A discharge module based on surface catalytic thin film to enhance ozone synthesis

A thin film and ozone technology, applied in the direction of ozone preparation, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problems of increasing the difficulty of ozone generator operation and transportation, so as to improve the efficiency of ozone synthesis and improve Ozone concentration and efficiency, the effect of avoiding the increase of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

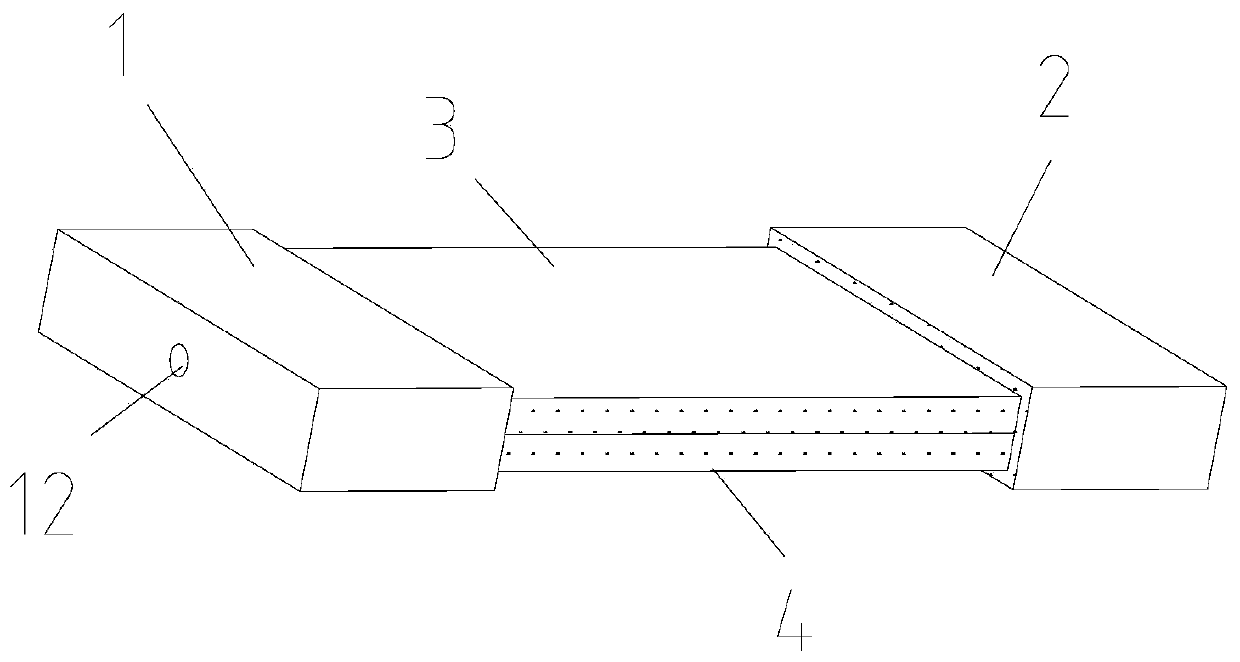

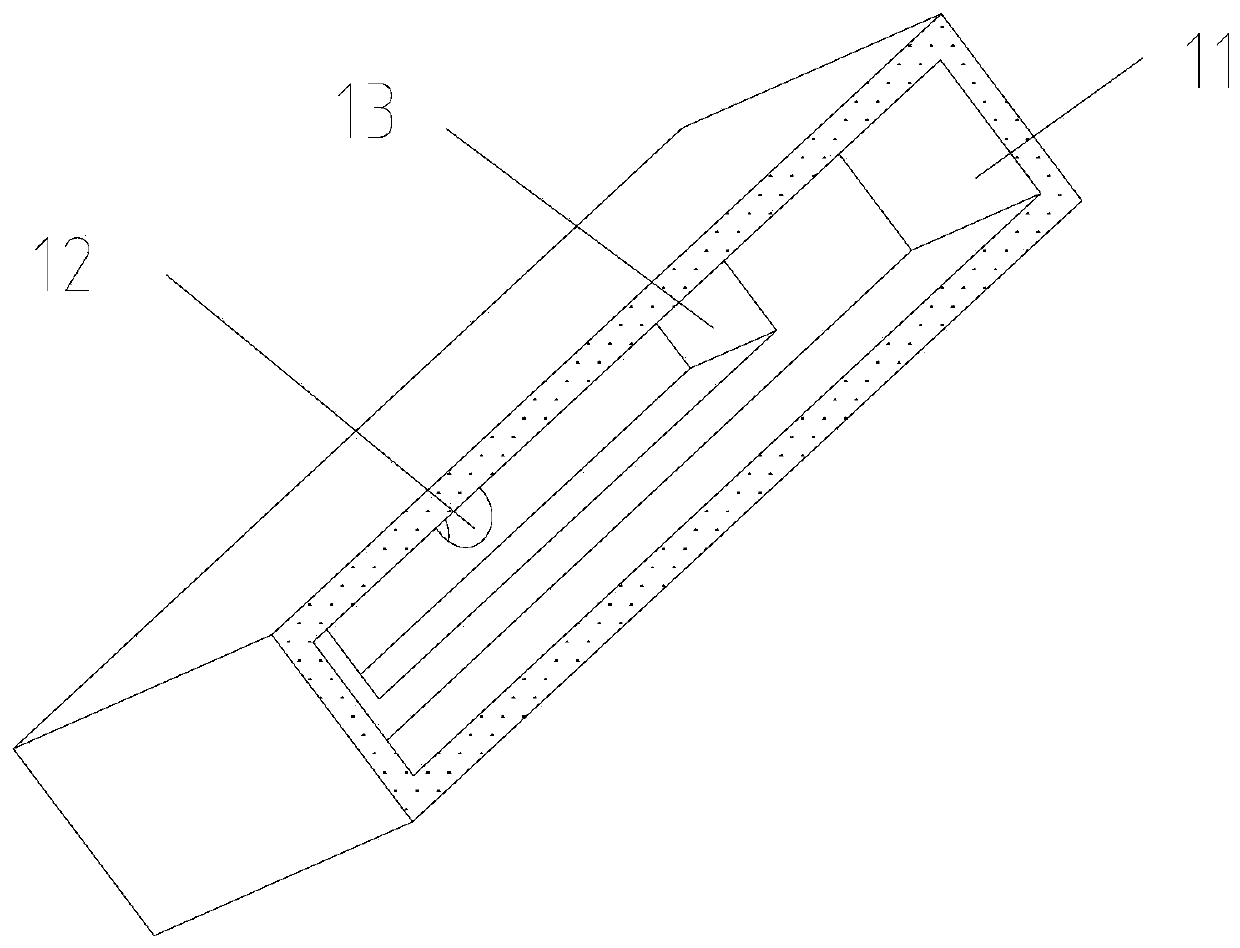

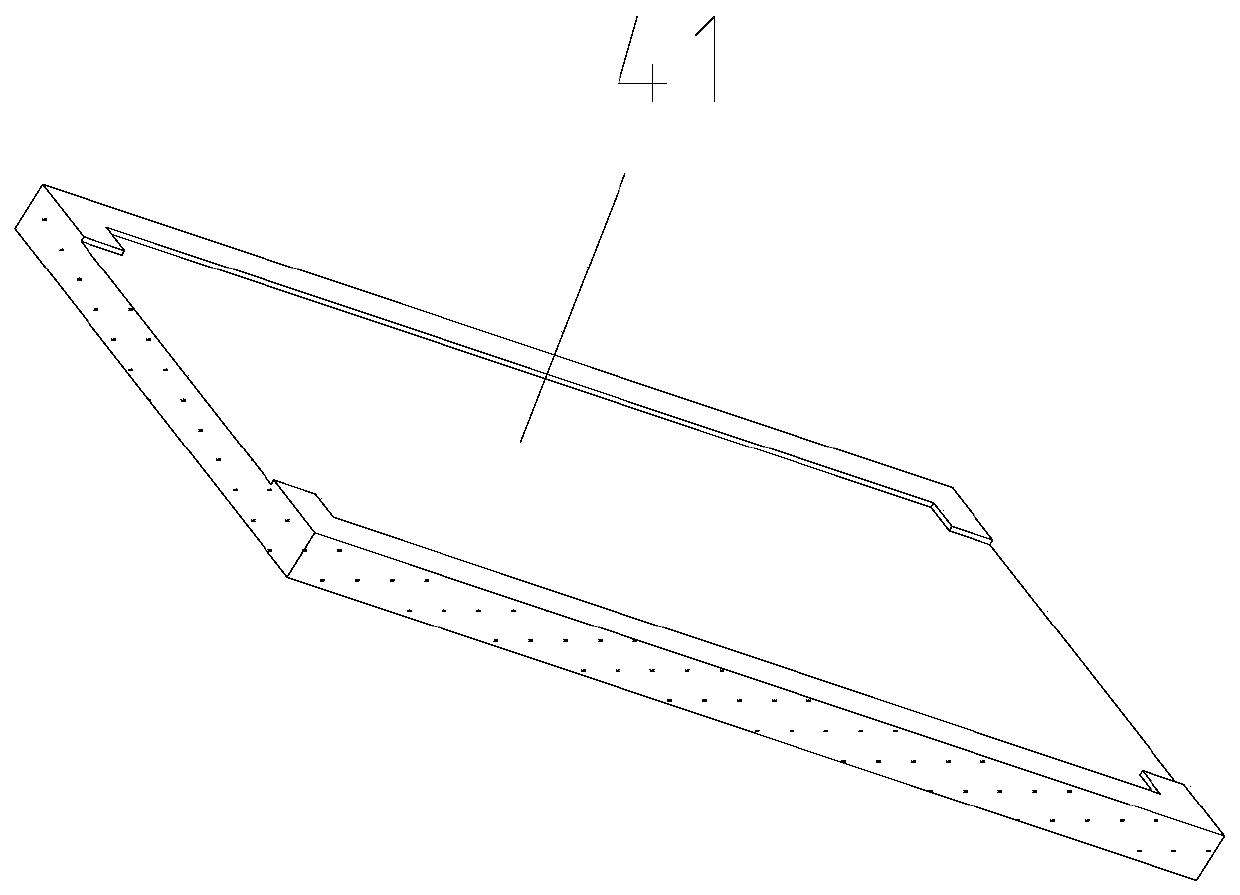

[0078] Such as Figure 1-7 , 9, a discharge module based on surface catalytic thin film enhanced ozone synthesis, including a discharge unit packaging plate, a ventilation element I1 socketed on the inlet end of the discharge unit packaging plate and an air outlet socketed on the discharge unit packaging plate The ventilation element II2 at the end; the ventilation element I1 and the ventilation element II2 have the same structure;

[0079] One end of the ventilation element I1 has a sealed cavity I11 matching the air inlet end of the discharge unit packaging plate, and the other end of the ventilation element I1 has an air inlet 12, and the air inlet 12 passes through the gas buffer zone The cavity I13 communicates with the sealed cavity I11;

