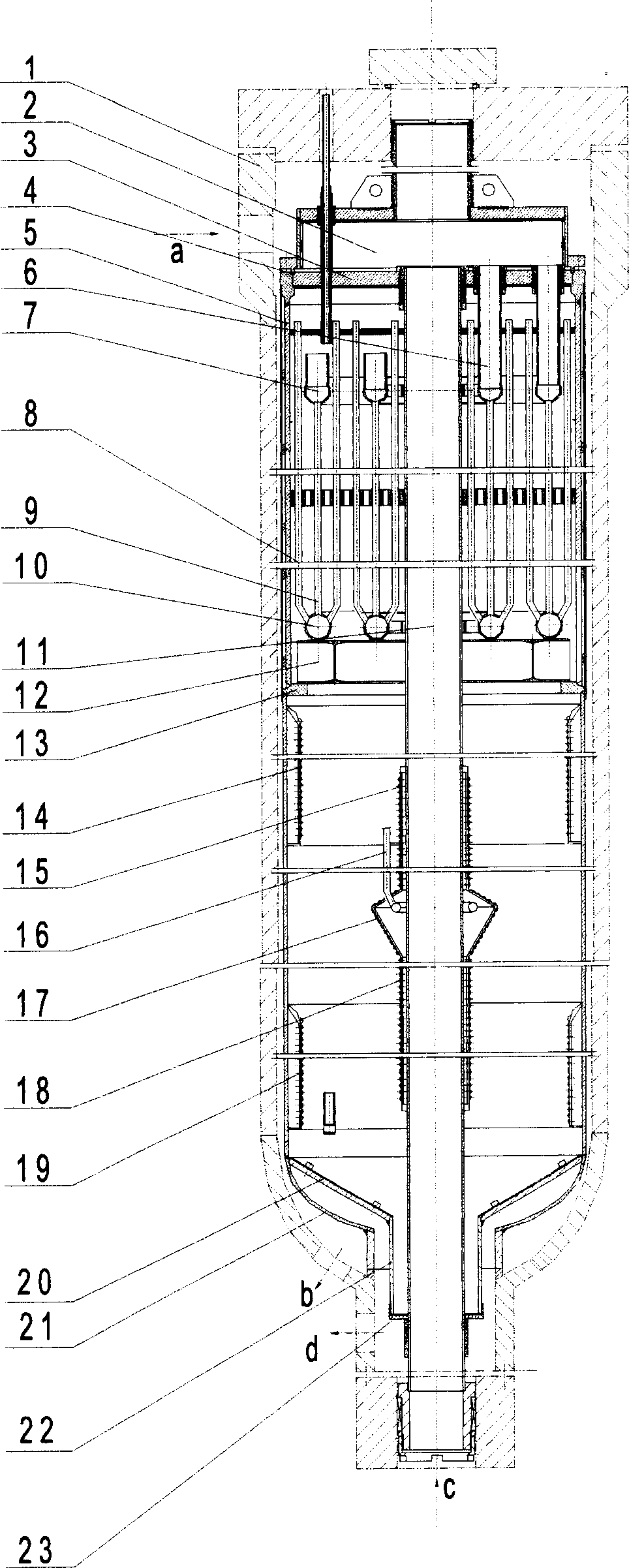

Front-placed type axial-radial synthesis tower

An axial-radial, front-end technology, which is applied in the synthesis reaction of ammonia, dimethyl ether, and medium-pressure combined alcohol production, can solve the problems of large power consumption of the cycle machine, large resistance of the synthesis tower, and non-recovery of reaction heat, etc. Achieve the effect of high heat recovery grade, lower tower resistance and high reaction heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] see figure 1 : consists of outer cylinder (1), gas collection box (2), cover plate (3), gasket (4), inner cylinder body (5), air induction pipe (6), upper ring pipe (7), descending cooling pipe (8), up cold pipe (9), lower ring pipe (10), center pipe (11), well frame (12), support ring (13), radial outer cylinder I (14), radial inner cylinder I (15), cold shock tube (16), diamond distributor (17), radial inner cylinder II (18), radial outer cylinder II (19), conical flower plate (20), lower head support (21), catalyst discharge pipe (22), bulkhead (23) constitute the synthesis tower, wherein parts (2) ~ (23) form the inner cylinder, and parts (6) ~ (10) are welded into a single tube baffle cooling Tube tube, a cover plate (3) is provided between the gas collection box (2) and the cold tube tube, and the air-leading tube (6) of the cold tube tube is connected to the gas collection box (2) and the cold tube tube, and the cold tube tube Supported on the inner cylinder wa...

Embodiment 2

[0022] DN1200 alcohol synthesis tower, filled with C 207 Type Catalyst 11.5m 3 , cold pipe area 140m 2 . The tower inlet pressure is 12.0MPa, and the tower gas volume is 115000Nm 3 / h, of which the amount of cold shock gas ~ 25000Nm 3 / h. Into the tower gas composition: H 2 : 70.1%, CO: 4.2%, CO 2 : 0.5%, N 2 : 24.1%, CH 4 : 1.1%. The bed temperature is 230°C, the tower gas is 240°C, and the tower gas pressure is 11.6MPa. The production of sperm alcohol is 4.5t / h, and the by-product of ~0.5MPa steam is 2.4t / h.

[0023] The remaining structures and implementation methods of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com