Ultrafine fiber based on recycled polyester and production method thereof

A technology of ultra-fine fiber and regenerated polyester, applied in the direction of single-component polyester rayon filament, conjugated synthetic polymer rayon filament, etc., which can solve the problem of poor strength of fine denier fibers and inability to use ultra-fine fibers for direct spinning , poor performance of recycled polyester, etc., to achieve the effect of improving product competitiveness, low raw material prices, and low fiber fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the preparation process of the product of the present invention, the raw materials and methods in the fiber material obtained by the two-component spinning machine and the stripping process by the alkali hydrolysis method all belong to the technical content known to those skilled in the art and production personnel, so in the specific examples This part is omitted.

[0030] The two-component spinning machine is not limited in the following examples because although the manufacturers and models of the two-component spinning machines are different, they do not affect the preparation of the ultrafine fibers.

Embodiment 1

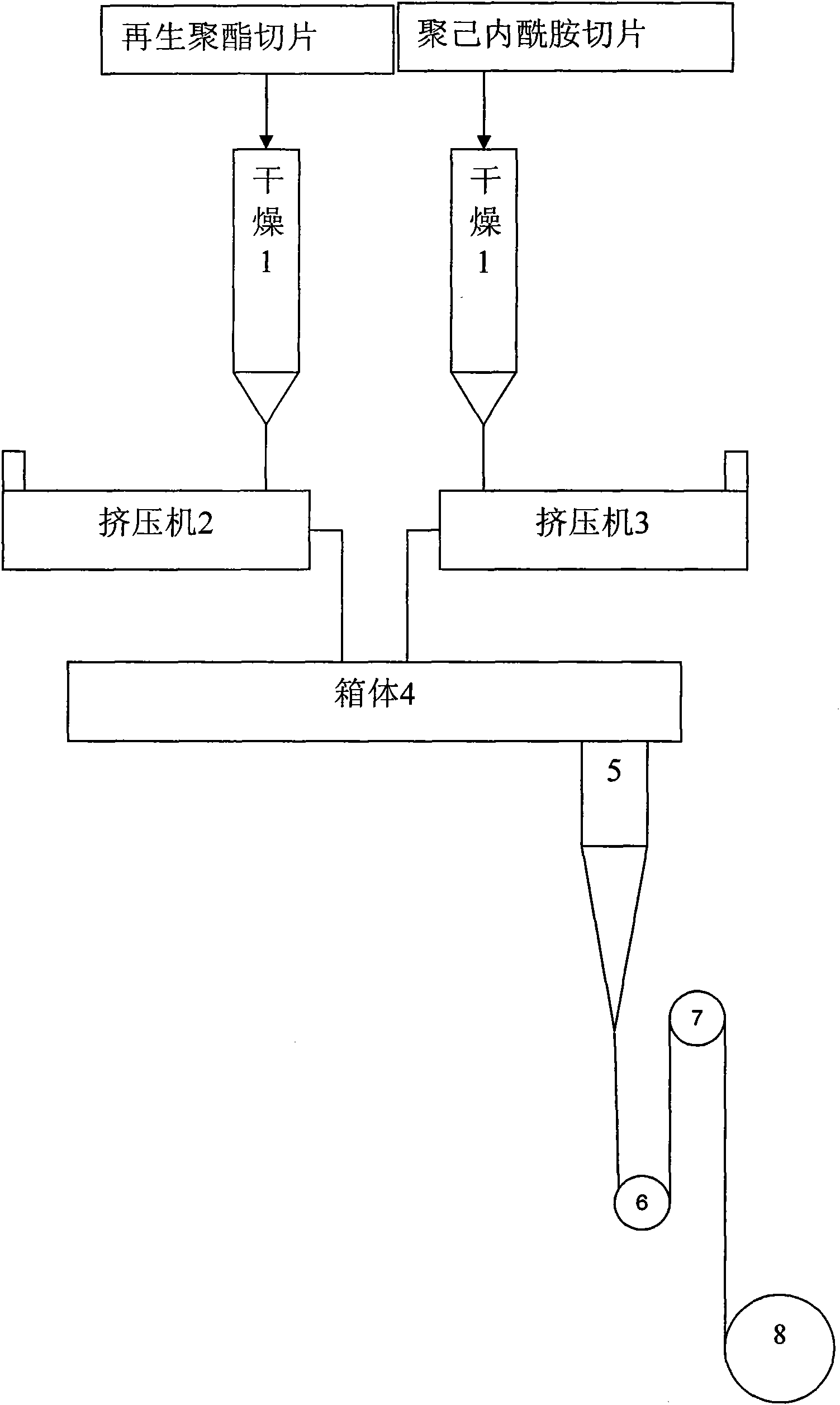

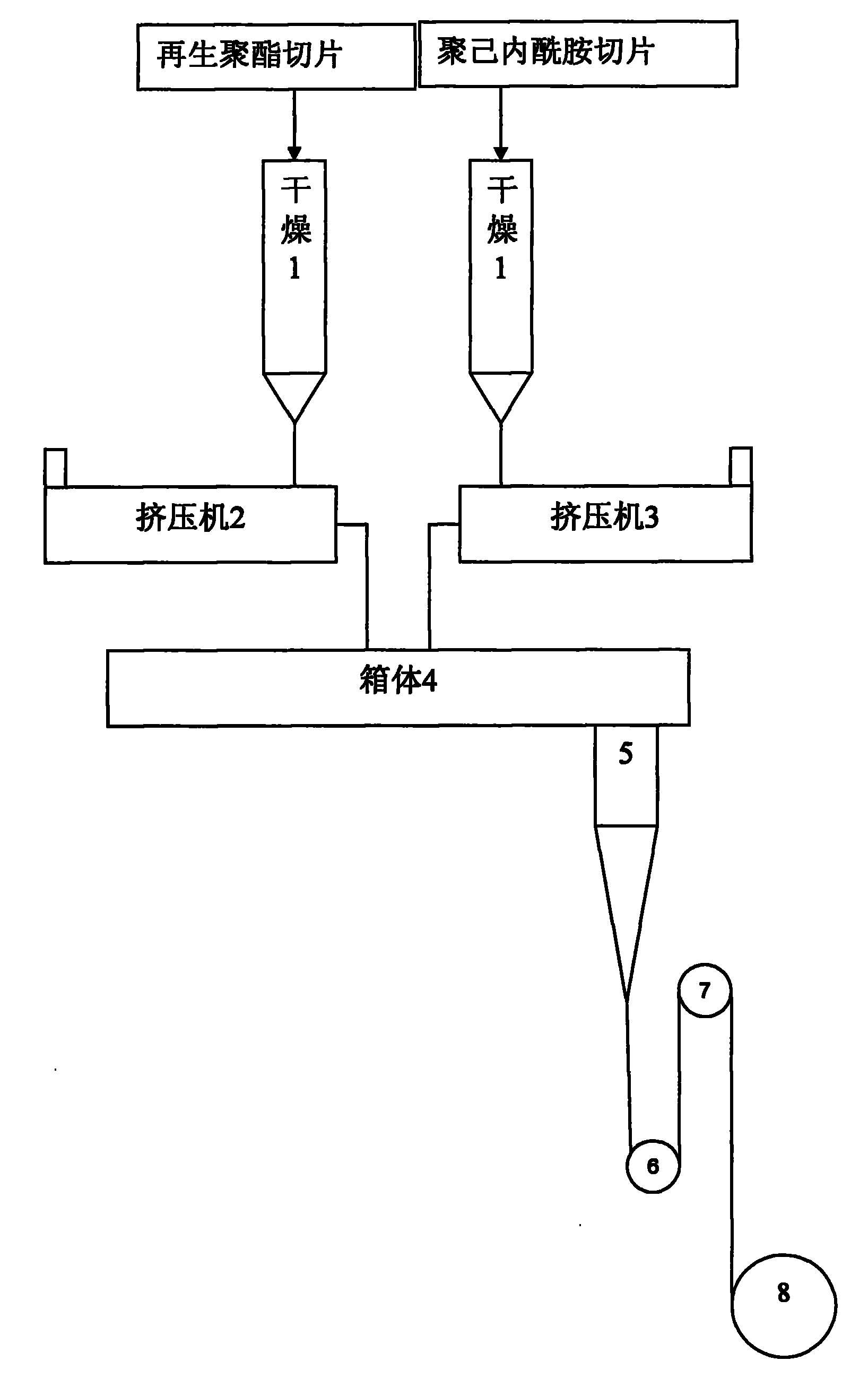

[0032] Referring to the accompanying drawings, the present invention is based on ordinary bicomponent fiber production equipment for the production of recycled polyester superfine fiber POY, which is respectively made of recycled polyester beverage bottles that are shredded, dried, and then granulated for granulation. Ester chip A and polycaprolactam chip B are raw materials (the