Mechanical and plant purification system for artificial culturing tail water

A plant purification and tail water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of filter layer failure, filter efficiency reduction, and filter effect drop, etc. Achieve the effects of good filtering effect, high utilization rate of equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

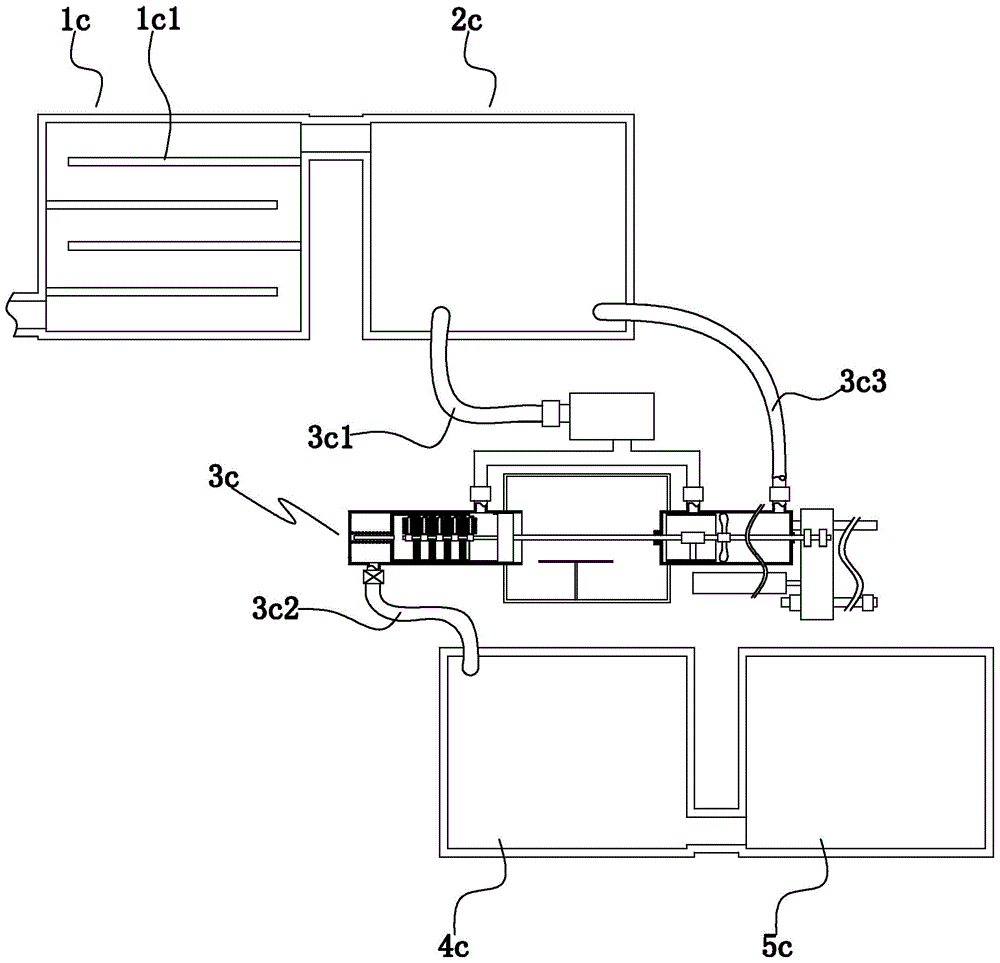

[0042] Such as figure 1 As shown, a mechanical and plant purification system for artificial culture tail water includes a sedimentation tank 1c, an aeration tank 2c, a mechanical filtration device 3c, an algae purification tank 4c and an ozone disinfection tank 5c. In the sedimentation tank, several partition walls 1c1 are arranged to divide the sedimentation tank into tortuous water flow channels. There is an aeration device at the bottom of the aeration tank. The algae purification pond in this embodiment is a spirulina purification pond or a chlorella purification pond or a Synechococcus purification pond or a salina purification pond or a Phaeodactylum purification pond.

