Preparation method of AlON powder, AlON powder and application of AlON powder

A powder and system technology, which is applied in the field of special ceramic preparation, can solve the problems of restricting wide application, optical anisotropy, and difficult processing, etc., and achieve the effect of preventing low purity, reducing surface properties, and improving sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

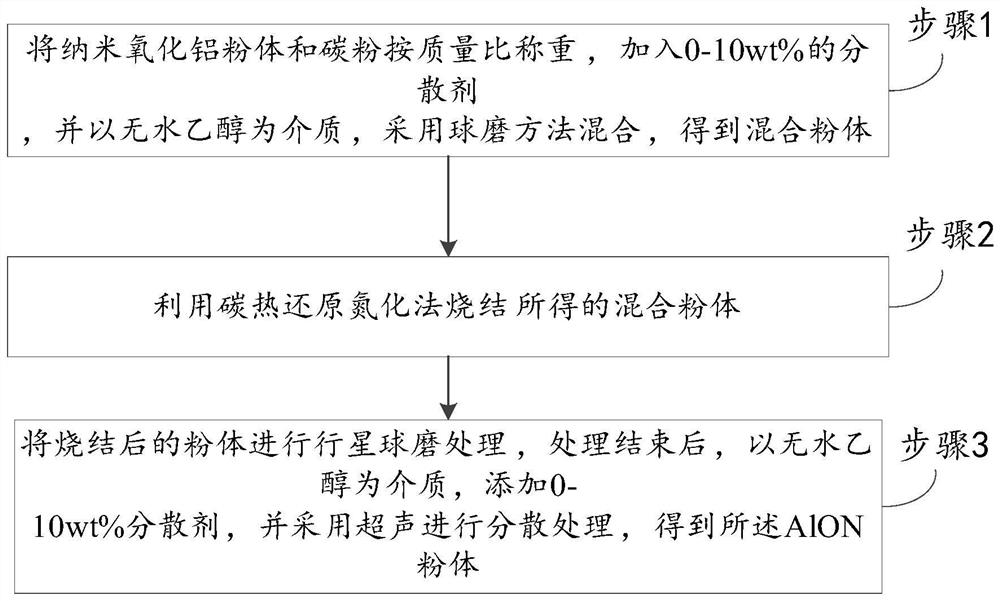

[0043] In a first aspect, the present invention provides a method for preparing AlON powder, such as figure 1 As shown, the method includes:

[0044] Step 1, weighing the nano-alumina powder and carbon powder according to the mass ratio, adding 0-10wt% dispersant, and using absolute ethanol as a medium, mixing by ball milling to obtain a mixed powder;

[0045] Step 2, using the carbothermal reduction nitriding method to sinter the mixed powder obtained in the above step 1;

[0046]In step 3, the powder sintered in the above step 2 is subjected to planetary ball milling treatment. After the treatment, 0-10wt% dispersant is added with anhydrous ethanol as a medium, and ultrasonic dispersion is used to obtain the AlON powder.

[0047] The present invention adds dispersant in step 1, has avoided the agglomeration of raw material in the mixing process and causes the homogeneity of mixed powder poor, and the AlON powder that is prepared has many impurities etc., and adds dispersant...