[0080] One end of the ventilation element II2 has a sealed cavity II matching the gas outlet end of the discharge unit packaging board, and the other end of the ventilation element II2 has an air outlet hole, and the air outlet hole p...

Embodiment 2

[0109] Such as Figure 10 As shown, a discharge module based on a surface catalytic film to enhance ozone synthesis, which differs from the discharge module based on a surface catalytic film to enhance ozone synthesis described in Example 1 is that only one electrode is coated on the surface of the grid-shaped metal electrode 43 Layer semiconductor thin film 8.

[0110] Similarly, the ozone synthesis effect of the module described in this embodiment was tested by taking the pure oxygen source as an example, and the results were compared with the ozone synthesis effect of the module without semiconductor film, the conventional bulk phase and the dielectric barrier discharge module along the surface ,Such as Figure 12 Shown to verify the superiority of this embodiment. The comparison results show that. Under the same conditions, the ozone synthesis concentration and efficiency of the modules described in this embodiment are also much higher than the results of modules withou...

Embodiment 3

[0112] Such as Figure 8 , 11 As shown, a discharge module based on surface catalytic thin film enhanced ozone synthesis, which differs from the discharge module based on surface catalytic thin film enhanced ozone synthesis described in Example 1 is characterized in that the lower surface of the dielectric layer I32 and the grid-shaped A layer of semiconductor film 8 is coated on the surface of the metal electrodes 43 .

[0113] Similarly, the ozone synthesis effect of the module described in this embodiment was tested by taking the pure oxygen source as an example, and the results were compared with the ozone synthesis effect of the module without semiconductor film, the conventional bulk phase and the dielectric barrier discharge module along the surface ,Such as Figure 12 Shown to verify the superiority of this embodiment. The comparison results show that. Under the same conditions, the ozone synthesis concentration and efficiency of the modules described in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com