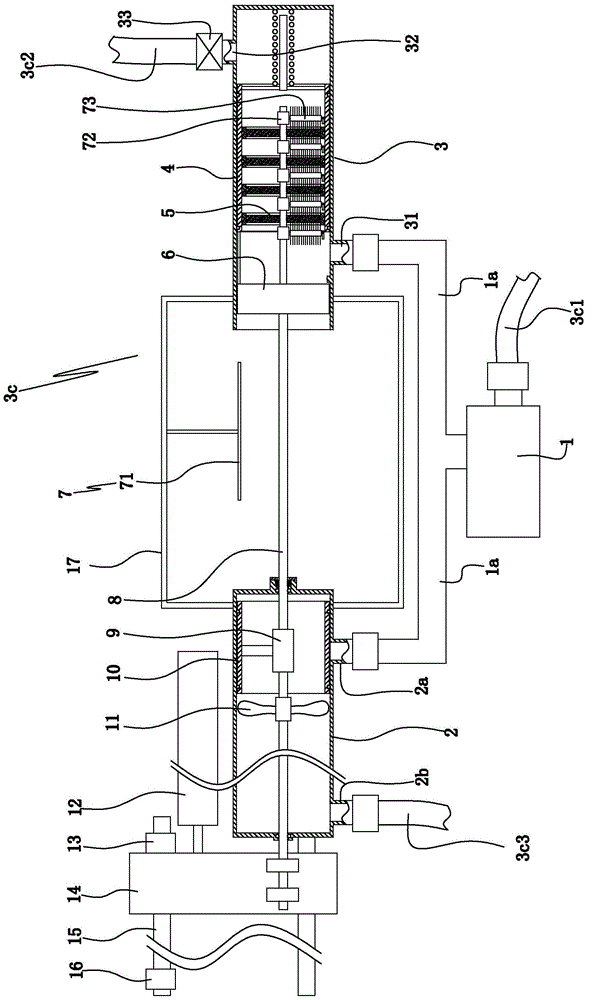

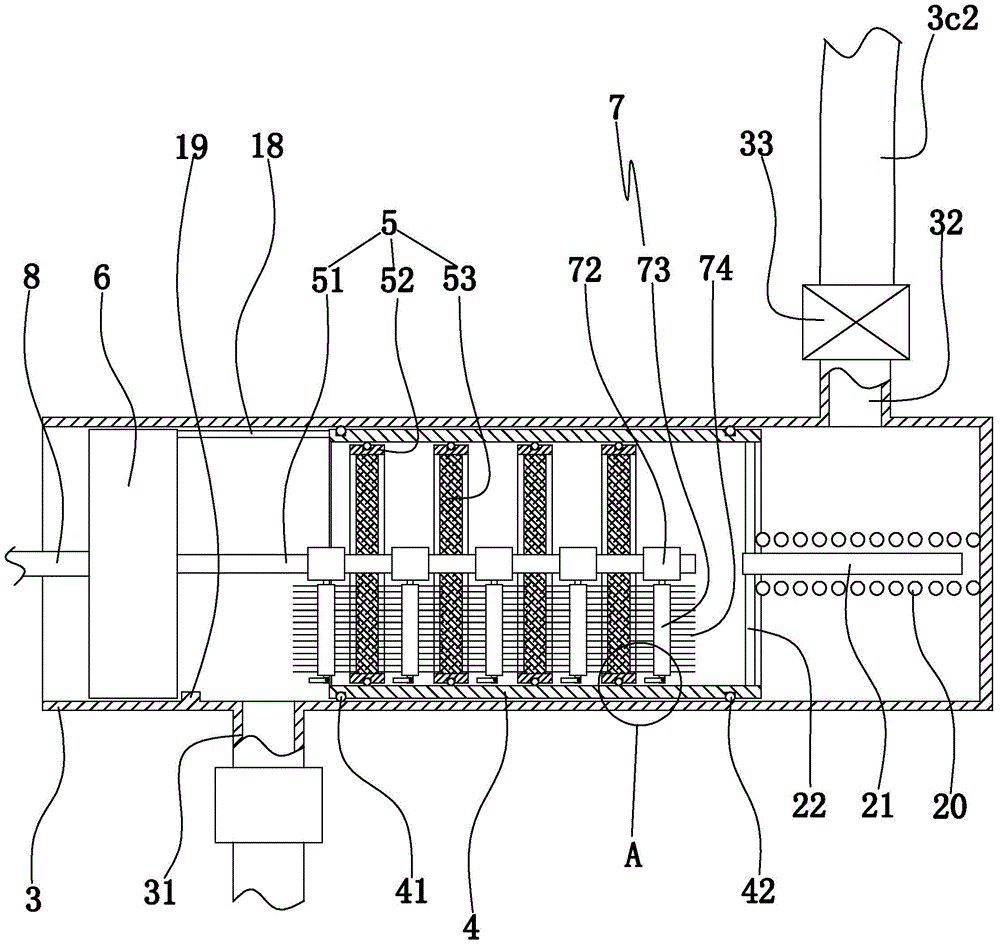

[0043] Such as figure 2 As shown, the mechanical filtering device 3c includes a frame, a garbage collection bucket 17 with an upper end opening, a water suction pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com