Embodiment 1

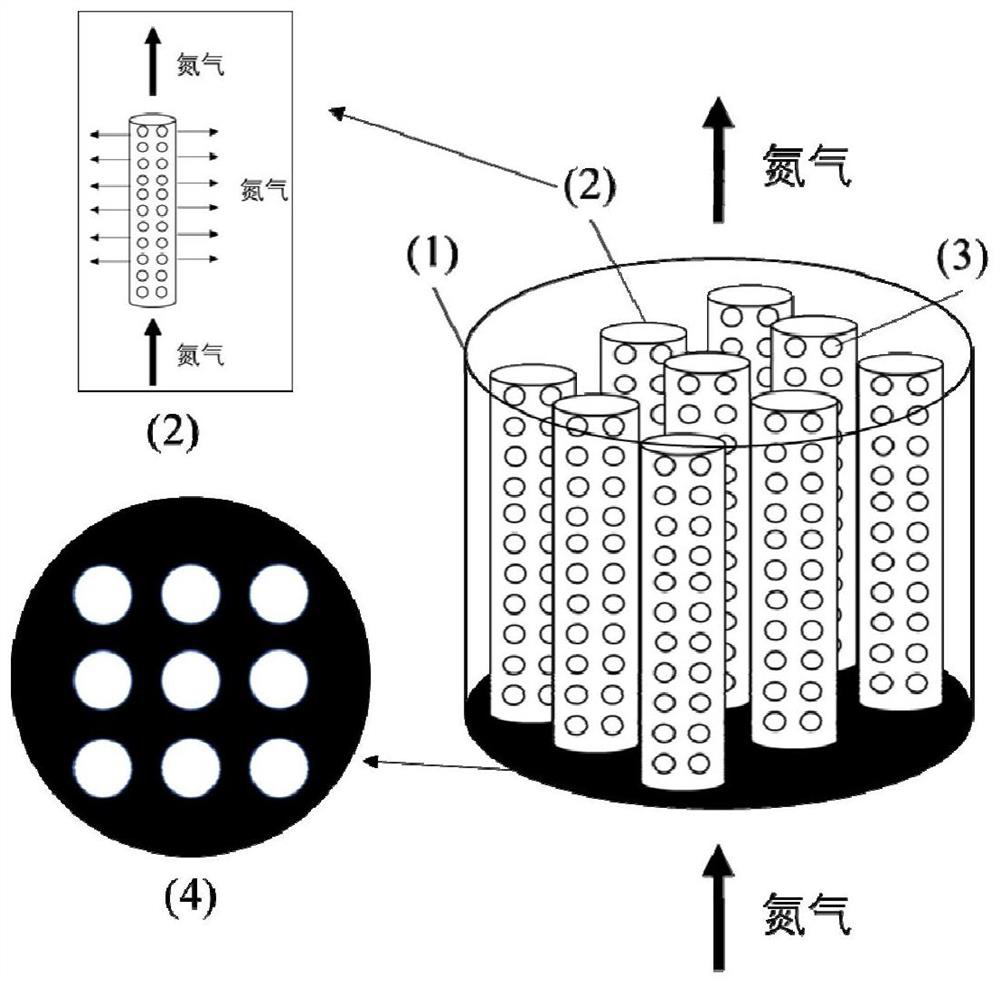

[0080] Alumina powder and carbon powder with a purity of 99.99% were weighed at a ratio of 94.2wt%: 5.8wt%, and 2wt% of D3005 dispersant was added, and mixed by planetary ball milling, wherein the ball milling medium was absolute ethanol at a speed of 200r / min, ball milling time 4h, then drying and sieving; the evenly mixed powder was transferred into a special boron nitride crucible, and a vacuum carbon tube furnace was used to synthesize the powder, specifically in a nitrogen atmosphere flowing at 10L / min The temperature rises to 1600°C and keeps warm for 60 minutes, then continues to rise to 1800°C, keeps warm for 60 minutes and then cools with the furnace; the powder is treated by planetary ball milling, the ball milling speed is 300r / min-400r / min, and the ball-to-material ratio is 10: 1. The ball milling time is 12 hours; then add absolute ethanol and 5wt% D3005 dispersant to the powder, use ultrasonic vibration for 10 minutes, and dry to obtain AlON powder.

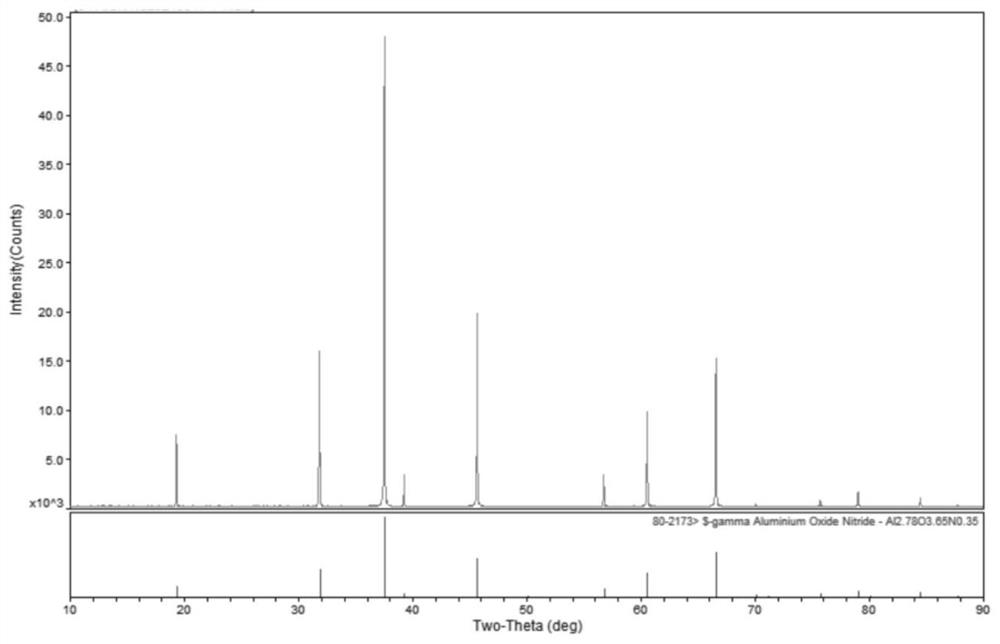

[0081] The...

Embodiment 2

[0083] Alumina powder and carbon powder with a purity of 99.99% are weighed at a ratio of 94.2wt%:5.8wt%, and 2wt% of A1101 dispersant is added, and mixed by planetary ball milling, wherein the ball milling medium is absolute ethanol, and the speed is 200r / min, ball milling time 4h, then drying and sieving; the evenly mixed powder was transferred into a special boron nitride crucible, and a vacuum carbon tube furnace was used to synthesize the powder, specifically in a nitrogen atmosphere flowing at 10L / min , the temperature rises to 1650°C, keeps warm for 30 minutes, then continues to rise to 1850°C, keeps warm for 30 minutes, and then cools with the furnace; the powder is treated by planetary ball milling, the ball milling speed is 400r / min, the ball-to-material ratio is 5:1, and the ball milling time is 8h; then add absolute ethanol and 5wt% A1101 dispersant to the powder, vibrate ultrasonically for 30 minutes, and dry to obtain AlON powder.

[0084] The AlON powder prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com