Device and process for synthesizing methanol based on hydrogenation of carbon dioxide

A technology for synthesizing methanol and carbon dioxide, which is used in the separation/purification of hydroxyl compounds, the preparation of hydroxyl compounds, and the preparation of organic compounds, etc., can solve the problems of low conversion rate and poor selectivity, and achieves reduction of emissions, improvement of conversion rate, and high economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

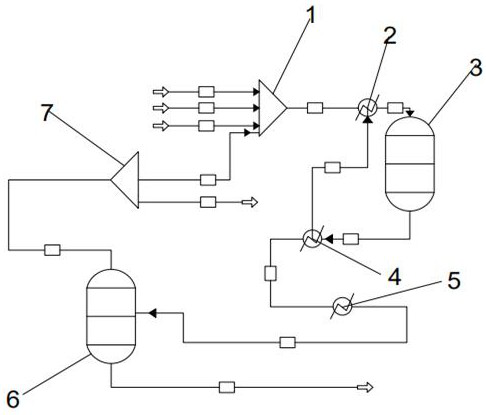

Method used

Image

Examples

Embodiment 1

[0040] Cu / ZnO / Al 2 o 3 Preparation of type copper-based catalyst:

[0041] 169.3gCu(NO 3 ) 2 ·3H 2 O, 59.5gZn(NO 3 ) 2 ·6H 2 O and 35.5gAl 2 (NO 3 )3·9H 2 O was dissolved in 1L of deionized water and preheated to 60°C, and 100g of oxalic acid was weighed and dissolved in 3L of deionized water and preheated to 60°C. Under vigorous stirring, add the mixed nitrate solution to the alkali solution dropwise, and keep 60°C constant, stop adding liquid when the pH is between 7 and 8, stir and age at the same temperature for 2 hours, and then use 60°C deionized water The precipitate was washed, the filter cake was dried overnight in an oven at 90°C, and calcined at 350°C for 2 hours. The obtained powder was pressed into tablets and crushed to 20-40 mesh to obtain a catalyst precursor.

[0042] The obtained catalyst precursor was heated at 200°C in H 2 Roasting under atmosphere for 5h, the final Cu / ZnO / Al can be obtained 2 o 3 copper-based catalysts.

Embodiment 2

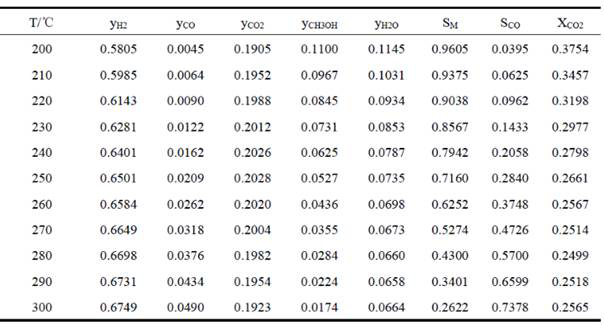

[0044] Utilize the Cu / ZnO / Al prepared by embodiment 1 2 o 3 Type copper-based catalysts for comparative simulation tests:

[0045] The effect of reaction temperature on the thermodynamic equilibrium of the system was studied by simulation, and the impact on CO 2 Effects on conversion and methanol selectivity. Through the above simulation, it provides a useful reference for improving the reaction conversion rate and reducing the energy consumption of the reaction process during the use of the carbon dioxide hydrogenation methanol synthesis unit.

[0046] Cu / ZnO / Al 2 o 3 The type copper-based catalyst is filled in the reactor to form a catalyst bed, and the temperature is raised to the reaction temperature. The molar ratio n(H 2 ) / n(CO 2 )=3, gas raw material CO 2 and H 2 After pre-mixing, preheat to 200°C, and then pass it into the reactor for catalytic reaction, the reaction volume space velocity GHSV is controlled at about 19000h -1 , the reaction pressure is contr...

Embodiment 3

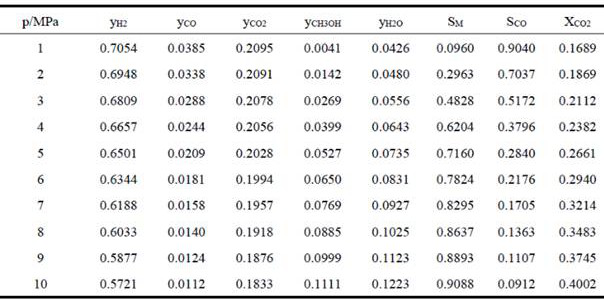

[0057] Utilize the Cu / ZnO / Al prepared by embodiment 1 2 o 3 Type copper-based catalysts for comparative simulation tests:

[0058] The effect of reaction pressure on the thermodynamic equilibrium of the system was studied by simulation, and the impact on CO 2 Effects on conversion and methanol selectivity. Through the above simulation, it provides a useful reference for improving the reaction conversion rate and reducing the energy consumption of the reaction process during the use of the carbon dioxide hydrogenation methanol synthesis unit.

[0059] Cu / ZnO / Al 2 o 3 The type copper-based catalyst is filled in the reactor to form a catalyst bed, and the temperature is raised to the reaction temperature. The molar ratio n(H 2 ) / n(CO 2 )=3, gas raw material CO 2 and H 2 After pre-mixing, preheat to 200°C, and then pass it into the reactor for catalytic reaction, the reaction volume space velocity GHSV is controlled at about 19000h -1 , the reaction temperature is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com