intrinsic viscosity of recycled polyester chip A is 0.695, and the intrinsic viscosity of polycaprolactam chip B is 2.4), and the two raw materials of recycled polyester chip A and polycaprolactam chip B are crystallized and dried After machine 1 is dried, it is extruded and melted by the first extruder 2 and the second extruder 3 respectively, and then sent to the compound spinning box 4, and is precisely metered and extruded by the heat-preserved spinning metering pump, and distributed to each compound spinning box. In the assembly, after extrusion, it is cooled by side blowing to form, the oil nozzl...

Embodiment 2

[0037]Referring to the accompanying drawings, the present invention is based on common two-component fiber production equipment for the production of recycled polyester microfiber POY, which consists of regenerated polyester chips C obtained by cleaning, sorting and shredding recycled polyester beverage bottles. and polycaprolactam chip B as raw materials (the intrinsic viscosity of recycled polyester chip C is 0.736, and the intrinsic viscosity of polycaprolactam chip B is 2.4), and the two raw materials of recycled polyester chip C and polycaprolactam chip B are dried by crystallization dryer 1 Finally, they are extruded and melted by the first extruder 2 and the second extruder 3 respectively, and then sent to the composite spinning box 4, and are precisely metered and extruded by the heat-preserved spinning metering pump, and distributed to each composite spinning assembly. After being extruded, it is cooled by side air blowing and formed, the oil nozzle 5 is oiled, guided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com