents of lithium and magnesium in the tail liquid are respectively: Li + The content is 0.6g / L, Mg 2+ The content is 38g / L, and the mother liquor 2 is the tail liquid produced in the conversion lithium precipitation process, which contains 2.2g / L Li + In addition to ions, it also contains 15g / L of CO 3 2- ions and 80g / L NaCl, the temperature of mother liquor 1 is between 25°C and the temperature of mother liquor 2 is between 85°C, mix mother liquor 2 and mother liquor 1 at a ratio of 6:1, and the temperature of the solution after mixing is between 50°C , after mixing, stir the reaction for 25 minutes, CO in the mother liquor 1 3 2- Ions and Mg in Mother Liquor II 2+ Basic magnesium carbonate is formed, and crude basic magnesium carbonate is obtained after pressure filtration and separ...

Embodiment 2

[0033] (1) Lithium Extraction Mother Liquor 1 is the tail liquid produced in the separation process of magnesium and lithium in brine with a high magnesium-lithium ratio raw material. The contents of lithium and magnesium in the tail liquid are respectively: Li + The content is 0.7g / L, Mg 2+ The content is 43g / L, and the mother liquor 2 is the tail liquid produced in the conversion lithium precipitation process, which contains 2.0g / L Li + In addition to ions, it also contains 17g / L of CO 3 2- ions and 90g / L NaCl, the temperature of mother liquor 1 is 30°C, the temperature of mother liquor 2 is 90°C, mix mother liquor 2 and mother liquor 1 at a ratio of 5:1, the temperature of the solution after mixing is 55°C, stir and react for 25 minutes, CO in mother liquor 3 2- Ions and Mg in Mother Liquor II 2+ Basic magnesium carbonate is formed, and crude basic magnesium carbonate is obtained after pressure filtration and separation, and the mother liquor needs to be further proces...

Embodiment 3

[0038] (1) Lithium Extraction Mother Liquor 1 is the tail liquid produced in the separation process of magnesium and lithium in brine with a high magnesium-lithium ratio raw material. The contents of lithium and magnesium in the tail liquid are respectively: Li + The content is 0.8g / L, Mg 2+ The content is 48g / L, and the mother liquor 2 is the tail liquid produced in the conversion lithium precipitation process, which contains 1.8g / L Li + In addition to ions, it also contains 20g / L CO 3 2- ions and 100g / L NaCl, the temperature of mother liquor 1 is 35°C, the temperature of mother liquor 2 is 95°C, mix mother liquor 2 and mother liquor 1 at a ratio of 4:1, the temperature of the solution after mixing is 60°C, stir and react for 25 minutes, CO in mother liquor 3 2- Ions and Mg in Mother Liquor II 2+ Basic magnesium carbonate is formed, and crude basic magnesium carbonate is obtained after pressure filtration and separation, and the mother liquor needs to be further processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com