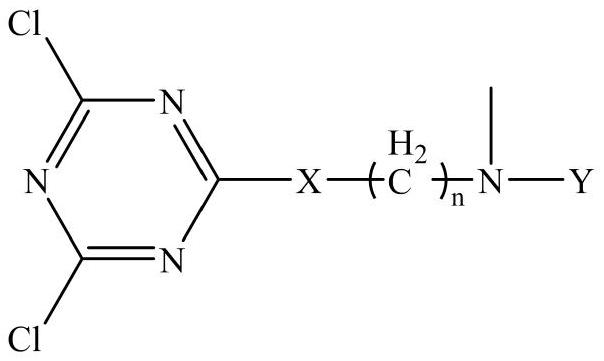

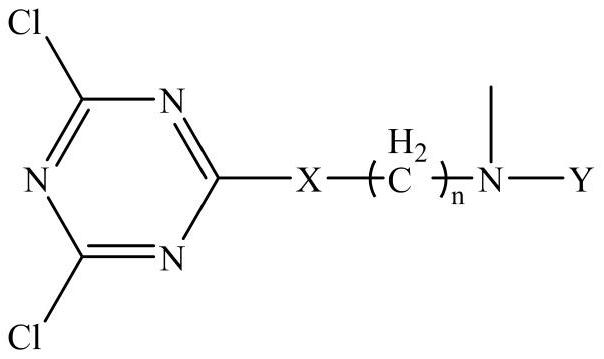

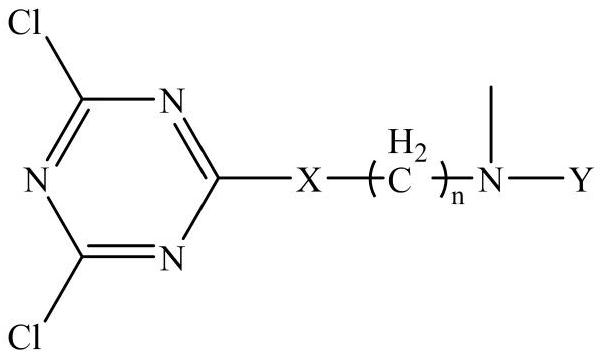

Cationic cyanuric chloride derivative tanning agent and preparation method thereof

A cyanuric chloride derivative and cationic technology, which is applied in the field of cationic cyanuric chloride derivative tanning agent and its preparation, can solve the problems that anionic dyes are not easy to be dyed, and the anionicity of crust leather is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention discloses a preparation method of a cationic cyanuric chloride derivative tanning agent, which comprises the following steps:

[0025] (1) In parts by mass, 9.22 to 36.88 parts of cyanuric chloride, 21.35 to 100.31 parts of solvent and 7.12 to 33.44 parts of deionized water were stirred and mixed uniformly in an ice-water bath to obtain mixture A;

[0026] (2) Add 2.98 to 20.44 parts of tertiary ammonia compounds dropwise to mixture A, maintain the temperature at 0 to 5°C, and obtain a mixed system after reaction; adjust the pH of the mixed system with an acid-binding agent solution until the pH is stable at 6.0 to 7.0 , continue to react for 4 to 6 hours to obtain mixture B;

[0027] (3) Filter the mixture B to obtain a filter cake. After washing the filter cake, vacuum-dry it for 4-6 hours under the conditions of a vacuum degree of 0.08-0.1MPa and a temperature of 20-25°C to obtain a solid C, which is ground and pulverized , to obtain white powder catio...

Embodiment 1

[0033] The invention discloses a preparation method of a cationic cyanuric chloride derivative tanning agent, which comprises the following steps:

[0034] 1) Add 9.22g of cyanuric chloride, 25.08g of acetone and 8.36g of deionized water into a reactor equipped with a stirrer and a thermometer, place in an ice-water bath and stir evenly to obtain mixture A;

[0035] 2) Slowly add 5.11 g of 3-dimethylaminopropylamine dropwise, keep the temperature at 0° C., and after the reaction, a mixture is obtained; constantly adjust the pH of the mixing system with a sodium carbonate solution with a mass concentration of 10%, until the pH of the system is stable at 6.5, React for 4 hours, discharge to obtain mixture B;

[0036] 2) Filter the mixture B, wash the filter cake with 3°C deionized water and acetone solution several times, and then vacuum dry the filter cake for 4 hours at a vacuum degree of 0.08MPa and a temperature of 25°C to obtain solid C, which After C is ground and pulveri...

Embodiment 2

[0038] The invention discloses a preparation method of a cationic cyanuric chloride derivative tanning agent, which comprises the following steps:

[0039] 1) Add 36.88g of cyanuric chloride, 100.31g of toluene and 33.44g of deionized water into a reactor equipped with a stirrer and a thermometer, place in an ice-water bath and stir evenly to obtain mixture A;

[0040] 2) Slowly add 20.44g of 3-dimethylaminopropylamine dropwise, keep the temperature at 5°C, and continuously adjust the pH of the system with a sodium hydroxide solution with a mass concentration of 30%, until the pH of the system is stable at 7.0, react for 4 hours, and discharge to obtain mixture B;

[0041] 2) Filter the mixture B, wash the filter cake with 0°C deionized water and acetone solution for several times, and then vacuum dry the filter cake for 6 hours under the condition of vacuum degree of 0.1MPa and temperature of 22°C to obtain solid C. After C is ground and pulverized, a white powder cationic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com