Method for producing N-alkyl substituted phosphoric triamide

A technology for the production of phosphoric triamides, applied in chemical instruments and methods, phosphate fertilizers, organic phosphate fertilizers, etc., can solve the problems of unfavorable purification of final products, high requirements for production conditions, cumbersome operation steps, etc., and achieve simple solvent recovery process, The product purity and yield are improved, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

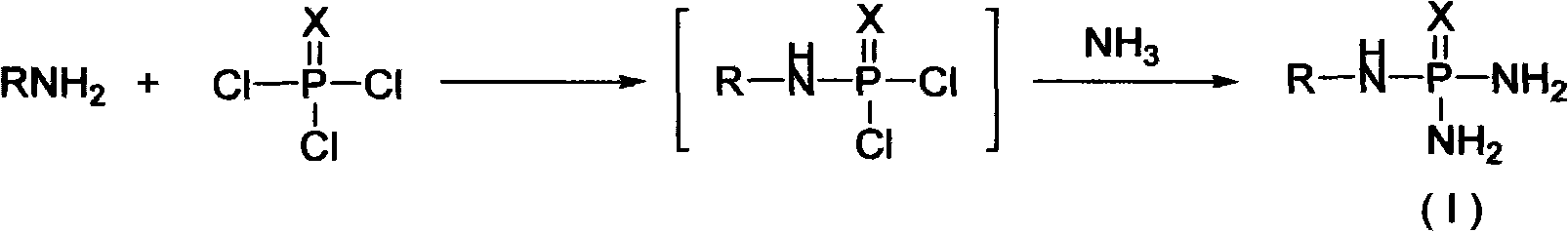

Method used

Image

Examples

Embodiment 1

[0016] The production process in the No. 1 reactor:

[0017] The No. 1 reactor is a mechanically stirred tank, and the stirring speed of the No. 1 reactor is controlled at 20rpm to 60rpm. The heat exchange device used is a reflux cooling device, and the cooling medium is water, ice water or calcium chloride freezing liquid.

[0018] In Reactor No. 1, mix and match 1L to 1.6L of solvent according to 1 mole of chlorine phosphorus solution, and add 50Kg of PSCl 3 , 384Kg of CH 2 Cl 2 , mixed and stirred at a speed of 30rpm until the temperature was cooled to 5-15°C, and the alkylamine was added dropwise.

[0019] According to the molar ratio range of chlorophosphorus solution to alkylamine in the range of 1:1.95 to 1:2.1, 43.3Kg of n-butylamine is dropped into the cooled feed liquid, and excess n-butylamine is used as an acid-binding agent. Control the rate of addition to keep the temperature of the reaction system at 10-12°C. After the dropwise addition is completed, the rea...

Embodiment 2

[0031] The production process in the No. 1 reactor:

[0032] This No. 1 reaction kettle is a magnetic stirring tank, and the heat exchange device used is a reflux cooling device, and the cooling medium therein is water, and ice water can also use calcium chloride freezing liquid.

[0033] Add 50Kg of PSCl in No. 1 reactor 3 , 384Kg CH 2 Cl 2 , stirred and cooled to 10°C, added dropwise 45.3Kg of n-hexylamine, and controlled the rate of addition to keep the temperature of the reaction system at 10-15°C. After the dropwise addition was completed, the reaction system was heated under normal pressure to reflux state, refluxed for 1 hour, cooled, added 50 L of water and stirred at 20 rpm for 15 minutes, left to separate for about 2 hours, and the aqueous phase and the organic phase were separated.

[0034] The organic phase was dried over anhydrous sodium sulfate and put into No. 2 reaction kettle for later use.

[0035] The production process in the No. 2 reactor:

[0036] Un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com