Technique for purifying acetylene gas with sulfuric acid and application thereof

A technology for acetylene gas and sulfuric acid, applied in absorption purification/separation, hydrogen halide addition preparation, organic chemistry, etc., can solve problems such as ignoring the water absorption of concentrated sulfuric acid, and achieve the effect of reducing equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Taking acetylene gas as an example in the vinyl chloride synthesis process, the technical solution of the present invention will be described in detail below.

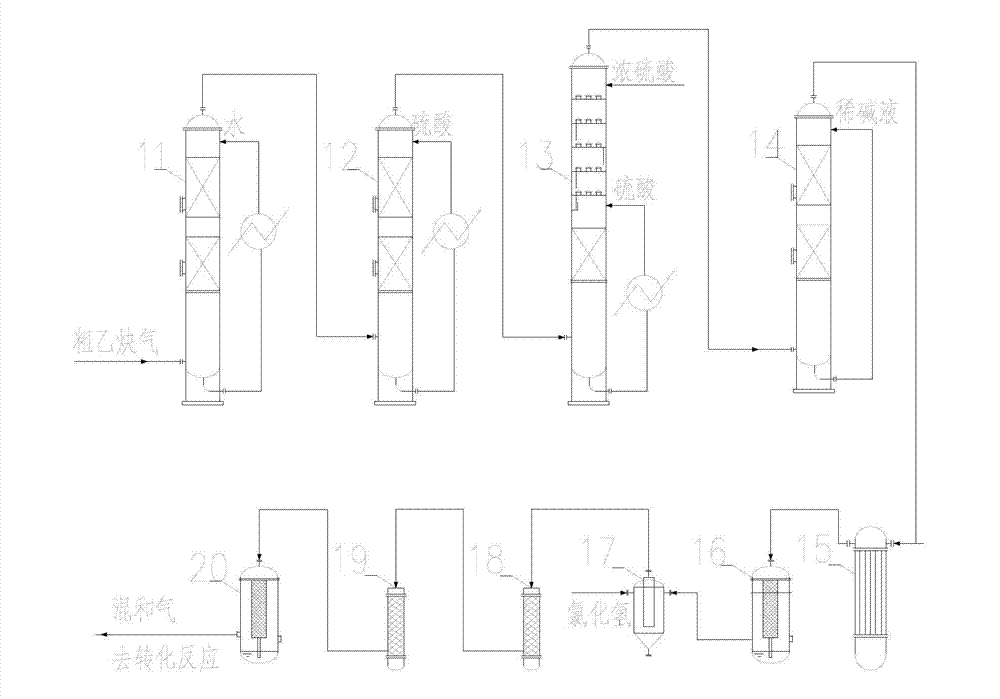

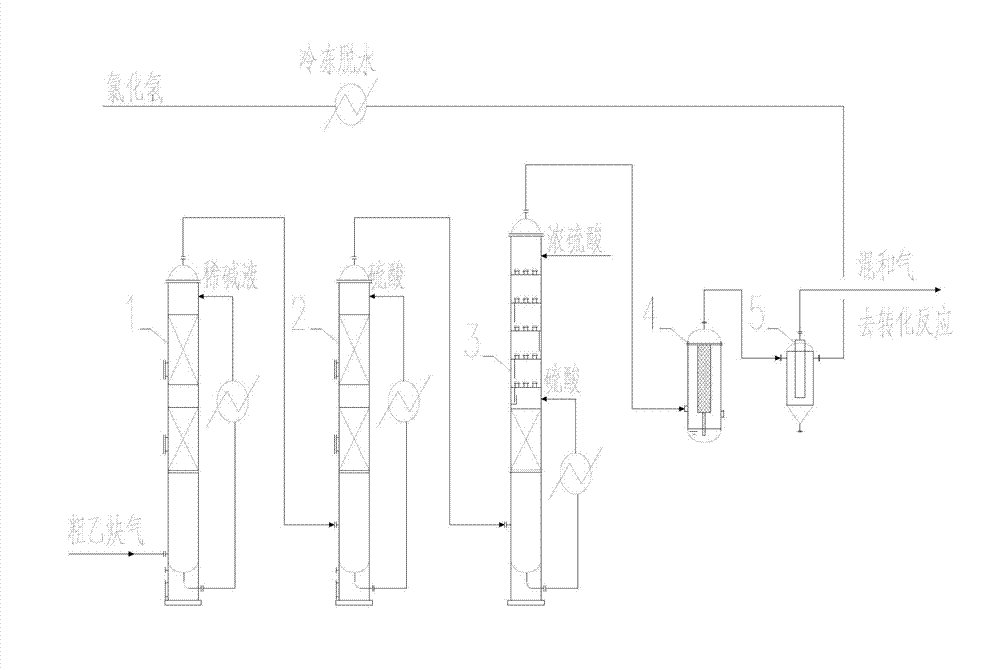

[0024] The traditional process of cleaning acetylene gas with sulfuric acid such as figure 1 As shown, the acetylene gas compressed by the acetylene compressor at a temperature of 40°C and containing saturated water vapor first enters the second washing tower 11 and is cooled to 20°C, and then enters the two-stage sulfuric acid cleaning tower: the sulfuric acid washing tower 12 and the sulfuric acid cleaning tower 13 , after removing the sulfur and phosphorus therein, it enters the alkali washing tower 14 for alkali washing; after that, the acetylene gas is cooled to 15°C in the acetylene cooler 15 with 5°C water, and then enters the acetylene demister 16, and is sent to the conversion section after demisting. In the conversion section, after mixing with hydrogen chloride gas at a temperature of 15°C in the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com